Is the Process Compromising the Service Life of Encapsulated PT?

Unbonded post-tensioned (PT) concrete slab construction is commonly used for many types of structures, from high-rise towers to low-rise concrete podiums and parking structures. Since the adoption of ACI 318-14, Building Code Requirements for Structural Concrete and Commentary, many jurisdictions now require fully encapsulated PT tendons for building applications in all environments to prevent moisture intrusion and improve durability. The effectiveness of full encapsulation, however, can be highly dependent on the PT system installation, specifically the cutting of the tendon tails. This operation may not be done with enough precision and care to protect the grease caps, which encapsulate the tendon tails and complete the PT system’s continuous moisture barriers.

Across several projects in the San Francisco Bay Area, the authors have observed a large number of opened PT stressing end pockets with a variety of installation defects, all leading to incomplete encapsulation of the PT tendon and making the PT system vulnerable to future corrosion. All of the observed defects were related to the installation of the PT system. Of those observed deficiencies, most were related to the improper cutting of the PT tendon tail.

A review of articles and papers on installation issues with encapsulated PT systems, and discussion with engineers outside of California, indicate that these problems are occurring not only in the San Francisco area but all over the country.

Background

ACI 423.7-14, Specification for Unbonded Single-Strand Tendon Materials, requires the use of encapsulated tendons for all applications governed by ACI 318 (such as elevated slabs and beams). Previous versions of the document required encapsulation only in aggressive environments. Since ACI 423.7-14 is now referenced by ACI 318-14, the use of encapsulated tendons is required by code in many states and jurisdictions.

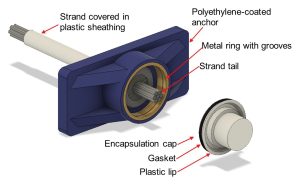

At the stressed end of the tendon, the two main elements of the encapsulation system are the polyethylene-coated anchor and a plastic encapsulation cap (herein referred to as the “grease cap”) that is placed on the strand tail after it has been cut to the proper length (Figure 1). The grease cap must fit snuggly in the metal ring of the anchor because this seal provides the watertight connection.

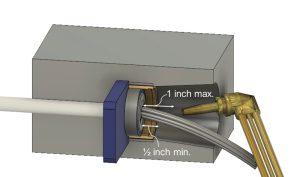

There are generally four techniques to cut tendon tails: an oxyacetylene torch, abrasive wheel, hydraulic shears, and gas plasma cutters. In the authors’ experiences, the use of an oxyacetylene torch (herein referred to as “torch”) is the typical method used at most construction sites unless another method is specified by the engineer-of-record in the contract documents (Figure 2). No industry standard currently specifies which cutting methods should be used.

However, the geometry of the small formed stressing pocket limits the positioning of the torch and torch visibility of the tendon and the stressing end anchorage by the operator. This increases the potential for damage to the stressing end anchorage and the tendon tail not being cut to the appropriate length (Figure 3). Proper tail lengths are addressed in the Post Tensioning Institute’s manual – PTI M10.3-16, Field Procedures Manual for Unbonded Single Strand Tendons.

Field Observations

The authors observed over 800 opened stressing pockets across two San Francisco Bay Area buildings with PT concrete slabs. The observed opened pockets comprised a large majority of the total number of stressing pockets in each building. All of the structures observed were built after the adoption of the 2016 California Building Code, which adopted ACI 318-14 and therefore required encapsulation of the PT tendons. In each case, the tendon tails were reportedly cut using torches. Of the more than 800 pockets observed, over 50% exhibited one or more of the conditions described below that could compromise the tendon encapsulation.

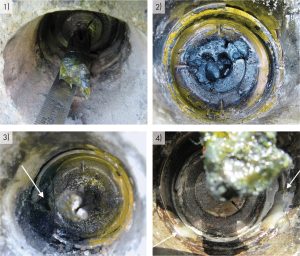

The conditions observed at these stressing end anchors can be generally grouped into the following categories. Figure 4 shows an example of each category.

- Tendon tail too long: If the tendon tail is not cut short enough, the grease cap cannot be fully seated and provide the required seal. Frequently this results in the tail also puncturing the grease cap, promoting moisture ingress. This condition was observed at more than one-third of the opened stressing pockets.

- Tendon tail too short: If the tendon tail is cut too short, the tendon tail may not puncture the temporary plastic seal holding the grease inside the grease cap.

- Molten and deformed anchorage ring: Prolonged and elevated temperature exposure to the torch flame within the confined space of the formed stressing pocket melted or deformed the anchor ring and prevented the proper seating of the grease cap.

- Debris in anchor ring: Debris in the metal ring, whether molten metal or plastic, impedes the seating of the grease cap. Often this debris can be from the cutting operation, and the condition may coincide with Category 3.

All four of these categories can reasonably be attributed to the difficulty of positioning a torch inside the small, formed stressing pocket and the limited visibility of the anchorage components during the cutting operation.

Recommendations

Based on field observation of opened stressing pockets in several existing recently constructed elevated concrete slabs in the San Francisco Bay Area, the authors observed defects that have compromised the encapsulated PT system. This would make the encapsulated system vulnerable to moisture ingress and future deterioration. Many of these defects can be attributed to using an oxyacetylene torch to cut the tendon tails and the constrained geometry of the formed stressing pocket. Several practices could be implemented in both the design and construction of the encapsulated PT systems to reduce the likelihood of these installation defects discussed above.

- Specify tendon tail-cutting methods that do not include the use of an oxyacetylene torch in the construction documents. Alternatives include hydraulic shears or plasma cutters.

- Ensure that qualified inspectors observe the stressing anchorages before and after the installation of the grease caps and confirm that nothing is impeding a good seal and full encapsulation.

- Provide adequate work platforms that allow individuals to be in a good working position to cut the tendon tails. For example, provide a platform where an individual can stand upright while cutting the tendon tail rather than leaning over the edge of the slab to cut the tendon tail.

In addition, PT anchorage manufacturers could assist in achieving and promoting best practices for the installation of encapsulated PT systems in some of the following ways:

- Discouraging the use of oxyacetylene torches to cut PT tendon tails for their products.

- Develop tendon tail encapsulation alternatives that are less likely to be compromised by typical construction practices.

- Provide repair options and procedures for typical damage to encapsulated PT systems.

- Actively participate in professional organizations to help develop standards for inspecting, installing, and repairing encapsulated PT systems.■