An Unlikely Pair: Steel Trusses and Flat-Plate

The University of Pennsylvania’s Ronald O. Perelman Center for Political Science and Economics (PCPSE) serves as a unified facility dedicated to global social science teaching and learning. It opened to students for the 2018-2019 academic year.

The $77.6 million project involved a 54,440-square-foot renovation and reuse of the historic 1925 West Philadelphia Title and Trust Co. Building with the construction of a new 56,700- square-foot addition. Kuwabara Payne McKenna Blumberg Architects (KPMB) of Canada designed the project to integrate old and new. The combined facility contains a 120-seat auditorium, classrooms, collaboration areas, computing rooms, and faculty offices. LEED Silver Certification remains pending.

Exterior dusk view from 36th and Walnut Streets of the PCPSE on the University of Pennsylvania campus. Courtesy of Adrien Williams.

Keast & Hood structural engineers of Philadelphia, PA, provided structural design for the project, led by Principal Constantine G. Doukakis, P.E., and Associate Allison Lukachik, P.E., S.E., C.D.T.

Structural challenges involved a 30-foot-tall cantilevering steel feature stair, two 19-foot-tall steel transfer trusses to enable a column-free lower-level auditorium, and the use of concrete flat-plate floor framing to compensate for low floor-to-floor heights in the West Philadelphia Title and Trust building. To further complicate efforts, no structural drawings existed for the original building, which featured two variations on an existing concrete-encased steel structure. Through the use of 3-D structural analysis and team collaboration, the engineering solution applied structural gymnastics and more than a little creativity.

Existing Conditions

Shortly after the West Philadelphia Title and Trust building opened in 1925, an addition was built. Mostly indistinguishable from the exterior, the two separate campaigns revealed themselves through slight changes in the structural framing and discovery of a sizable rubble stone wall roughly separating the basement into halves.

Keast & Hood dug into historical archives maintained by the Athenaeum of Philadelphia and old city maps to confirm that not only was the building constructed as two sequential campaigns separated by only two years, but it was designed under two different architects. Unfortunately, drawings did not exist for either project, and the concrete-encased steel limited the engineers’ ability to gain much information via visual survey. The team used 3-D laser scan information and probes to understand the structure and identify beam sizes. Engineers found that the system changed slightly within the addition. Lightweight steel joist framing discovered at the second level revealed the original two-story banking space was infilled at some point. Although in good condition, the steel’s age meant it had limited strength. In locations where new usage necessitated higher loads, the concrete had to be removed, steel reinforcements added, and fire-resistive materials spray-applied to restore the fire rating.

Programmatic and Pragmatic

Acknowledging the limits of the existing building structure to minimize the need for structural reinforcements, the team placed high-occupancy spaces in the new building and lower-occupancy rooms in the original bank building. The new forum was one exception to this approach where reinforcement of the 1927 framing was introduced.

The design removed a significant portion of the second-floor infill to recreate the original grandeur of the ground floor. Inserted within the void previously occupied by an old stair and elevator towers, a new feature stair provides access to the auditorium. A basement location for the auditorium worked best with circulation and ability to accommodate the depth of sloped seating. However, functionality as an auditorium necessitated a column-free room.

Keast & Hood considered post-tensioned concrete because it could achieve both the large span and meet the low floor-to-floor height of the existing building, but recognized its future limitations. Making penetrations in post-tensioned concrete requires care to avoid cutting tendons, which carry a large amount of force. While controlled de-tensioning is both possible and safe when done correctly, the process can be costly. Since the ceiling of the auditorium forms the floor plate of a large classroom and circulation above, engineers wanted to avoid potential limitations and ensure the University of Pennsylvania had the flexibility for future changes without requiring costly structural interventions. When viewed in the context of the space and architectural objectives, steel proved the best solution.

