Are We Testing for Flow Properties Correctly?

The rheological (flow) properties of concrete are essential for the construction industry, because concrete, for different elements of a structure, is placed into the formwork while it is in its plastic state. The flow properties affect not only proper concrete placement, consolidation, and finishing but also the hardened state properties such as strength and durability. Concrete that is not correctly placed and consolidated may have defects, such as voids and honeycombing, and be prone to aggregate segregation. Improper placement and consolidation may result in reduced compressive strength and increased permeability, reducing the concrete’s durability and sustainability.

Unfortunately, due to the complex composition of concrete, a decisive method to predict the flow of concrete is not yet available. The most commonly used workability test methods are based on empirical methodologies, such as slump tests. It is important to note that, at the same slump value, two concretes may exhibit different workability. However, numerous two-point tests have been developed over the years to measure both yield stress and plastic viscosity. The selection of a proper test and interpretation of the obtained results to predict the performance of concrete in the field are not that easy. The American Concrete Institute’s Report on Measurements of Workability and Rheology of Fresh Concrete (ACI 238.1 R-08) provides discussion and guidance.

Test Methods

Several test procedures for determining workability have been developed in the past for research, mixture proportioning, and field use. However, only the slump test is widely accepted and prescribed in codes and standards because of its ease of use. Even with the increased knowledge of concrete rheology and the development of several other test methods since the 1920s, the concrete industry is not yet convinced to replace the slump test.

ACI 238.1 R-08 describes 69 test methods that could be used to measure the workability of concrete, including the details of these test methods, their advantages, and drawbacks. Most test methods for workability can be classified as single-point and two-point tests. For example, slump test, penetrating rod (Kelly ball, Vicat, and Wigmore test), and K-slump test are used to measure the yield stress of concrete. In contrast, Vee-Bee consistometer test, LCL apparatus, flow cone test, and Orimet apparatus are used to measure the plastic viscosity of concrete.

Why Slump Test is Not Adequate

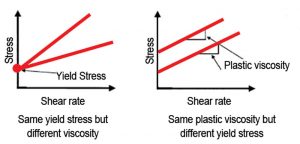

The slump test was developed in the early 1920s when concrete researchers recognized the role of water-cement ratio in concrete strength. The slump test was quickly adopted because of its simplicity. Using the slump test to assess the workability of fresh concrete has become questionable, especially for modern concrete mixtures incorporating chemical admixtures. Its primary deficiency is that two fresh concrete mixtures having the same slump value may behave quite differently at the job site (Figure 1). This is because the standard slump test is related only to the yield stress, and a single parameter alone cannot fully evaluate concrete flow characteristics. Even self-consolidating concrete (SCC), which is governed by the property of flowing under its own weight, is typically classified based on the results of empirical tests such as slump flow, V-funnel, L-box, and J-ring tests.

Figure 1. Drawback of slump test-predicted workability based on concrete rheology.

Reprinted with permission from ACI.

Concrete as a Bingham Fluid

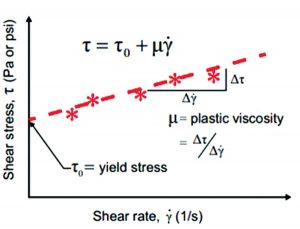

Research has now established concrete as a Bingham fluid. Based on this, the flow of concrete is better measured in terms of shear stress and shear rate. Many of the new methods recently developed have attempted to measure both yield stress and plastic viscosity (Figure 2).

Measurement of the rheological parameters of concrete is not easy to perform, as concrete has a broad range of particle sizes (from 1 μm cement grains to 10-20 mm coarse aggregates in normal concrete or even 100 mm size of coarse aggregates used in dams). Also, high-performance concrete may contain a large number of additives, such as different kinds of mineral and chemical admixtures and fibers, which may have different particle sizes, and some of the admixtures may interact with each other. Hence, the flow of a given concrete is usually measured using one of the many standard tests available that only partially measure the intrinsic flow properties of the material. Rheological measurements play an essential role in quality control (QC) of many liquid and semi-solid materials.

