Post-Disaster Observations of the Kahramanmaras Turkiye Earthquake Sequence — Part 1

On the morning of February 6, 2023, Turkiye awoke to the news of a destructive earthquake in the southeast of the country. Although the epicenter of the earthquake was estimated to be near the city of Kahramanmaraş, there was no proper news from many other cities in the region. While everyone was trying to grasp the extent of the event and its effects, a second devastating earthquake occurred in the nearby area. As the day progressed, the gravity of the situation began to emerge.

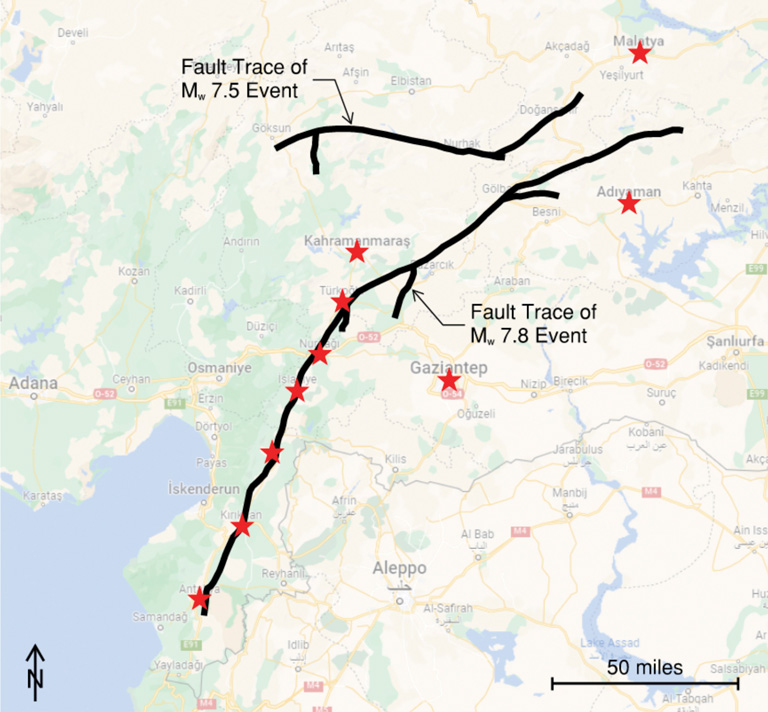

At 4:17 AM local time, a 7.8-magnitude earthquake occurred as a result of a complex fault rupture with a total length of about 250 miles. Nine hours after that, a second 7.5-magnitude earthquake was triggered, 60 miles north of the first one, with a total fault rupture of about 120 miles. This sequence of shallow earthquakes together with their numerous aftershocks caused widespread devastation, with the total number of fatalities exceeding 50,000 and more than 200,000 buildings collapsed or were heavily damaged over a vast region in southern and central Turkiye. Eleven provinces (Adana, Adıyaman, Diyarbakır, Elazığ, Gaziantep, Hatay, Kahramanmaraş, Kilis, Malatya, Osmaniye, and Şanlıurfa) were affected by these earthquakes with a total population of 14 million people. This corresponds to approximately 15% of the country’s population. It is estimated that more than 1.5 million people were left homeless. The financial burden of the earthquakes on the Turkish economy is estimated at $100 billion (US) which may amount to nearly 10% of GDP in 2023. Just the damage in housing units alone constitutes 55% of this burden.

Shortly after the earthquakes, the authors joined an extensive reconnaissance team organized by the American Concrete Institute (ACI) Disaster Reconnaissance Committee (Committee 133) and including representatives from American Society of Civil Engineers (ASCE), Structural Engineering Institute (SEI), the National Institute of Standards and Technology (NIST), and structural engineering faculty and students from numerous universities. This article is the first in a two-part series and presents a background on regional seismicity, seismic design and practice in Turkiye, and the authors’ observations from the field. The second article will discuss observations relevant to structural practice in the U.S.

