The New York State Thruway bridge across the Schoharie Creek collapsed on April 5, 1987, during a flood, killing 10 people. Unlike many of the failures discussed previously, this was in the lifetime of many readers.

The Schoharie Creek has its headwater at the foot of Indian Head Mountain in the Catskill Mountains and flows 93 miles in a general northerly direction, meeting the Mohawk River at Fort Hunter. It has a watershed area of approximately 1,000 square miles and, while normally a small creek, it has a history of major flooding. Over the years, the creek was crossed by many bridges washed away by floods and the Erie Canal. A review of the impact of the Creek on the original and the 1842 enlarged Canal illustrates the destructive power of flooding. The original Erie crossed the creek at Ft. Hunter on a pond impounded by a low-level dam in 1822.

The mules would be loaded on the canal boat winched to the other side. Later, a small bridge was built for the mules to walk, pulling the canal boat across the creek. Unfortunately, that dam was flooded out in 1832. When the enlarged canal was built, the creek was crossed with an aqueduct around 1842. A major flood destroyed another dam built downstream from the Aqueduct in 1864. The Aqueduct was, in turn, damaged by significant flooding in 1869, in 1879, and still later in 1894. The Gilboa Dam was built in 1927 to create a reservoir to hold water for New York City and provide some flood control downstream. It is clear from the historical record that the Creek was a major threat to any structure built over or in its path.

Moving upstream from its intersection with the Mohawk River are the remains of the Aqueduct, two steel bridges carrying Route 5S, followed by the Thruway Bridge. Farther upstream, the famous Blenheim Bridge crossed the creek. It was built in 1855 by Nichols Powers and was the longest span covered bridge in the country for many years until it was washed away in 2011 by tropical storm Irene. It has since been rebuilt.

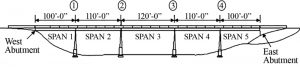

The New York State (aka Thomas E. Dewey) Thruway was built from New York City to Buffalo in the mid-1950s and is part of the Interstate Highway System with Numbers I-87 from New York to Albany and I-90 from Albany to the Pennsylvania State Line. The firms Madigan-Hyland (M-H) and Pavlo Engineers were chosen to design the Schoharie Creek bridge and many others on the road. They chose two options as to the length of the bridge. The first was for a 600-foot-long bridge and the second 540 feet. The state chose the shorter length that would require filling in some of the creek channel. The final length of spans were 100, 110, 120, 110, and 100 feet. The bridge was designed following the 1949 edition of the American Association of State Highway Officials (AASHTO) Standard Specifications for Highway Bridges.

The design was approved in January 1952 and was very similar to other Thruway bridges, consisting of two steel girders supporting cantilevered crossbeams that supported steel stringers on which an 8-inch-thick reinforced concrete deck was placed. This gave a total width of deck of 112 feet 5 inches. The foundations consisted of spread footings on top of which was placed a concrete plinth. On top of the plinth were two concrete columns supporting a connecting concrete beam. On February 11, 1953, the construction contract was awarded to B. Perini and Sons, Inc. (Now Perini Corporation) of Boston.

It is of interest that the then-current AASHTO standards called for a careful study of local conditions, including flow (discharge) and frequency, the performance of other bridges in the vicinity, and other information pertinent to the design of the bridge and likely to affect the safety of the structure. After the collapse, in response to written questions from the National Transportation Safety Board (NTSB), the bridge designer, Pavlo, stated that he did not study the history of Schoharie Creek before preparing the final design. Madigan-Hyland Consulting Engineers, who developed the preliminary plans, design plans, specifications, and quantity/cost estimates, conducted a limited hydraulic review as indicated by its hydraulic sheet. However, the sheet did not call for comments, nor were comments added concerning the creek’s flood history or the performance of structures along the creek during previous floods, even though some of the information was readily available. Given the well-documented history of flooding of the Schoharie Creek, this was possibly the fatal error leading to the bridge’s failure.

The bridge opened to partial traffic in the summer of 1954 and was fully opened in October. Shortly after it opened, cracking of the plinth was noted and required repair. Almost as a test of the bridge, a 100-year flood of 76,500 cfs roared down the creek in 1955, resulting in no visible damage, but it is thought that the floodwaters may have undercut (scoured) the foundation. “There were several other problems that occurred shortly after the completion of the bridge. Inspectors noticed that the expansion bearings were out-of-plumb, roadway approach slabs had settled, roadway drainage was poor, and the supporting material for west embankment dry stone pavement was deficient.” All of the problems mentioned and other minor problems were corrected by the fall of 1957.

