Lightweight Aggregate Plays a Key Role in Pier Expansion

To expand Port Canaveral’s Cruise Terminal 3 (CT-3) in Florida, the project’s engineers needed something akin to a miracle – a cost-effective way to create structurally secure land where there was only ocean. To solve the technical constraints of the rebuild, the engineers turned to a lightweight geotechnical fill made from a rotary kiln-produced expanded shale, clay, and slate (ESCS). The unique physical properties of ESCS lightweight aggregate reduced applied vertical stresses and lessened the lateral force acting on the steel bulkhead wall system. In addition, the decreased loading on the structure allowed the design team to reduce the gauge and diameter required for the supporting pipe piles in the steel bulkhead wall system.

However, before realizing the benefits of lightweight aggregates, the design team first evaluated the cost; the manufacturing process makes lightweight aggregate more expensive to produce than natural quarried fill material. Despite the 155-million-dollar project budget, those overseeing the expansion needed to know how each material choice affected the project’s overall cost. So why did the engineers use a material that was so much more expensive out of the gate than other options?

While lightweight aggregate costs more to produce, it provided other savings in the wharf structure that helped the CT-3 project stay within budget, reducing shipping costs, compaction efforts, and the support systems’ construction costs. Lightweight aggregate contributed to both material and labor savings due to its inherent low density and high internal friction angle.

Before diving into how lightweight aggregate helped engineers achieve the performance needs of the project while keeping construction costs within budget, it is important to outline the specifics of the expansion.

A Big Project!

Since the 1950s, Port Canaveral has played a vital role in Florida’s trade and tourism industries. Sitting at the intersection of North-South and East-West roadway corridors, the port was founded to facilitate commercial fishing and cargo trade before being expanded in the 1980s to also host cruise ships.

In 2018, as a part of the port’s 30-year strategic master planning process, the growth of the port’s cruise business was outpacing the infrastructure capacity. As a result, the port demolished the outdated and underutilized CT-3 to construct a new cruise terminal complex to continue serving its community. The construction plans included a 188,000-square-foot terminal structure, a new parking garage, and an expanded berth to accommodate the world’s largest cruise ships, including the recently launched Carnival Cruise Line’s Mardi Gras, the largest cruise ship in the Carnival fleet to date. Because of CT-3’s location in the port, expanding the old berth to the requisite 1,309 linear feet required engineers to push into the ocean, creating land where there had been only water. This was destined to be the largest single construction project in the port’s 70-year history.

Using a value engineering approach, the engineers and port authority recognized that lightweight aggregate would not only solve several technical aspects of the project but would also reduce adjacent system costs, allowing the project, when examined as a whole, to remain within budget.

Efficiency Delivers Value

Expanding CT-3 to the desired specifications required approximately 60,000 cubic yards of geotechnical fill and presented the first construction hurdle. From shipping logistics to scheduling site delivery, the sheer quantity of material needed could cause longer construction durations and labor wastes as crews would have to partially stop construction to store the material and then carry it from its staging area to the terminal itself. The aggregate was shipped by rail to Florida, where it was unloaded onto trucks 15 miles from the project site. The lightweight aggregates’ comparatively low density reduced both the shipping costs and the number of railcar-to-truck transfers and truckloads delivered to the project site, making delivery logistics easier.

Whereas traditional quarried materials have a typical dry loose bulk density of 95 to 135 pounds per cubic foot, lightweight aggregates typically weigh between 35 to 55 pounds per cubic foot. This significantly reduced the number of railcars and trucks needed to carry the material from the manufacturer to the site. For example, depending on the material, a standard 20-ton dump truck can carry between 10 to 16 cubic yards of traditional geotechnical fill. As a result, delivering the required materials from the unloading site to CT-3’s construction staging area would take approximately 4,000 truckloads. By comparison, that same dump truck can carry up to 32 cubic yards of lightweight aggregate, reducing the required truck loads by 50 to 68 percent. A similar benefit is realized with the railcars.

Lightweight aggregate reduced the direct cost of shipping the fill material. It also streamlined the process, minimizing costs associated with coordinating shipping logistics, material handling, and onsite delivery. The reduced shipments also helped ensure that this part of the project would not be delayed. This way, lightweight aggregate started recovering its initial cost before it arrived on site.

Lightweight Aggregate’s Slight Edge

When the material arrived, it continued to provide cost-saving benefits. Placing lightweight aggregate requires no specialized equipment. Instead, contractors can use the same earthwork equipment, such as standard loaders, rollers, and plate compactors, to work with the material as they would with traditional quarried geotechnical fills.

Due to the angularity and gradation of ESCS lightweight aggregates, the compaction effort required to achieve a suitable density is typically less. The objective of compaction of lightweight aggregate fills is to reach an optimal ratio of high stability and density. Accordingly, the material needs fewer passes from compaction equipment, which increases productivity. Over time, these savings can compound by reducing potential maintenance costs that could arise if natural aggregate were used for fill. In addition, the lower applied vertical pressures from lightweight fill also reduce potential settlement over time, leading to lower maintenance costs for the new wharf.

Reducing Adjacent System Costs

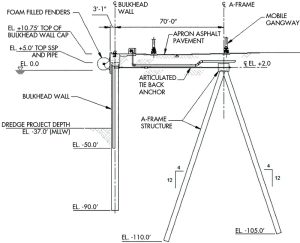

In addition to reducing shipping, placing, and compaction costs, lightweight aggregate helped the CT-3 expansion project team reduce the gauge and diameter of the steel pipe piles in the bulkhead wall system. Lightweight aggregate made from expanded shale, clay, and slate contains air pockets throughout, creating a low-density and porous material. The manufacturing process produces a very angular material, contributing to a high internal friction angle and reduced lateral force on the support system.

Lightweight aggregate’s low-density and high internal friction angle, which can exceed 45 degrees, significantly reduces lateral earth pressure and fill dead loads compared to natural quarried fill materials, which typically have an internal friction angle between 30 and 38 degrees. Leveraging this benefit from the lightweight aggregate fill, the CT-3 design team was able to reduce the diameter and gauge of the pipe piles used for the wharf combi-wall and the A-frame tie-back anchor system providing considerable cost savings to the owner.

Benefits Beyond Pier Construction

CT-3 was completed in mid-2020 and can now accommodate today’s massive cruise ships. As travel restrictions from COVID-19 lift, the terminal is seeing the fruits of a value engineering approach. With almost a year and a half of successful cruise sailings from Port Canaveral, including several by the cruise ship Mardi Gras, the expanded CT-3 is quickly cementing Canaveral’s status as the second busiest cruise port in the world – with thousands of cruise passengers passing through every month.

ESCS lightweight aggregate’s low density and high internal friction angle helped engineers reduce the costs of the structural marine components of the terminal expansion. Furthermore, the ESCS manufacturing process produces a vitrified and durable product that will not degrade, contributing to the longevity of the new cruise terminal for Port Canaveral.

The benefits realized from using lightweight aggregate on this project can also be translated to other projects. For example, whether or not a project needs to create land where there is only water, lightweight aggregate can help engineers and contractors reduce the costs of lateral support structural systems.■