Regional Seismicity and the Earthquake Sequence

Turkiye is located in one of the most seismically active regions in the world. The country is mostly located on the Anatolian block, which sits between three main tectonic plates, namely the Eurasian, African, and Arabian plates. Nearly 20 earthquakes of magnitude greater than 7.0 and 200 that are greater than 6.0 have struck Turkiye since 1900, meaning one major earthquake about every five years.

The Kahramanmaraş Earthquake Sequence occurred in the Eastern Anatolian Fault Zone. It is a 400-mile-long left-lateral strike-slip fault system where the Arabian plate is pushing the Anatolian block towards the northeast. This fault system is known to have produced damaging earthquakes over its various segments throughout history. However, a segment that is named the “Maraş seismic gap” was silent for at least 500 years. The first earthquake began on a smaller segment close to this seismic gap and, after “jumping” to the main fault, propagated bilaterally towards the northeast and southwest. Ten minutes later, a 6.7-magnitude aftershock occurred 6 miles west of the mainshock’s epicenter. This mainshock and the following aftershocks triggered the 7.5-magnitude earthquake on a splay fault of the East Anatolian Fault Zone nine hours later. All were shallow earthquakes having focal depths of 4-5 miles, which means that the massive amount of energy did not have time to dissipate before reaching the foundations of structures.

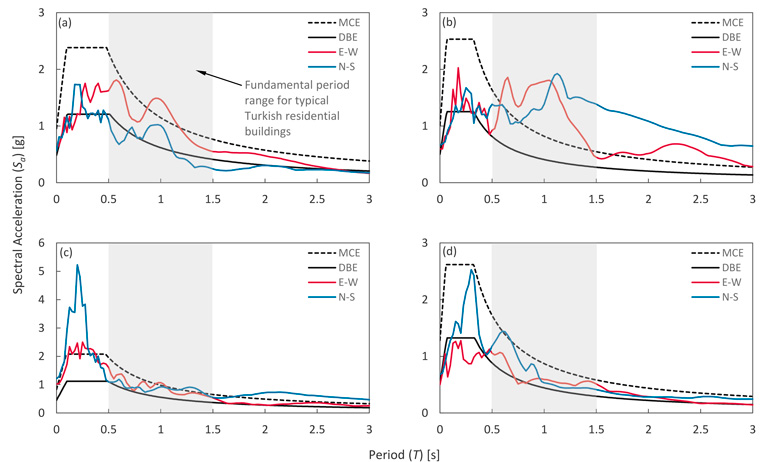

Fortunately for researchers, the Kahramanmaraş Earthquake Sequence was recorded by a dense network of ground motion stations located both along the East Anatolian Fault Zone and its vicinity. Very high horizontal and vertical peak ground acceleration (PGA) values were recorded during the 7.8-magnitude earthquake by the station closest to the epicenter (2.2g horizontal, 2.0g vertical). Several stations in Kahramanmaraş, Hatay, and Gaziantep recorded PGA values between 0.5g and 1.0g. The stations along the fault rupture also recorded extreme peak ground velocity (PGV) values (on the order of 40 in/s) which could be interpreted as an indicator of the damage potential. The recorded PGV values at these stations were 3 to 4 times greater than the predicted values given by the seismic hazard map of the Turkiye Building Earthquake Code. For the records close to the fault rupture, the design spectral accelerations are generally exceeded for a period range that corresponds to the typical residential buildings (0.5 to 1.5 seconds) in the region. These high demands posed a significant risk even for code-conforming residential buildings in some locations. Moreover, the cumulative effect of the successive aftershocks and the 7.5-magnitude earthquake increased the damage and led to more collapses. In various parts of the region, soil bearing failures and excessive settlements of the building foundations were also reported due to soil liquefaction. The ground motion records indicate soil amplification in cities located by rivers due to soft soil conditions. For instance, the observed spectral accelerations for Antakya, which is located by the Asi (Orontes) river, exceeded even the maximum considered earthquake level in the period range from 0.5 to 1.5 seconds (Figure 1).

