The use of masonry began with unreinforced dry-stack (mortarless) construction. For millennia, stone has been laid dry without mortar. The Great Pyramid of Giza (c. 2600 BC) is an example of limestone and granite ground smooth and fits tight without mortar (Figure 1). There are numerous examples of residences, walls, fortresses, and towers constructed using dry-stack masonry throughout the world. Unreinforced, these structures rely on gravity and friction to maintain their stability.

The fascination with dry-stack masonry continues today. While stone retaining walls are popular, the emphasis in North America is now primarily on manufactured masonry units. In addition to building applications, dry-stack masonry for structures has been applied to segmental retaining walls using gravity or mechanically stabilized earth techniques.

Internationally, dry-stack construction is being used in modern residential and commercial construction. There are several features common to many contemporary dry-stack concrete masonry systems, including:

- Most use a form of grouted reinforcement with proprietary unit configurations that interlock and have aligning cores to accommodate the grout.

- Prestressing may or may not be grouted in place.

- Their use is often justified based on successful performance, experience, and available research.

In the United States, dry-stack masonry has been in our building codes for decades. However, it utilizes a surface bonding coating on both sides of the wall to provide structural flexural capacity. The current International Building Code (IBC), Section 2114 Dry-Stack Masonry, is based upon Allowable Stress Design procedures in Chapter 8 of TMS 402, Building Code Requirements of Masonry Structures. The materials and construction are based upon ASTM C946 – 18 Standard Practice for Construction of Dry-Stacked, Surface-Bonded Walls.

Based on new research, The Masonry Society (TMS) has developed a guide to update the design and construction methodology for dry-stack concrete masonry unit (CMU) walls. TMS 1430-21, Design and Construction Guidelines for Dry-Stack Concrete Masonry, is a non-mandatory aid for designers, building officials, contractors, educators, and others interested in dry-stack masonry construction. The guide is expected to be a precursor for inclusion in a future edition of TMS 402.

Systems

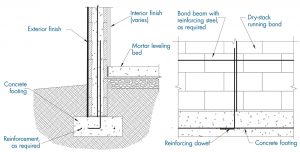

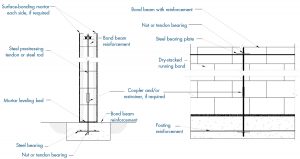

The guide addresses two specific systems of dry-stack (Figures 2 through 5). The units are always laid in a running bond (when units are placed with head joints horizontally offset at least one-quarter of the unit length in each course, as seen in Figure 2). The guide does not address other types of dry-stack masonry.

The differences between those in the guide compared to the methodology in the IBC includes:

- Unreinforced, surface-bonded masonry is not addressed.

- A surface-bonded coating can be used with reinforced CMU as an exterior finish (Figure 2), but it cannot be considered as providing any structural capacity. Only the grouted reinforcement provides flexural strength.

- A surface-bonded coating can also be used as an exterior finish with prestressed CMU (Figures 4 and 5). However, if the coating is applied to both faces of the CMU and the wall prestressing is designed to keep the wall in compression, the coating can be designed to provide increased in-plane shear capacity.

Design

Most engineers are familiar with reinforced masonry design using TMS 402. The procedures of the guide for dry-stack are similar, as shown below.

For mortared masonry, the design is based upon f´m, the net area compressive strength of the masonry system. It can be obtained by testing masonry prisms or conservatively determined by the Unit Strength Method shown in Table 2 taken from TMS 602, Specifications for Masonry Structures (courtesy of The Masonry Society). For the Unit Strength method, f´m is derived from the net area compressive strength of the units and the mortar type.

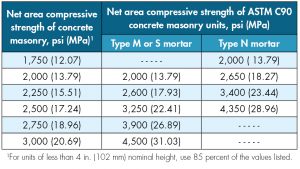

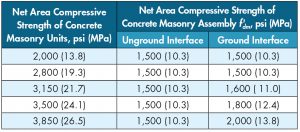

For dry-stack masonry, the design is based upon f´dm, the net area compressive strength of the concrete masonry assembly, as shown in Table 2.6-1 from the guide.

Notice the distinct differences in this table. First, there is no mortar since it is a dry-stack. Second, the f´dm is based upon the interface between units, either unground or ground. Research has shown that the bedding surface of a manufactured CMU that meets ASTM C90 standards is irregular such that when the dry-laid units are stacked and loaded in compression, the interface undergoes some micro-crushing that limits the assembly strength to 1,500 psi. However, if the bedded surfaces of the units are ground smooth, f´dm increases with the increased unit strength. (The guide also uses a lower strength reduction factor, φ, for designs using unground units.) Before using the ground interface values, it is best to check with local manufacturers to verify that they can produce ground units.