The spring of 1987 was very wet for upstate New York and New England. Over six inches of rain had fallen on April 3rd and 4th, and, coupled with snowmelt, water came roaring down the creek on April 5 in what was determined to be a 50-year flood. Pier No. 3 was washed out around 10:45 AM, and spans 3 and 4 dropped into the creek. With debris in the channel, the flow was directed to Pier No. 2, which also was washed out, and span 2 dropped into the creek. At the time of the collapse, there was one car and a tractor-trailer on the bridge, and before traffic could be stopped, three more cars ended up in the creek. A total of 10 people lost their lives in the disaster. The body of the tenth victim was found two years later downstream in the Mohawk River.

As is always the case, people and politicians want to know what caused the failure and loss of life. The Thruway Authority hired the firms of Wiss, Janney, Elstner Associated of Northbrook, Illinois, and Mueser Rutledge Consulting Engineers of New York City to investigate. In addition, the NTSB conducted its own study of the failure. A fourth investigation was undertaken by Thornton-Tomasetti, PC, of New York for the New York State Disaster Preparedness Commission. They all agreed that scour undermined Piers No. 2 and 3, leading to the disaster as a hole approximately 9 feet deep and 25 to 30 feet long had formed, and the spread footing simply slid into the hole. Some conclusions were,

- The shallow footings used, bearing on soil, could have been undermined. Therefore the depth of the footings were not enough to take them below the probable limit of scour.

- The foundation of Pier 3 was bearing on erodable soil. Layers of gravel, sand, and silt, interbedded with folded and tilted till, allowed high-velocity floodwaters to penetrate the bearing stratum. Riprap protection, inspection, and maintenance were inadequate.

In addition, it was found that the riprap stone was smaller than required and that sheet piling around each pier, intended to be left in place, had been removed.

Thornton-Tomasetti also found,

- The flood was greater than that anticipated by the designers and followed the 1955 flood and others that had disturbed the riprap.

- A curve in the river upstream of the bridge directed a higher-velocity flow toward Pier 3.

- Drift material, caught against the piers, directed water downward at the base of Pier 3.

- Berms, built in 1963, directed floodwaters under the bridge.

- An embankment west of the creek channel increased flood velocities.

- The Mohawk River dam downstream was set for winter conditions and was 3 meters (10 feet) lower than in the 1955 flood, increasing the hydraulic gradient.

The NTSB, which was very critical of state employees and their consultants, reported in part,

Correspondence between M-H and the DPW [Department of Public Works] relating to hydraulics usually addressed the length of the bridge and the elevation of the backwater, but not the frequency and magnitude of previous floods or their effects on other structures over the Schoharie Creek. [they didn’t] mention [any] of the three floods that exceeded 50,000 cubic feet per second (cfs), which occurred during the first half of the 20th century, let alone an analysis of their importance to the design and construction of the bridge.

[Madigan- Hyland’s] failure to review the available history limited its appreciation for the potential for scour at this bridge site. If M-H had visited some of the other structures along the creek, such as the Aqueduct 3,000 feet north of the bridge, it probably could have observed scour near the piers, and this may have heightened its concern for scour.

The NTSB then went on for five paragraphs criticizing the elevation of the base of the spread footings as being too high based on boring data. They then discussed the scour situation again and the use of piles as a means of minimizing scour effects, writing,

Based on this collapse, as well as on an improved understanding of hydraulics and an improved ability to predict scour, the Safety Board believes that AASHTO should modify its requirements for the depth of the footings… and require that the depth be based on estimates of the maximum potential depth of scour at the bridge site, rather than on the existing streambed elevation.

Scour piles may have provided the stability needed for the substructure to withstand the scour of the 1987 flood since the maximum scour depth observed at the bridge site was 9 feet below the bottom of the footing of pier 3…However, since the Safety Board cannot be certain how deep the scour hole at pier 3 may have become had spans 3 and 4 not fallen when they did, it is not possible to conclude that piles driven in accordance with the AASHTO recommendations for pile depths would have prevented the bridge collapse. Certainly, if piles were driven deeply enough, the piers would not have lost their support. Therefore, the Safety Board concludes that had the Schoharie Creek Bridge been designed with piles to protect against scour, the collapse might not have occurred, depending on how deeply the piles were driven below the footings…

They concluded in this section, “Thus, the Safety Board believes that section 4.3.1.2 should be modified to require that the depth of piles exceed the predicted maximum potential depth of scour.” They then got into the importance of riprap and the fact that all inspections downplayed the importance of riprap and concluded that state inspectors, and their superiors, did not seem to know whether the footings were on piles or not.

When the Schoharie Creek Bridge was designed and built, riprap was a recognized means of protecting scour, and riprap was specified in the contract. Without piles, the integrity of the bridge foundation depended entirely on the maintenance of riprap for protection against scour.

The NTSB concluded in this section “that had the piers been protected by riprap at the time of the April 1987 flood as they were during the 1955 flood, the bridge probably would not have collapsed.” They then discussed the inspection and criticized everyone who was or should have been involved with the in-depth inspection. Some of their statements are as follows.