Transfer Trusses

In the new portion of the building, two 19-foot-tall, 53-foot-long steel transfer trusses support four floors above and one floor below to enable the column-free basement auditorium. Steel beams frame between the trusses at the building’s first, second, and third levels, infilling the floor slab within the surrounding flat-plate concrete slab structure. The second floor frames into the bottom chords; the third floor frames into the top chords; and from the bottom, six steel hangers support the first floor. The concrete columns for floors four through seven and the roof bear on the trusses, which become integral to the structure of the entire building. These two trusses in effect support all levels of the building either through direct framing, hangers, or via columns that post up from their top chords.

Construction progress elevation view of long span, steel story truss with steel hangers down to the first-floor structure.

Flat-Plate Concrete

Most of the former bank building featured floor-to-floor heights of 12 feet. To accommodate comfortable ceiling heights of nine to ten feet, and to avoid awkward shifts of floor heights between the old and new parts of the building, Keast & Hood turned to flat-plate concrete. The solution kept the structure to the 12-foot ceiling height and accommodated mechanical, electrical, and plumbing runs in the ceiling space without infringing on the already tight space. At column locations where punching shear was a concern, stud rails within the depth of the concrete slab were utilized instead of large column drop caps, keeping the ceiling cavity open. Traditional steel with concrete slabs on deck would have compromised too much head height, reducing the ceiling heights to uncomfortably low positions.

Systems Integration

The use of steel to span the auditorium and support the addition, and the use of flat-plate concrete in the addition, required detailing to ensure compatibility of the different systems. Integration with the existing concrete-encased steel structure further complicated the process. Engineers used several programs within the Bentley RAM software suite to perform analysis and eliminate potential conflicts. Particular effort was made to manage and coordinate construction, including phasing between the two structural building trades.

Signature Stair

A 30-foot-tall cantilevering steel feature stair connects three levels of the conjoined building. The signature staircase provides primary access to the basement auditorium. Here, structural gymnastics compensated for horizontal thrust at the floor levels and provided support for the cantilevered condition.

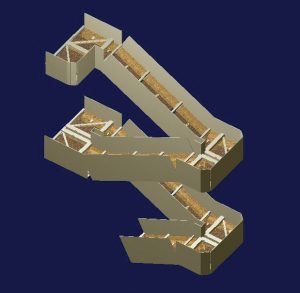

The stair cantilevers down from each floor like a sideways Z, attaches to the next floor, and cantilevers again. Sections of the slabs were removed and replaced with horizontal steel trusses that tie into the existing columns to deal with horizontal thrust at floor levels. These are capped with steel plates for support and aesthetic uniformity with the steel stair. The design eases the massive horizontal forces developed as a result of the cantilevered condition while not overstressing the slabs. A substantial concrete mass footing anchors the stair at the base and ensures horizontal loads do not transfer to the adjacent rubble stone basement wall of the existing building.

The stair solution required much collaboration between architects and structural engineers. Hidden horizontal tube steel trusses were incorporated at each landing to prevent twisting. Hidden steel tubes beneath the stair treads provide added support and stiffness to the stair assembly. Three-quarters to one-inch-thick steel plates serve double duty as the stair’s stringers and guard rails, giving the stair a sleek, industrial look. These plates also provide the stiffness necessary to cantilever out 30 feet from the floor slab, with minimal deflection experienced under code-prescribed loading conditions, and to ensure vibration issues common to feature stairs did not manifest. Challenges included determining depths into which structural elements could be concealed, understanding how the stair would be fabricated, and evaluating whether the handrail would be used structurally. Analysis efforts determined that the handrails were not required for the stability or reinforcement of the deep plate stringers, allowing their architectural expression to remain independent. The architecturally exposed steel also required careful detailing of welds for a clean visual appearance. Engineers used RAM Elements to perform analyses. The team engaged stair engineer Providence Engineering Corporation of Lancaster, Pa., who verified design and constructability, matching the structural team’s numbers exactly.

Creativity and Collaboration

The challenging constraints of the existing building inherited by the design team encouraged a high degree of creativity and collaboration that resulted in an impressive facility for the University of Pennsylvania.■