An Investigation into Demolition of Complex Structures

Scarcity of buildable land, aging infrastructure, and changes in urban environments create an increasing demand for the demolition of existing structures. Often, demolition is planned and executed by a demolition contractor relying on experience and judgment for techniques and sequencing. Appropriate for some types of structures, such as small residential buildings with large offsets from surrounding structures, demolition plans not prepared by an engineer may not be appropriate for larger and more complex structures, where the consequences of unforeseen structural behavior during demolition can be dramatic or even fatal.

Just as the design of a complex structure requires careful consideration of structural engineering principles, the controlled demolition of a complex structure should include consideration of load paths, member capacities, the formation of structural mechanisms, and more. In fact, controlled demolition arguably requires an understanding of advanced structural engineering principles, such as non-linear geometric behavior and post-yield material behavior, due to the large displacements and high member demands inherent in many demolition techniques. This is particularly the case for demolition techniques where the structure is purposely weakened prior to demolition. The pre-weakened structure must remain stable for loads that are present before demolition to protect demolition workers, adjacent property, and the public. It is precisely for these reasons that a demolition plan prepared by an engineer, competent in the field of structural deconstruction and controlled demolition, is appropriate for the demolition of a complex structure.

When examining cases where a demolition plan is prepared by an engineer, the role of the engineer is different than that of an Engineer of Record (EOR) for traditional building design. Building codes provide clear guidance on design loads, safety factors, and a design or constructability review process for new construction; those codes provide little guidance for engineers planning a demolition. An EOR for new construction often limits his/her role to that of the completed structure and excludes intermediate states of the building as construction proceeds. By contrast, the engineer’s primary role in demolition is often to consider intermediate deconstructive states as original load paths change throughout the controlled demolition process. Further, design and construction of new structures involve new materials with well-known properties. A structure scheduled for demolition is typically at or near the end of its useful life, leading to issues of archaic materials, degradation, fatigue, undocumented modifications, and the lack of original structural plans for guidance.

Two more key distinctions between new construction and demolition are the relationship between the contractor and the engineer, and the checks-and-balances for their respective activities. Traditionally, in new construction, an EOR is hired to prepare the structural plans, and a contractor is hired to execute the plans. If the contractor wishes to deviate from the structural plans, a formal communication process is in place, such as a request for information (RFI). This process alerts the EOR of the requested deviation and ensures the EOR formerly reviews the request and either approves or denies the deviation. Both the engineering and construction phases include oversight, including plan check comments for the engineer’s work and special inspection for the contractor’s work. To the contrary, demolition contractors often hire the engineer. Due to limited regulations, communications are usually less formal, even for significant changes. Building officials may have limited expertise in demolition and provide little oversight. Finally, due to the rapid nature of many demolitions, there may be little time to consider the ramification of field changes to the demolition plan.

Engineer vs. Competent Person

OSHA requirements related to demolitions, intended to protect workers and not to regulate the role of an engineer, include provisions that specify an “engineering survey” by a “competent person” prior to demolition. The definition of a competent person in OSHA regulations (29 CFR 1926.32[f]) is:

…one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them…

In many cases, an experienced demolition contractor is likely to understand potential hazards far better than a design professional with limited demolition expertise. Further, the demolition contractor is typically in a contractual position to take prompt corrective measures via their control over demolition worker actions.

However, during the controlled demolition of a complex structure, the demolition sequence may result in local or global structural instabilities not apparent to a person unfamiliar with load path, changes in the load path, buckling, mechanism formation, and torsional instability. In those cases, an engineer familiar with the structure and the demolition plan is best capable of identifying hazards associated with structural instability during demolition. This is particularly true when pre-weakening structures prior to demolition, which is alluded to in the OSHA regulations (29 CFR 1926.859[g]):

…During demolition, continuing inspections by a competent person shall be made as the work progresses to detect hazards resulting from weakened or deteriorated floors, or walls, or loosened material. No employee shall be permitted to work where such hazards exist until they are corrected by shoring, bracing, or other effective means…

Unfortunately, even in cases of demolitions involving engineers, the engineer may not have “authorization to take prompt corrective measures to eliminate” hazards associated with instability. This may be because of the engineer’s contractual relationship with the demolition contractor, or because of the contractor’s traditional responsibility for means-and methods of construction. This can result in tragic consequences during demolition.