Seismic Design and Construction Practices in Turkiye

The history of seismic design codes in Turkiye begins right after the 1939 7.8-magnitude Erzincan earthquake. This rudimentary code evolved into a then-contemporary seismic design code in 1975 after revisions made in 1944, 1949, 1953, 1962, and 1968. Partly influenced by the “Blue Book” of the Structural Engineers Association of California (SEAOC), the 1975 code mentioned ductility and base shear force explicitly for the first time. Calculation of the seismic forces based on an observed-intensity-based seismic zonation map, minimum cross-section dimensions, minimum reinforcement ratios, and the design of beam-column joints were among the improvements of the code. This code remained in effect for more than twenty years which corresponded to a time of rapid economic growth in Turkiye. Therefore, a considerable portion of the current building stock was constructed during that period. In 1998, the code was renewed following the developments in structural analysis and design procedures in the world. For the first time, it included nonlinear seismic analysis methods and a probability-based seismic zonation map. The aftermath of the devastating 1999 Gölcük and Düzce earthquakes (7.6-magnitude and 7.2-magnitude respectively) led to revisions in 2007 including procedures for the seismic assessment and retrofitting of existing buildings. A modern reinforced concrete design specification (TS 500) that mostly follows American Concrete Institute (ACI) 318 was also enacted in 2000, which requires the use of ready-mix concrete and deformed low-carbon steel rebars. Additionally, a building inspection law was enacted after observing a widespread code-conformance problem. The code took its current form in 2018. It is a state-of-the-art code that mainly resembles ASCE 7 for the design of new buildings. The code includes dedicated chapters for the seismic analysis and design of reinforced concrete, steel, prefabricated construction, masonry, and timber buildings as well as high-rise buildings, seismically isolated buildings, and foundations. The code is accompanied by a coordinate-based probabilistic seismic hazard map that gives the design spectra for the service level (43-year and 72-year return periods), design basis (475-year return period), and maximum considered (2,475-year return period) earthquakes.

Based on the developments in the seismic design codes and construction inspection, the building stock in Turkiye can roughly be classified as pre-2000 and post-2000. The pre-2000 buildings may be assumed as more vulnerable to earthquakes than the post-2000 buildings due to the inadequacy of the older seismic design codes, the lack of construction inspection, and poor material quality (e.g., plain rebars with low strength, hand-mixed concrete having 1-1.5 ksi compressive strength, etc.). Approximately half of the buildings in the region are known to have been built prior to 2000. However, poor seismic design and construction practices and the lack of proper inspection manifested themselves as severe damage, if not as collapse, in many post-2000 buildings as well. A construction boom in the region within the last 15 years resulted in a considerable number of approximately 10-story residential buildings, many of which were severely damaged or totally collapsed due to poor design and/or construction.

The typical residential building practice in the region consists of reinforced concrete moment frames infilled with unreinforced masonry (URM). The extensive use of URM in-fill and partitions creates significant nonstructural damage risk since these walls fail and fall apart at low drift levels (0.5 to 1.0% interstory drift ratios). The first stories of the buildings are typically open store-fronts set back from the upper floors which have overhangs as balconies or extended rooms (Figure 2). The typically greater height of the first story together with the partial or complete absence of the infill URM walls creates a potential soft/weak story. This issue appears to be infrequently addressed in the design practice, partially because the URM walls are often neglected in the structural design. The use of shear walls is mostly limited to the perimeter of the elevator shafts or adjacent to stairs if any shear walls are provided. Especially for the pre-2000 buildings, weak-column strong-beam cases could occur which may lead to “pancake-type” collapses during strong seismic events. Another common construction issue is the workmanship that results in poorly consolidated concrete, 90-degree (instead of 135-degree) hooks in stirrups, inadequate splice lengths, and weak confinement regions. These deficiencies are quite common in the pre-2000 buildings but the observations indicated that they are not limited to older buildings. Furthermore, the configuration of the structural system is often compromised to satisfy architectural demands. The most common configuration problems include irregular column lines, beams framing into other beams, absence of beams between the columns, and offsets between the centerlines of beams and columns.