Two Point Tests

It is well established that the flow properties of fresh concrete at low shear rates approximate the Bingham model, expressed as follows:

τ = τ0 + μp ẏ (Equation 1)

where τ, τ0, μp, and ẏ are the shear stress, yield stress, plastic viscosity, and shear rate, respectively. Compared to a Newtonian model, the Bingham model incorporates a yield stress term τ0, and the viscosity is often replaced with plastic viscosity (μp). In Equation 1, the shear stress should be measured with at least two different shear rates to estimate the Bingham constants. Physically, the yield stress represents the force required to initiate flow, while plastic viscosity is a measure of the resistance of the mass to an increase in the rate of flow.

Rotational Rheometers

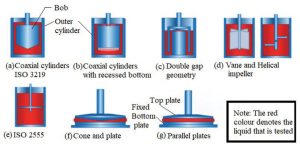

Several attempts have been made in the past to adapt traditional rotational rheometers (e.g., ASTM D7175:15), commonly used in asphalt binder testing, to measure rheological properties of concrete. Rotational rheometers for concrete apply continuous shear to the concrete specimens through rotational movement at controlled torque and speed. Rotational methods offer the advantage of being able to shear a sample continuously in order to achieve equilibrium and to monitor changes over time. These are basically dynamic tests. From the measurement of torque and rotation speed, the rheological parameters of yield stress and plastic viscosity can be calculated. Rheometers for concrete must be designed carefully due to the large and different sizes of aggregates used. A view of the different types of standard geometries is shown in Figure 3.

Figure 3. Different types of rotational rheometers (Source: Küchenmeister-Lehrheuer and Meyer). Reprinted with permission from Thermo Fisher Scientific.

Most geometrical configurations for concrete rheometers are based on coaxial cylinders, as shown in Figure 3a and 3b, consisting of an inner cylinder (called a bob), which is inserted into an outer cylinder. As shown, several geometries can be used for the bob, including a solid coaxial cylinder, a coaxial cylinder with recessed bottom (Figure 3b), double gap geometry (Figure 3c), vane, and helical impeller (Figure 3d). In a coaxial cylinder’s rheometer, the fluid between an inner and outer cylinder is sheared. A torque is applied to the outer cylinder, while the inner cylinder measures the torque. The vane and helical impeller geometries can be used instead of the inner cylinder. In impeller rheometers, a vane or impeller is inserted into the concrete and rotated at various speeds in an axial or planetary motion. The cone and plate (Figure 3f) or parallel plate (Figure 3g) rheometers are also commonly used with concrete. Parallel plate rheometers, consisting of two horizontal plates with one plate rotating relative to the other, permit small specimen size and direct analytical calculation of rheological parameters. In the parallel plate and coaxial cylinder rheometers, yield stress and plastic viscosity are calculated directly from the torque and rotation speed. In impeller rheometers, however, yield stress and plastic viscosity cannot be calculated directly. Hence, standard calibration fluids have to be used to establish the relationship between the measured torque and rotation speed. The surfaces of the coaxial cylinder and parallel plate are usually textured or roughened to prevent slippage between the concrete and the surface of rheometers.

Although concrete rheometers have been used with several types of concrete, such as SCC and fiber-reinforced concrete, they are not suggested to be used with stiff concretes. It is also important to note that different rheometers give different absolute values of the rheological parameters, but the degree of correlation of both parameters between any pair of rheometers is good. Differences in absolute values were attributed to factors such as wall slip, particle interference, and the use of different materials for calibration. Tattersall (U.K.) designed the first two-point rheometer in 1973, with an impeller rotating inside the concrete, placed in a vessel. Since then, it has been commercialized into the BML viscometer (Iceland, using a serrated cylinder), and the IBB rheometer (Canada, using an H-shaped impeller). Other commercial rheometers are the Bertta Apparatus, the BTRHEOM rheometer (France), the CEMAGREF-IMG rheometer (France), the UIUC rheometer (the University of Illinois at Urbana-Champaign), and the ICAR rheometer (the University of Texas at Austin). These different pieces of equipment have software built into them, which converts the applied torque and speed to yield stress and plastic viscosity automatically. These modern controlled-stress rheometers have allowed measurements to be made at significantly lower shear rates than previously possible. These rheometers show that at low shear rates, plastic viscosity is very high. Some rotational rheometers have been designed to be sufficiently small and rugged for use at job sites. More descriptions and comparisons of these rheometers are available in a NIST article by Ferraris and Brower (2000).

