The Earthquake-Resisting System that Surprised the Profession

This is one of a series describing surprising lessons engineers have learned from earthquakes and, in particular, the January 17, 1994, Northridge earthquake. Engineers have been learning from earthquakes for more than 100 years by observing the patterns of damage earthquakes have caused in the built environment. Sometimes, things only partly true were part of the lesson, discovering the mistake only after a later earthquake causes unexpected damage. Such was indeed the case with steel moment frame structures and the 1994 Northridge earthquake.

Steel framing was first used for building construction in the 1880s when it became a popular construction system for long-span industrial structures and the new “high rise” buildings that began to spring up in major cities. The invention of the elevator safety break by Elisha Otis made high rise construction practical. However, unreinforced masonry bearing wall construction could not practically extend beyond 5 or so stories, as the weight of the masonry would exceed its strength. Engineers turned to a transitional masonry construction wherein steel frames were provided to bear the building’s weight, while relatively thin masonry walls provided enclosure and interior partitioning. These early steel frames used built-up steel box and wide flange sections, constructed of rivet-connected plates and angles. Beam-to-column connections comprised riveted top and bottom seat angles as well as heavier bracketed connections, both of which provided moment-resistance, albeit as partially-restrained, partial strength joints. Engineers often designed the beams as simply supported for gravity loading and fixed-ended for wind resistance and, indeed, the heavier beam-column connections were often designated as “wind connections” on drawings. The masonry walls which provided most of the actual lateral resistance in these structures were considered architectural and neglected. In April 1906, a large number of these structures were subjected to strong earthquake shaking, and then fire, in the great San Francisco earthquake. Engineers observed the remarkably good performance of these high-rise steel frames compared with other structures (Figure 1). Similar superior performance was observed in later earthquakes, including the 1926 Santa Barbara and 1933 Long Beach events.

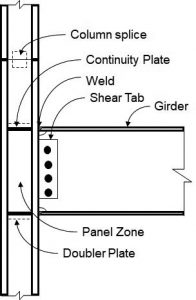

Construction technology changed little in the next 30 years; then further development was abruptly halted by the Great Depression followed by World War II. After the war, unreinforced masonry construction became uneconomical and, in California, was not permitted by code following the 1933 Long Beach earthquake. Some steel structures were constructed with cast concrete walls replacing the masonry. However, architectural styles evolved favoring glazed curtain walls, and the steel frames had to rely on more compact moment resisting connections for lateral resistance. Riveted connections gave way to bolted varieties, with WT sections replacing angles and brackets as connection elements. As design forces began to exceed the practical capability of bolted connections, welding, first introduced in the shipbuilding industry, found its way into building construction. By the 1960s, engineers commonly designed connections employing bolted angles or tabs to transfer beam shear forces to columns and complete joint penetration groove welds to join beam flanges to columns for moment-resistance (Figure 2). In 1972, Popov and Stephen published research validating the performance capability of these connections, and the welded unreinforced flange, bolted web (WUF-B) connection became the standard for steel moment frame and high-rise construction in the western U.S.

Though no structures of this type had yet experienced strong earthquakes, in the early 1960s, engineers placed language in the Uniform Building Code (UBC) requiring that all buildings, in excess of 13 stories or 160 feet in height, be provided with a moment-resisting steel frame capable of resisting at least 25% of the required seismic forces. In the building booms of the 1960s, 70s, and 80s, engineers designed hundreds of these structures in major west coast cities. In February 1971, downtown Los Angeles experienced moderate shaking from the San Fernando earthquake and engineers observed that the new high-rise buildings performed well. Downtown Los Angeles and San Francisco continued to see moderate shaking in a series of earthquakes in the 1980s, including the 1983 Coalinga, 1984 Morgan Hill, 1987 Whittier-Narrows, and 1989 Loma Prieta earthquakes. In each case, following cursory inspections, steel frame buildings mostly appeared undamaged, bolstering the profession’s confidence. A few fractures were discovered in some buildings, both in 1971 and 1989, but their significance was not understood nor was their presence disseminated. By 1988, most engineers believed they truly knew how to design earthquake-resistant structures and the Welded Steel Moment Frame (WSMF) structure was the gold standard for earthquake resistance. Although some engineers perceived problems with the now typical WUF-B connection, the 1988 UBC required the use of this detail in steel moment frames used for seismic resistance unless the engineer proved other connections would perform adequately, even including a “penalty factor” of 1.25 on the connection forces for other connections. This all changed on the morning of January 17, 1994.

Figure 3. The Southern California Automobile Association Building. To the right, a large permanent drift in the building.

One of the first discoveries of damage was at the Getty Art Museum, a WSMF structure then under construction in the hills between West Los Angeles and Sherman Oaks. Workers returning to the site observed strange cracks (fractures) in the still exposed steel moment connections. Then, an engineer performing a post-earthquake inspection of the Santa Clarita City Hall was surprised when a fractured bolt fell on his head when he opened a ceiling. Removal of fireproofing revealed similar cracking in that building’s connections. Engineers observed that the U.S. Borax Corporation headquarters building in Valencia and the nearby Southern California Automobile Association Building (Figure 3) had large, permanent interstory drift and found fractured connections in those buildings as well. Fracture patterns varied. In some cases, the fracture severed the welded bottom beam-flange-to-column-flange joint. In others, the fracture progressed into the column flange, forming a loose divot of column flange material. In a limited number of other cases, the fracture propagated into the column and across the column web (Figure 4). In some cases, bolted web connections also failed, shearing bolts or fracturing shear tabs.