In many recently constructed buildings, instead of regular slab-with-beam construction, the use of shallow beams between the columns with relatively thin slabs and one-way joists is common. The gap between the joists is typically filled with nonstructural elements such as bricks or styrofoam to obtain a flat ceiling. This construction type is preferred due to the reduced formwork cost and the architectural appeal of flat ceilings. However, it reduces the lateral stiffness of the building and increases diaphragm flexibility which are typically not accounted for during design. Although the 2018 Turkish Building Earthquake Code permits the use of this type of system if a minimum amount of shear wall is provided, observations from the field show that this requirement was violated in many new buildings.

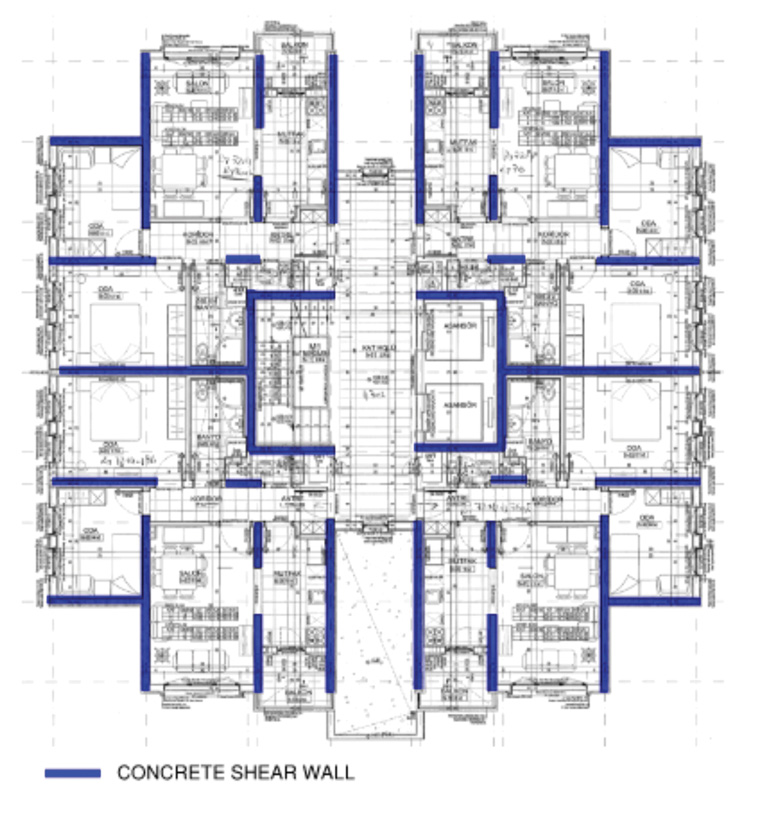

One less common building type in the region is the “tunnel form” which is mostly used for the social housing built by the government. The lateral force-resisting system of tunnel-form buildings consists of only shear walls, which are cast simultaneously with slabs using box-shaped formwork. Due to the high shear wall amount, this type of construction could be deemed less vulnerable to earthquakes (Figure 3). The shear wall detailing for tunnel form construction is the same as for shear wall buildings constructed in a conventional manner.

Other contributing factors to the poor seismic design are the lack of engineering licensure in Turkiye and the heavy reliance on all-in-one structural analysis and design software. Additionally, the enforcement of building regulations remains problematic in Turkiye. Although the building inspection law has been in effect for twenty years, strong relations between contractors and the government and possible corruption among the inspection firms and local authorities appear to still exist. In 2018, a construction amnesty was declared by the government to register illegal buildings, most of which disregarded the building regulations. In the hardest-hit cities, over 300,000 buildings benefited from this amnesty as of 2021.

Observations from the Field

Over a week-and-a-half period in late March and early April, the reconnaissance team observed buildings in the earthquake-affected region. Locations included Adıyaman, Antakya, Gaziantep, Hassa, Islahiye, Kahramanmaraş, Kırıkhan, Malatya, Nurdağı, and Türkoğlu (Figure 4). Buildings were chosen based on ease of access and ranged from functional to severely damaged. The team did not study many collapses, especially as debris removal had already begun. Almost all the buildings were concrete-framed, as described above, though occasionally with wood- or steel-framed roofs. The vast majority of buildings observed were built after 2008.

