A Supertall Hybrid Timber Response to the Climate Crisis

Sustainably harvested mass timber significantly reduces embodied carbon. And yet it remains a niche technology in the global construction industry. Given the rather urgent timeline of the climate crisis, how can we make mass timber mass-market…and fast?

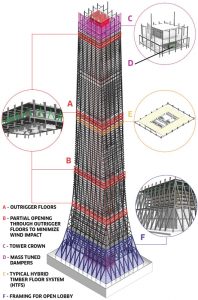

In response to this challenge, an interdisciplinary team of engineers and architects at DIALOG designed a 105-story supertall Hybrid Timber Tower (HTT) prototype that features a patent-pending, prefabricated, composite Hybrid Timber Floor System (HTFS). Designed as a series of building types stacked one atop the other (commercial, office, residential, and hotel), the HTT shows it is possible, technically and economically, to incorporate significant quantities of mass timber into any building type – irrespective of size or function – using a hybrid floor system.

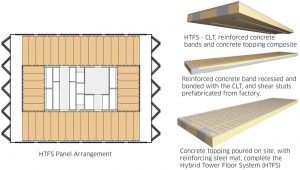

Without a doubt, floor systems in buildings represent the most significant opportunity for mass timber. A life cycle analysis showed that floor systems contribute as much as 73 percent of the environmental impact of a high-rise building’s structure. However, Cross-Laminated Timber (CLT) panels are currently restricted to about 26 feet due to strength and vibration issues. This restriction makes it challenging to deliver the long, column-free floor spans required for Class-A office commercial space and represents a significant barrier to mass-market acceptance.

The DIALOG team designed the HTFS to overcome this limitation. The composite system leverages the structural properties of concrete and steel to reinforce the engineered wood; post-tensioning cables and steel cages are encased in a concrete band and recessed into a CLT panel, allowing for the greater column-free spans of up to 40 feet. In addition, the HTFS is designed to improve fire safety; exposed wood chars to form a protective layer while the non-combustible concrete and steel band continues to support the panel (leaving the wood exposed reduces costs and offers the biophilic appeal of timber). Finally, an analysis by Canadian construction firm EllisDon shows the HTFS is cost-competitive with conventional all-concrete or hybrid-steel and concrete structures. At the same time, prefabrication allows competitive floor cycles in tall building construction.

The DIALOG team designed a supertall prototype to put the floor system into practice, leveraging a hybrid approach for the structure. A survey by the Council on Tall Buildings and Urban Habitat showed 79 percent of buildings 10 stories or less were all-timber versus just 33 percent of those above 10 stories; a hybrid approach makes more sense for taller buildings. The HTT structure comprises a concrete core with an external steel diagrid, wide at the base and narrow at the top, and designed to mimic a tree’s shape. The core is tied to the diagrid through outrigger trusses at each mechanical floor. RWDI’s collaborative partnership for wind studies confirmed that openings on some of the mechanical floors for wind bypass help break up wind turbulence. They also recommended placing a tuned mass damper at the top of the structure to reduce wind-induced building acceleration.

The design team incorporated the HTFS into the tower prototype to reduce structural embodied carbon by 46% versus a conventional floor system. The HTT incorporates 1,294,247 cubic feet of mass timber, 14 times more than the current tallest wood building, Mjøstårnet, in Norway. According to a 21-study review, mass timber sequesters an average of 119 pounds of carbon-dioxide equivalent emissions for each cubic foot of wood product, so the HTT locks up a significant amount of carbon.

The HTT prototype was awarded Fast Company’s 2021 World Changing Idea in Architecture, yet the HTFS is more incremental than radical in terms of structural innovation; it is based on existing, proven structural engineering concepts. The HTFS design has gone through multiple internal peer reviews and independent external peer reviews. In addition, the team has received Investments in Forest Industry Transformation (IFIT) and Green Construction through Wood (GCWood) grants. Both grants are through the National Research Council Canada for testing that includes but is not limited to full-scale structural strength testing, long-term creep, deflection, vibration, and small-scale fire testing. The team is confident the design will stand the rigors of testing and offer a new tool for architects and engineers looking to reduce the impact of their buildings.

Structural engineers have a vast opportunity to help address the climate crisis. According to The Institution of Structural Engineers, the embodied carbon of building materials represents 11% of global emissions, and a building’s structure can represent the majority of its embodied carbon. It is conceivable that halving embodied carbon in our building structures (recall the 46% reduction in the HTT) could have a more significant impact than if everyone on the planet stopped flying.

That is a massive impact. And if we all work together, we can achieve it. So, let’s get going.■

References

Lankhorst, G. et al. (2019). Life Cycle Analysis: Load-Bearing Structures of High-Rise Buildings in Western Europe. CTBUH Journal 2019 Issue II: 28-35.

Council on Tall Buildings and Urban Habitat (2017). Tall Buildings in Numbers. Tall Timber: A Global Audit. CTBUH Journal 2017 Issue II: 47-49.

Abrahamsen, R. (2017). Mjøstårnet – Construction of an 81 m tall timber building. 23. Internationales Holzbau-Forum IHF 2017.

Sathre, R. and O’Connor, J. (2008). Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environmental Science & Policy. 13(2): 104-114.

Toussaint, Kristin (2021). This 105-story skyscraper takes wood construction to new heights (with zero-carbon footprint). Fast Company, May 4, 2021. https://bit.ly/3889Ixt. Accessed Jan 27, 2022.

Global Alliance for Buildings and Construction, International Energy Agency and the United Nations Environment Programme (2019): 2019 global status report for buildings and construction: Towards a zero-emission, efficient and resilient buildings, and construction sector.

The Institution of Structural Engineers, Carbon: embodied and operational. https://bit.ly/3LQ0d4q. Accessed Jan 27, 2022.

Graver, B. et al. (2019) 2019 CO2 emissions from commercial aviation, 2018. International Council on Clean Transportation. Working Paper 2019-16.