High-Performance Concrete (HPC)

High-Performance Concrete (HPC) is designed to give optimized performance characteristics for a given set of materials, usage, and exposure conditions consistent with strength, durability, workability, and service life. The significant difference between conventional concrete and HPC is essentially the use of chemical and mineral admixtures.

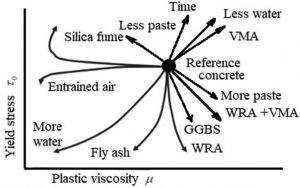

Figure 4. Effect of constituent materials on the rheological

properties of typical concrete (Adapted from Banfill, 2006). Reprinted with permission from ACI.

All aspects of mixture proportioning of HPC, such as cement content and characteristics, water-cementitious materials ratio (w/cm), supplementary cementitious materials (SCMs), chemical admixture dosage and type, aggregate properties and content, and gradation play an important role in its rheology. The Table and Figure 4 summarize the effects of these different components on the rheology of HPC. Except for the combined WRA + VMA behavior, Figure 4 shows the effect of individual components only.

To achieve better quality by limiting segregation, producing a good surface finish, minimizing pumping pressure, or controlling formwork pressure, it is necessary to balance the rheological properties of concrete. Ferraris et al. (2017) suggested the following:

- Control segregation by increasing the yield stress or plastic viscosity, keeping in mind that increasing both parameters excessively will lead to very stiff concrete.

- Achieve good surface finish by having adequate plastic viscosity; when it is too low, segregation will occur, and when it is too high, air bubbles cannot escape. If the yield stress is increased, consolidate the concrete to remove air.

- Decrease pumping pressure by decreasing plastic viscosity. Decreasing yield stress will not appreciably decrease pumping pressure.

- Reduce formwork pressure either by increasing yield stress or plastic viscosity.

Summary

Single-point tests like the slump test measure empirically only the yield stress, which alone is not sufficient to evaluate the flow characteristics of concrete. Two-point tests measure both yield stress and plastic viscosity. It is difficult to measure the rheological parameters of concrete as the ingredients of concrete have a broad range of particle sizes. Also, high-performance concrete may contain different kinds of mineral and chemical admixtures, and fibers which again may have different particle sizes. Some admixtures may interact with each other.

The yield stress represents the force required to initiate flow, while plastic viscosity is a measure of the resistance of the mass to an increase in the rate of flow. Rotational rheometers measure the torque and rotation speed of a bob that circulates inside concrete, based on which yield stress and plastic viscosity are calculated. Several geometries can be used for the bob. Several commercial rheometers also exist. All aspects of mixture proportioning of HPC play an important role in its rheology.■

References

ACI 238.1R-08, Report on Measurements of Workability and Rheology of Fresh Concrete, American Concrete Institute, Farmington Hills, MI, Feb 2008, 70 pp.

Banfill, P.F.G. (2006) “Rheology of Fresh Cement and Concrete,” in Rheology Reviews, pp. 61-130, British Society of Rheology.

Ferraris, C.F., Billberg, P., Ferron, R., Feys, D., Hu, J., Kawashima, S., Koehler, E., Sonebi, M., Tanesi, J., and Tregger, N. (2017), Role of Rheology in Achieving Successful Concrete Performance, Concrete International, ACI, Vol. 39, No. 6, June, pp. 43-51.

Ferraris, C. F., and Brower L.E., (Ed.) (2000) Comparison of Concrete Rheometers: International Tests at LCPC (Nantes, France), Oct., NISTIR 6819, National Institute of Standards and Technology, Gaithersburg, MD, 157 pp.

Ferraris, C.F., and de Larrard, F. (1998) Testing and Modelling of Fresh Concrete Rheology, NISTIR 6094, National Institute of Standards and Technology, Gaithersburg, MD, 61 pp.

Hu, C., and de Larrard, F. (1996) “The Rheology of Fresh High-Performance Concrete,” Cement and Concrete Research, V. 26, No. 2, pp. 283-294.

Küchenmeister-Lehrheuer, C., and Meyer, F., “Better rheological results: Create SOPs that drive sound rheological measurements,” Thermo Fisher Scientific Application White Paper No. WP 02 (https://assets.thermofisher.com/TFS-Assets/MSD/Application-Notes/MSD/Application-Notes)

Tattersall, G.H., (1991) Workability and Quality Control of Concrete, E & FN Spon, London, 259 pp.