The inspections in the New York State Thruway Authority (NYSTA) Albany division were accomplished not by engineers but by personnel whose primary responsibilities were in bridge maintenance. The Albany assistant division engineer (bridges) was not a professional engineer…

However, in his 1986 inspection of the bridge and previous inspections, the Albany assistant division engineer (bridges) failed to evaluate the condition of the riprap at the piers properly, and he failed to take the dropline readings necessary to evaluate the conditions in the streambed…The fact that he overlooked these two tasks indicated that he either did not think they were important or did not understand their importance. In addition, the engineer’s supervisors, who should have reviewed his reports, apparently did not review his reports or failed to recognize the seriousness of the omissions and therefore did not attempt to correct the situation.

The Albany assistant division engineer (bridges) may have assumed that the bridge piers were built on piles and therefore did not regard riprap maintenance as important…At the Safety Board’s public hearing, he also indicated that he thought the bridge was constructed on piles…

The Albany assistant division engineer (bridges) said that he did not recall riprap ever having been placed or maintained around the pier footings…

In 1979, an engineering firm conducted bridge inspections for the New York State Department of Transportation (NYSDOT) to comply with the National Bridge Inspection Standards (NBIS) inventory requirements for off-system bridges…The measurements and photographs from the inspection clearly indicated that riprap was not piled at an even level around the plinth. This information should have alerted a person knowledgeable in river mechanics and structures that riprap had moved, posing a danger to the structure…

The Safety Board believes that the sketches showed that a significant amount of riprap had moved away from the upstream ends of the piers in 1979 and, especially since there were no piles, the engineering firm should have, in accordance with its agreement with the NYSDOT, immediately called the NYSDOT project manager to alert him…

When the NYSDOT received the report, it did not notify the NYSTA of the missing riprap, indicating either that NYSDOT personnel did not review the report or that they believed the missing riprap required no attention.

When the NYSTA finally received the report in April 1980, it did not replace the missing riprap, indicating either that it also did not review the report or that it did not consider the situation serious enough to require correction…In 1982, a major rehabilitation project greatly improved the superstructure and substructure …Unfortunately, the plans finalized by the NYSTA did not call for the replacement of missing riprap with 600 cubic yards of 600-pound riprap, as had been specified in these plans. Replacement riprap was removed from the plans at the direction of the NYSTA technician responsible for finalizing the plans.

When a technician decided to delete riprap from the final plans, these same supervisors either checked the plans and agreed with his decision, or they did not check the plans. The Safety Board believes that a failure of the supervisor to review this decision would have been a major deficiency in his oversight of a subordinate. In either case, however, the decision not to replace the riprap was a critical decision that contributed to the cause of the accident.

The Safety Board is concerned that bridges similar to the Schoharie Creek Bridge may not be receiving proper riprap maintenance because there is no proper guidance as to when to replace riprap…The Safety Board is thus convinced that specific guidance must be provided to bridge inspectors.

The Safety Board believes that research is needed to determine the size and amount of riprap needed for scour protection and the degree of depletion that may occur before replacement is necessary…

Therefore, the National Transportation Safety Board recommends that the American Association of State Highway and Transportation Officials:

Revise section 4.4.2.1 of the Standard Specifications for Highway Bridges, removing any reference to a minimum depth of 4 to 6 feet for bridges over water and stating instead that the minimum depth of footing be based on historical data for scour at or near the bridge site and mathematical analyses of maximum potential scour depth.

Modify section 4.3.1.2 of the Standard Specifications for Highway Bridges to require that the depth of piles exceed the predicted maximum potential depth of scour.

Provide specific guidance on maintenance of foundations of bridges that are dependent upon riprap for scour protection to specify that following each inspection, the riprap be replenished to meet the design specifications.

Issue an addendum to the Manual for Bridge Maintenance- 1987 that strongly cautions the user that the chart on page 160, which is a “rough guide to the selection of an adequate stone size at bridge crossings,” is probably inadequate to ensure that all the riprap will remain in place under the average velocities listed; issue an errata sheet to correct previous editions.

In conclusion, the failure of the Schoharie Creek Bridge can be traced to bad design, bad construction, bad inspection, lax supervision, etc. However, it did have a positive effect in instituting periodic underwater investigations to determine the extent, if any, of bridge scour and bringing a greater awareness of the potential problem to the designers of bridges over rivers, streams, and creeks. In February 1991, the FHWA issued Hydraulic Engineering Circular, HEC, No. 18, Evaluating Scour at Bridges. Ten lawsuits against the Thruway Authority were filed from relatives of those who died in the collapse. They were settled for a total of approximately $4,000,000. The Authority then sued the bridge contractor and designer, but the statute of limitations had expired on the contractor. They later settled with the designers for $600,000.

This is the last in the series on bridge failures. Recent failures such as the Minneapolis I-35, Pittsburg (Frick Park), and Florida International University pedestrian bridges are still being studied and debated. A new series on 19th Century bridges across the Mississippi River will be published in future issues.■