Practical Construction Detailing for 8-inch CMU Special Shear Walls

Certain types of special masonry shear walls require reinforcement hooks, typically 180 degrees, at the end of a masonry wall, but the cell dimension and grout clearance requirements can make installation problematic. When this happens, using a three-dimensional (3-D) technique allows for practical detailing and construction of horizontal reinforcement end hooks to vertical reinforcement as required by code for special shear walls (The Masonry Society, TMS 402-16, Section 7.3.2.6(d)). This 3-D technique twists the horizontal reinforcement so that the hook angles instead of lying flat. The twisting delivers code required grout space while providing a proper end hook. The hook is necessary for wall continuity allowing for ductile behavior. This article refers to 8-inch concrete masonry unit (CMU) walls with #4 reinforcement and coarse grout.

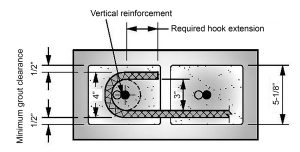

The flat 180-degree hook dimension is 4 inches overall (TMS 402-16, Table 6.1.8). For load-bearing CMU, standards require a minimum face shell thickness of 1¼ inches (ASTM C90). The flat dimension directly impacts the side clearance requirements (TMS 402-16, Section 6.1.3.5). With 7.625 inches overall width, 2.5 inches of face shell thickness, and a 4-inch hook flat dimension, it appears there is no issue (that is if #5 reinforcement, or larger, is not being used). Considering the minimum face shell dimension and perfect placement, the code requirements can be met with ⅛-inch tolerance as depicted in Figure 1. However, TMS 602, Article 3.4 B.11.a, allows for ½-inch tolerance in reinforcement placement. As presented in two-dimensional (2-D) construction drawing format when considering material and installation tolerances, the reinforcement does not fit.

The 3-D Solution

The hook orientation does not require flat horizontal placement in the wall. The Concrete Reinforcing Steel Institute (CRSI) Research Note on the “tilt” angle of end hooks (RN-2009-2) concluded: “hook tilt angle did not appear to have an effect on the maximum stress or displacement of the reinforcing bar.”

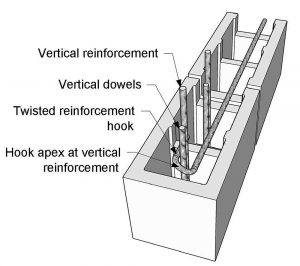

Since the horizontal reinforcement hook is not required to lay flat, a 3-D solution, i.e., twisting the hook, becomes an option and the 2-D issue disappears (Figure 2). The orientation of the hook does not affect the structural integrity; however, the apex of the hook must surround the vertical reinforcement to achieve a proper hook.

The hook prevents buckling of vertical reinforcement should spalling occur under high lateral loading. Research conducted by the Technical Coordinating Committee on Masonry Research (TCCMAR) on shear wall performance, and results assessed by Greg Baenziger and Max L. Porter (Iowa State University, 2010), showed that horizontal reinforcement not hooked to vertical reinforcement (i.e., there is slack) caused excessive spalling resulting in a negative impact on the ductility of the wall. Their recommendation was to assure there was no slack or there was a properly installed hook.

The Concrete Masonry Association of California and Nevada reports this issue is a common question. With today’s computer drafting software, the 3-D solution is easy to represent on construction drawings. Since special shear walls are performance-based, adequate structural performance requires a proper hook while maintaining proper side clearances for adequate grouting.■