The guide is based upon Strength Design provisions (Chapter 9) and Prestressed Masonry provisions (Chapter 10) from TMS 402. However, engineers can use ASD provisions from Chapter 8.

Commonly Asked Questions

- How do you level the bottom of the wall if the concrete foundation is not perfectly level?

a. The first course is set in mortar for leveling.

- Will the courses remain level, and what are the tolerances?

a. If bedding courses become unequal, shims or mortar are used for correction.

- Do dry-stack walls require movement joints?

a. Rarely, since the units can shift slightly. However, joints should be used for fully-grouted walls and to protect coatings or finishes from random cracking.

- Can joint reinforcement or bond beams be used in the design?

a. No for joint reinforcement since the courses are not mortared. However, reinforced bond beams can be used since they are grouted.

- Can dry-stack walls be designed using stack bonded construction?

a. No, the guide only recommends running bond construction.

- Won’t the grout leak out the joints without any mortar?

a. Yes, while this is not detrimental to the system’s performance, it can be an aesthetic concern if the wall is exposed in service. In addition, extra care may be warranted if the walls are partially grouted, particularly if the ungrouted cells are to be filled with another material, such as insulation.

- Can an adhesive be used in the joints to level and provide an air seal?

a. The guide does not address this specifically, but the adhesive could be part of a proprietary system.

- Are cleanouts required?

a. No, since no mortar was used.

- Won’t the prestressing forces crack the CMU if there is no mortar in the joints?

a. Not if the units are bedded without “hard spots.” The prestressed method is particularly appropriate for using ground units to assure smooth bearing.

- Why can’t a surface bonded coating increase the wall strength for reinforced dry-stack walls, yet it can for prestressed walls?

a. The surface-bonded coating is only effective if it does not crack. Unfortunately, cracking is inherent in the design of reinforced walls. However, prestressed walls can be designed to avoid flexural tension.

- Can dry-stack masonry systems be used anywhere?

a. Since dry-stack design and construction using the guide is not yet code approved, users need to consider one of the following alternatives:- i. Considering dry-stack CMU as a special system under IBC Section 104.10 – Modifications and IBC Section 104.11 – Alternative materials, design, and methods of construction and equipment.

- ii. Having the system reviewed for code compliance using an established evaluation service, such as the International Code Council Evaluation Services (ICC-ES).

- Since dry-stack CMU is not a listed system in ASCE 7, what seismic design coefficients and factors (e.g., R, Cd, and Ώ0) are recommended?

a. For reinforced walls constructed with ground units, the recommendation is to use the comparable system values for mortared systems in ASCE 7. Otherwise, downgrade the system by one level and use those values.

b. For prestressed walls with a surface-bonded coating designed structurally, use the comparable system values for mortared systems in ASCE 7. Otherwise, use the values for unreinforced masonry.

c. These recommendations are expected to change as additional research into dry-stack is completed.

- What research is behind dry-stack masonry?

a. Research has been done internationally, but more recent U.S. research was performed at Clemson University and NCMA.

- Does the guide apply to the use of proprietary units as well as generic ones?

a. Yes, provided the proprietary units meet ASTM C90 standards.

- When used with prestressed dry-stack CMU, does the surface-bonded coating require a proprietary mix?

a. No, but it must meet the requirements of ASTM C887, Standard Specification for Packaged, Dry, Combined Materials for Surface Bonding Mortar, and be installed per ASTM C946.

- Is dry-stack masonry expected to replace mortared systems?

a. No, but there are situations where the system offers some economic savings without sacrificing performance.

- Will these systems require masons to build?

a. Yes, mason craftsmanship and understanding techniques are still essential.

- Can dry-stack walls be deconstructed and rebuilt elsewhere?

a. That is an option.

- Does dry-stack CMU provide fire resistance?

a. The guide outlines possible tests that could be performed to determine if a rating is possible.

- Can dry-stack CMU be used with a cavity wall and anchored veneer?

a. Yes; however, without using grouting, the anchors must be selected to attach to the face shells of the CMU.

- How do you attach anchor bolts or expansion bolts to dry-stack CMU?

a. Either grout the cores at anchor locations or check the capacity of the face shells.

- Does the guide offer design examples?

a. Yes.■

TMS 1430-21, Design and Construction Guidelines for Dry-Stack Concrete Masonry is available through The Masonry Society (https://masonrysociety.org).