Can you identify cold-formed steel thickness just by the feel of the stud? If you cannot, you are not alone. There are many ways to easily identify CFS thicknesses, including using materials you just might have in your pocket.

Learn How to Read the Printed Code

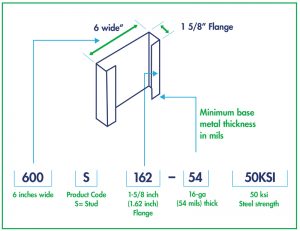

It is required for metal stud manufacturers to stamp the stud size and gauge on each product. If you are not sure how to read the printed code, here is an example from Clark Dietrich, a cold-formed steel manufacturer: 6-inch, 16-gauge studs are labeled CD600S162-54 50 KSI (Figure 1).

This stamp example means the stud has the following dimensions:

- 6 inches wide

- 1.62-inch flange

- 16-gauge (54 mils) thick

- Steel strength is 50 KSI

Note: A mil is equal to one-thousandth of an inch or 0.001 inch. This measurement is a typical manufacturing dimension used to specify the thickness of a product.

Consider the Colors

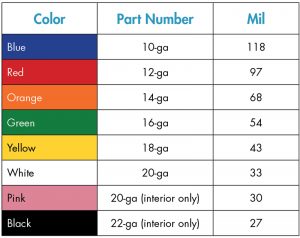

The ends of steel studs and tracks are painted with color markings to indicate their thickness, which means you can keep a color guide handy for a quick reference (Figure 2). Here is the rundown:

- Blue – 118 mils (10-gauge)

- Red – 97 mils (12-gauge)

- Orange – 68 mils (14-gauge)

- Green – 54 mils (16-gauge)

- Yellow – 43 mils (18-gauge)

- White – 33 mils (20-gauge)

- Pink – 30 mils (20-gauge; interior only)

- Black – 27 mils (22-gauge; interior only)

You may be wondering why two studs would be different for the same thickness, as demonstrated by the white and pink color markings. This is because interior framing often has less galvanizing than exterior members. Therefore, interior-grade members should not be used in exterior walls.

Use a Micrometer to Measure Material Thickness

If you cannot see any identifying marks, use a micrometer, a tool designed to make exact measurements within one-thousandth of an inch. Even though there are inside and outside micrometers available, it is recommended that you choose a C-shaped outside micrometer, which is easier to use with the rounded, sheared edges of cold-formed steel. Also, try measuring the knockout in the stud web rather than at the rounded edges at the lip.

Consult Online Gauge Guides

There are several metal thickness instrument gauge guides available online. It is important to point out that most are designed to measure sheet metal thicknesses and not cold-formed structural steel, but they can still be helpful. According to BuildSteel, “since a wide variety of CFS member profiles, depths, widths, and material thicknesses exist, the steel framing manufacturing industry developed a standard designator system that all CFS manufacturers and suppliers use. It is important to note that this universal designator system is used in identifying cold-formed steel framing in building codes as well.”

You can probably obtain enough information from these guides to make a relatively accurate estimate of cold-formed steel thickness.

Use Materials You Have on Hand – Or in Your Pocket!

If you are stuck, just reach into your pocket for some handy common-thickness reference materials (Figure 3).

- A quarter = 0.069” thick (approx. 14-gauge)

- A dime = 0.053” thick (approx. 16-gauge)

- Dollar bill = 0.0043” thick. Fold it to get 10 plies, and you have 0.043” (approx. 18-gauge)

It is also helpful to know the most common cold-formed metal framing sizes and shapes. You do not have to memorize this list, but the Table shows a quick overview.

At the end of the day, learning how to read the printed code is one of your best options. But the good news is that there is more than one way to identify cold-formed steel thicknesses while you are in the field, especially if there are no visible marks on the studs.■