Case Study

A steel boiler structure at a power plant had reached the end of its useful life and was scheduled for demolition (Figure 1). The structure consisted of eight stories of steel columns and beams suspending a 3-million-pound boiler assembly. Steel diagonal braces in each story provided lateral support. Due to the weight and complexity of the boiler assembly, it was determined that the structure should first be toppled and the boiler disassembled from ground level. Proximity to operating power plant components ruled out explosive demolition. The demolition contractor hired an engineer (required by that jurisdiction) to develop a plan to pre-weaken the structure, followed by mechanical toppling.

Ten days before the incident, the engineer submitted a plan to the demolition contractor for a “three-hinged pull” design, involving the cutting of three “V” notches at selected first story columns and removal of selected first story diagonal braces. The weakened columns would then be collapsed using cables attached to them, resulting in the toppling of the remaining structure. A summary of the demolition plan is as follows:

- Removal of three of seven first story diagonal elements;

- V-notches cut near the top and bottom in three of the six first story wide-flange columns;

- Cut one notch near the middle of the aforementioned columns. Install H-shaped supports preventing middle notch closure, ensuring stability of the columns prior to toppling;

- Attach cables to the weakened columns at mid-height and extend the cables to a location clear of the fall zone; and,

- Remove the H-shaped notch supports and fail the weakened columns by pulling on the cables. This initiates toppling.

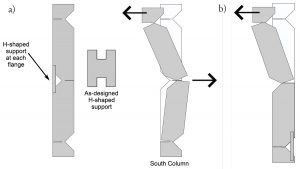

As implied by the demolition sequence, the configuration of the V-notches and installation of the H-shaped supports was critical to the stability of the weakened structure. As shown in Figure 2a a notched column with H-shaped support maintains its stability by preventing the closure of the middle notch. The top and bottom notches are kinematically restrained and cannot rotate without corresponding closure of the middle notch. Removal of the H-shaped support allows lateral force, applied at the column mid-height, to result in high bending stresses at the remaining steel around all three notches. The steel yields, allowing the open notches to rotate closed, initiating a collapse mechanism. Prior to toppling, the H-shaped supports are necessary to prevent global instability associated with changes in load path through the weakened/notched columns. Mass eccentricities are inherent in the structure from existing loads and applied loads such as environmental loads (e.g., wind) and forces induced by the demolition crew.

Shortly after receipt of the engineer’s plan, the demolition contractor began pre-weakening the structure. However, several field changes to the plan were made by the demolition contractor, including:

- The removal of two additional first story diagonal braces (i.e., 5 of 7 were now removed);

- The overcutting of notches in the columns beyond the dimensions specified by the engineer;

- In lieu of H-shaped supports, steel cut from the column notches was re-purposed as “wedge supports.”

- Installation of wedge supports at bottom notches rather than at mid-column notches.

According to the demolition contractor, removal of the extra braces and the overcut “V” notches were performed to ensure that the structure was weakened sufficiently to be toppled with the cables. Ironically, the decision to place the supports at the bottom notches of the columns was due to worker safety concerns. The original plan required workers to use a lift to place mid-column H-supports; the contractor felt workers using the lift could not quickly evacuate the fall zone in the event of a premature collapse. The contractor elected to make the final cut at the base of the column. The decision to reuse steel cut from the column notches as supports was apparently made for the sake of convenience.

The demolition contractor reported verbal approval for changes to the demolition plan from the engineer on the day of the demolition. However, no formal approval process was in place, and there is no evidence the engineer performed additional calculations in support of the changes. Regardless, the engineer was on-site during the day of the incident and admitted to observing the changes. According to the engineer, he recognized safety concerns associated with the changes and instructed the demolition contractor to stop work just prior to the incident. The engineer’s warning was not heeded.

The changes resulted in a weakened structure more vulnerable to premature collapse. However, moving the H-shaped/wedge supports to the bottom “V” notches significantly influenced the stability of the columns. As shown in Figure 2a, the placement of the H-shaped supports prevented rotation of the top and bottom notches. The configuration in Figure 2b is ineffective at preventing the middle and top notches from rotating closed and initiating the global collapse mechanism (regardless of the lower H-shaped support effectiveness). The modification from the original plan resulted in a global instability condition identifiable by simple engineering modeling, but not apparent to the demolition contractor.

Figure 2. a) As-designed: column stable until H-shaped support removal from mid-column notch; b) As-built: H-shaped support at lower column notch does not prevent closing of notches above.