Engineers rapidly lost faith in these structures and began performing detailed inspections of many building connections, using visual inspection and ultrasonic testing (UT). Visible connection fractures were found in more than 20 buildings and, in a few cases, more than half the connections were damaged. Potentially more concerning was that UT inspection revealed rejectable flaws, interpreted as incipient cracks, in many buildings (well over 100). An emergency code change removed the prescriptive WUF-B connection from the building code, substituting a requirement to demonstrate, by testing, that moment connection details could perform acceptably, effectively rendering WSMF construction impractical for new buildings. Los Angeles County then adopted a requirement for mandatory inspection of steel buildings within the zone of intense shaking.

Structural engineers desperately needed guidance on inspecting these structures, repairing damage, evaluating and upgrading undamaged buildings, and designing new buildings. The Structural Engineers Association of California (SEAOC), Applied Technology Council (ATC), and California Universities for Earthquake Engineering (CUREE) formed the SAC Joint Venture and entered into a cooperative agreement with the Federal Emergency Management Agency to conduct $12 million of field, laboratory, and analytical research into the problem. This research found that the connection fractures were the result of many factors, including an inherently flawed connection geometry; poor construction; poor welding technique, lack of adequate inspection; use of poorly controlled base and weld filler metals. Research revealed similar damage had occurred in steel buildings in the 1971 San Fernando, 1989 Loma Prieta, and 1993 Landers Big Bear earthquakes. In January 1995, the Kobe earthquake produced similar damage in Japanese steel buildings. The FEMA/SAC project concluded in 2000 with the publication of a series of guideline and research reports (FEMA 350, FEMA 351, FEMA 352, FEMA 353, FEMA 354 and FEMA 355). These publications resulted in massive changes to design practice, reflected in AISC 341, the introduction of a new steel material specification (ASTM A992), and new design specifications (AISC 358, AWS D1.8). Also, a far more measured approach was instituted for the introduction of new systems and requirements in the building code.

Many lessons were learned from the effort to respond to the damage to WSMF buildings in the Northridge earthquake that hopefully will result in much better performance in future large earthquakes. However, a larger lesson remains. Structural technology is continually changing and evolving with new code requirements, materials, detailing practices, and systems constantly being introduced. As a profession, we are more careful about the adoption of new approaches on a wide scale basis than we once were. As individuals, engineers must use new approaches with caution, think through the possible pitfalls, and proceed cautiously, lest the next earthquake teaches us unpleasant lessons about our practice.■

References

AISC, Specification for Structural Steel Buildings, AISC 360-16, 2016, American Institute of Steel Construction, Chicago, IL

AISC, Seismic Provisions for Structural Steel Buildings, AISC 341-16, 2016, American Institute of Steel Construction, Chicago, IL

AISC, Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications, AISC 358-16, 2016, American Institute of Steel Construction, Chicago, IL,

ASTM International, Standard Specification for Structural Steel Shapes, A992, 2015. American Society of Testing and Materials International, West Conshohocken, PA.

ASCE, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, ASCE/SEI 7-16, American Society of Civil Engineers, Reston, VA.

AWS, Structural Welding Code, Steel, D1.1, 2015, American Welding Society, Miami, FL.

AWS, Seismic Supplement, AWS D1.8, 2016, American Welding Society, Miami, FL

ASCE, Seismic Evaluation and Retrofit of Existing Buildings, ASCE 41-17, 2017, American Society of Civil Engineers

Popov, E.P. and Stephen, R.M., “Cyclic Loading of Full-Size Steel Connections,” American Iron and Steel Institute Bulletin No. 21, American Iron and Steel Institute, New York, NY, February 1972

SAC Joint Venture: Recommended Seismic Design Criteria for New Steel Moment-Frame Buildings, Report FEMA 350, June 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: Recommended Seismic Evaluation and Upgrade Criteria for Existing Welded Steel Moment-Frame Buildings, Report FEMA 351, June 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: Recommended Postearthquake Evaluation and Repair Criteria for Welded Steel Moment-Frame Buildings, Report FEMA 352, June 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: Recommended Specifications and Quality Assurance Guidelines for Steel Moment-Frame Construction for Seismic Applications, Report FEMA 353, June 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: A Policy Guide to Steel Moment-Frame Construction, Report FEMA 354, June 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: State of Art Report on Base Metals and Fracture, Report FEMA 355A, September 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: State of Art Report on Welding and Inspection, Report FEMA 355B, September 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: State of Art Report on Systems Performance of Steel Moment Frames Subject to Earthquake Ground Shaking, Report FEMA 355C, September 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: State of Art Report on Connection Performance, Report FEMA 355D, September 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: State of Art Report on Past Performance of Steel Moment-Frame Buildings in Earthquakes, Report FEMA 355E, September 2000, Federal Emergency Management Agency, Washington D.C.

SAC Joint Venture: State of Art Report on Performance Prediction and Evaluation of Steel Moment-Frame Buildings, Report FEMA 355F, September 2000, Federal Emergency Management Agency, Washington D.C.