Types of structural damage observed included the following:

- Longitudinal bar buckling and/or fracture of moment frame column and shear wall vertical bars, especially at locations of poor ties (due to 90-degree hooks) or inadequate ties (large spacing, either due to design or construction practices) (Figure 5). In particular, a lack of ties extending into the foundations, leading to bar buckling at the foundation, was observed in many locations.

- Longitudinal bar buckling and/or fracture in moment frame beam horizontal bars, especially just beyond lap splices or where a portion of the longitudinal bars terminated (Figure 6). This damage was also observed where beams framed into the ends of shear walls in the strong direction.

- Shear failures in moment frame columns or in shear walls, especially due to inadequate ties or in shear walls with horizontal bars that were not restrained (Figure 7).

- Shear failure in moment frame beams and in moment frame beam/column joints (Figure 8).

- Tie fracture in columns or shear wall boundary elements (Figure 9).

- Residual drift, typically occurring in buildings with soft/weak stories (Figure 10).

- Pounding, occasionally at adjacent buildings but more frequently at buildings with a minimal construction joint between building sections (Figure 11).

Tunnel-form construction performance following the Kahramanmaraş Earthquake Sequence varied. Tunnel-form buildings in parts of Karacasu (six stories) and Antakya (eight stories) were undamaged and occupied or the occupants were planning for reoccupancy. However, in Kahramanmaras, the authors observed one 15-story tunnel-form building that had collapsed with several nearly identical tunnel-form buildings in the neighborhood severely damaged but standing. The shear wall damage and bar buckling observed in standard concrete buildings also occurred in the tunnel-form construction.

A few items of damage were directly attributable to poor construction practices. Poor concrete consolidation was more frequently observed than in U.S. buildings of similar vintage and led to shear failures or longitudinal bar buckling in shear walls (Figure 12). Column ties were observed bunched up in one area, leading to large gaps above/below the bunched area, which then led to longitudinal bar buckling. Ninety-degree hooks in lieu of the code-prescribed 135-degree hooks were also observed. In several instances, mechanical ducts and conduit were routed through shear walls that were relatively short in plan, leading to shear failure through the hole.

Buildings with short, or captive, columns were rarely observed in post-2000 reinforced concrete buildings the authors generally surveyed.

Both successful and unsuccessful nonstructural performance was observed. The primary nonstructural damage of note was to unreinforced masonry (URM) infill walls (Figure 13). Not only were the failures a major safety hazard but their damage was also a major obstacle to reoccupancy. Stairs were the other major nonstructural component which were often damaged. The vast majority of stairs consist of cast-in-place concrete without gaps/drift accommodation at the attachment to the floors. Longitudinal bar buckling and/or fracture along with concrete spalling were observed at many stairs where they connected to the main floor. The damage observed to stairs is also concerning as they are the primary, if not sole, exit path for building occupants. Many were rendered unsafe. Nonstructural damage was also observed to water tanks, ceiling grids, overhangs and canopies, and clay roof tiles. Very little to no damage was observed to gas tanks, generators, and mechanical equipment located at grade.

Conclusion

While the Kahramanmaraş Earthquake Sequence could not have been predicted, the destruction and loss of life were, unfortunately, not entirely unpredictable. Seismic hazard research indicated a “seismic gap” in large magnitude earthquakes along the fault system which ultimately ruptured in the Kahramanmaraş Earthquake Sequence. Issues in design, construction, inspection, and enforcement in Turkiye had been previously identified. All of this combined to affect the seismic performance of the primarily reinforced concrete buildings in the region.

Acknowledgments

The authors would like to extend their thanks to the leadership of Santiago Pujol, Cemalettin Dönmez, and Ayhan Irfanoğlu of the ACI Committee 133 team with whom the authors traveled. The authors would also like to thank the extensive list of faculty and students from the Izmir Institute of Technology, Middle East Technical University, Hacettepe University, Harran University, Eskişehir Osmangazi University, University of Canterbury, University of Nebraska-Lincoln, University of Kansas, The National Autonomous University of Mexico, and University of Belgrade who provided essential and exceptional in-field support.■