As the demolition crew continued to perform their final cuts moments before planned toppling, the unstable columns collapsed and the entire structure fell. One worker was killed, and two others were injured.

Engineering a Safer Demolition

The construction industry in the U.S. has a long record of ever-increasing safety through worker education, procedural safeguards, codified design/construction practices, and oversight during the design/construction process. Engineers improve safety in new construction by anticipating possible loading conditions and designing the structure to behave in an acceptable manner subject to those conditions. There is broad acceptance of the need for this expertise in the construction of complex buildings.

The case study demonstrates demolition of a complex structure requires similar expertise to ensure the structure behaves in an acceptable manner subject to demolition loading conditions. Most demolitions do not result in injuries or fatalities, but there are opportunities for safety improvements in the demolition industry, including:

- Mandatory involvement of an engineer for the demolition of complex structures. A thorough understanding of structural engineering principles is key to identifying hazards associated with instability during demolition. For some structures and demolition techniques, engineering licensure should be one qualification of the “competent person.”

- More specific requirements for a demolition plan that address the following: What should be the qualifications of the preparer? If a building department lacks demolition expertise, who should review and approve the plan? What measures should a plan include to address the safety of surrounding structures and the public? Important questions such as these could prompt Statewide or nationwide consensus documents for demolitions.

- Design load and safety factor requirements for pre-weakened structures. As illustrated by the case study, pre-weakening can result in premature collapse, presenting an extreme hazard to demolition workers. Guidance for engineers considering design loads and safety factors for structures in a weakened state could be codified, similar to ASCE-37 for temporary structures.

- Demolition plan review and oversight by experienced individuals. Building departments that lack demolition expertise should seek it via peer review or third-party plan reviewers specifically competent in the decomposition of structures and controlled demolition processes. Proper oversight and the authority to stop work throughout the demolition process can significantly enhance safety.

- Clarification of the relationship between the engineer and demolition contractor. Both the engineer and the contractor play a key role in a safe demolition. Similar to new construction, communication between the two could be enhanced by a more formal process. A system of written requests for plan modifications by the contractor, prompting engineering evaluation and approval by the engineer, could help identify hazards associated with those modifications. Finally, the engineer’s on-site presence should be required during safety-critical phases of the demolition, as defined by the engineer in the demolition plan, and the engineer should have the authority to stop work upon hazard identification.▪

References

CBSC, 2013, California Building Code (CBC), California Code Regulations Title 24, Vol. 2, 2013 edition, pp 556,“Chapter 33 Safeguard During Construction, Subpart 3303 Demolition, Section 3303.1 Construction Documents”, page 556, California Building Standards Commission, Sacramento, California.

ICC, 2015, International Building Code, Structural Provisions, Vol 2, 2015 edition, pp 591 to 592, International Code Conference, Country Club Hills, Illinois

OSHA, Regulations Standard – 29 CFR, Part 1926 Safety and Health Regulation for Construction, Subpart “T,” Standard 1926.850, Demolition, Part No. 1926.850 Preparatory Operations, Occupational Safety and Health Organization, United States Department of Labor, Washington DC.

SFDBI, San Francisco Building Code – Administrative Bulletin 036, October 1993 (Updated 01-01-08 for code references), City of San Francisco Department of Building & Inspections, San Francisco, California.

LADBS, Information Bulletin / Public Building Code, P/BC 2014-039 Revised 05-11-16, Demolition of Buildings, The City of Los Angeles Department of Building and Safety, Los Angeles, California.

ASCE, ASCE 37-14 Design Loads on Structures During Construction, 2014, American Society of Civil Engineers, Washington DC.

OSHA, Regulations Standard – 29 CFR, Part 1926 Safety and Health Regulation for Construction, Subpart “C,” General Safety and Health Provisions, Standard 1926.32(f), “Competent Person,” Occupational Safety and Health Organization, United States Department of Labor, Washington DC.

OSHA, Regulations Standard – 29 CFR, Part 1926 Safety and Health Regulation for Construction, Subpart “T,” Standard 1926.859, Demolition, Part No. 1926.859 Mechanical Demolition, Occupational Safety and Health Organization, United States Department of Labor, Washington DC.

UFC, Structures to Resist the Effects of Accidental Explosions, Unified Facilities Criteria, UFC 3-340-02, December 2008, Department of the Defense, USA