Over the years, Leffert Buck (STRUCTURE, December 2010) replaced some of the wires, added anchorages, replaced the wood and iron suspended span, and finally changed the masonry towers with iron in Roebling’s Niagra Suspension Bridge (STRUCTURE, June 2016). The bridge, with its single track, outlived its usefulness by the early 1890s. Buck received the commission to build a new two-track bridge on the same alignment without interrupting traffic. His assistant in the calculations and his resident Engineer was Richard S. Buck, graduate from Rensselaer in 1887. The two Bucks would have an association lasting twenty years.

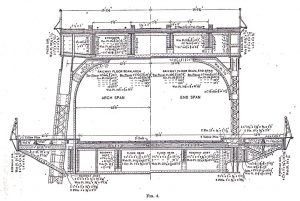

Buck had to choose between a three-hinged arch, similar to his earlier Driving Park Bridge in Rochester, a two-hinged arch, or a hingeless arch. In actuality, he only considered the first two types, asking himself “which is preferable, ease of calculation and adjustment, inconsiderable temperature stresses, and greater vibration, or greater rigidity with increased temperature stresses and difficulty of adjustment?” Once he had chosen his number of hinges, he had to decide how he would brace his arch. Three methods were used in the past. They were the solid-rib, similar to the Washington Bridge in New York City; the braced-rib, similar to the Eads Bridge in St. Louis; or the spandrel braced bridge, similar to his Driving Park Bridge. Having had the experience of Driving Park, he chose the two-hinged spandrel-braced arch, primarily for its greater rigidity.

Having selected his arch type, how could he build it without interrupting traffic on the suspension bridge? It was clear that he could not hang the new arch from the existing bridge without overloading it, making it inadequate to carry the required railroad traffic. He contemplated transporting material using a cableway supported on the existing bridge towers similar to the method he had used on the Verrugas Viaduct in Peru, but he determined the cost of the plant would be excessive.

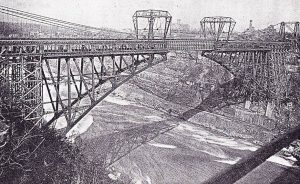

He decided to use Roebling’s bridge only for worker access and to carry members to their location on a track running on a cantilever off of the lower deck on each side. The members would then be lifted into place by a traveler, initially running on the falsework and later on the top chords of the new arch. The arch would be built as a cantilever with no erection loading being placed on the suspension bridge. Since the new bridge would be wider than the old, the two arches would be erected outside of the existing suspension bridge structure.

Placement of the cross bracing between the arches, which were directly under the existing bridge, required careful handling of the members with block and tackles anchored to the underside of the top chord. Drift pins or bolts secured all connections during erection. Most of the field riveting was done after the arch was closed.

The steel was fabricated and erected by the Pennsylvania Steel Company with John V. W. Reynders, another Rensselaer graduate, as chief engineer. Pennsylvania Steel was an up-and-coming company and, with this project, they earned a reputation which they would build upon in the rest of the century and the early part of the 20th century.

Since the two-hinged arch is statically indeterminate, Buck based his design upon work by Clerk Maxwell. Maxwell had developed an equation based upon the deformation of any member of the arch under unit values of the horizontal and vertical components of one of the reactions. His member sizes were designed utilizing the analysis technique contained in Professor Greene’s book on Arches. He determined the load in each member under a unit value horizontal reaction and a unit value vertical reaction and then determined their contribution to the horizontal reaction, summing these effects to obtain the total horizontal reaction. He started his analysis by assuming all the member sizes were identical, thus simplifying his calculation for the initial horizontal reactions. Once these values were known, the arch became statically determinate and forces in the members could be found under design loading. These forces would lead to new member sizes. This was an iterative process, requiring an estimated member size to start the process, and was extremely time consuming and laborious.

Since Buck decided to build the bridge utilizing the cantilever technique, he would have to design each member to carry its erection loading as well as its service loading. This, of course, increased the amount of calculation required.

Buck, however, decided to not rely entirely on these calculations. “The lower chords at the middle point were lighter than the speaker [Buck] liked to have them, and the middle portion of the top chords was very heavy; consequently, he increased the middle portion of the bottom chord by one-half the difference between the three-hinged and the two-hinged arch.” He further said, “for which he is not sorry.”

His skewback foundations were begun in 1895. He notched the foundations into the rock on the side of the gorge and built the masonry, with some concrete, directly on the rock. He then set his steel skewback on the masonry, anchoring it down with six 2½-inch-diameter bolts. Unlike any bridge prior to this, Buck decided to use a roller assembly rather than a pin to connect the structure to the skewback. He used this method because this type of bearing “reduces frictional resistance much as a ball-bearing does, and was adopted to avoid the use of an excessively large pin, with which movement is rather doubtful of realization.”

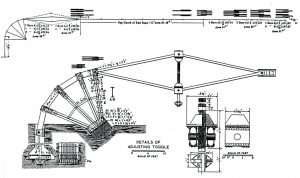

Buck built falsework out from the banks to support the approach spans and traveler tracks. The top chords of the approach spans were strengthened to provide tension members that would be utilized to support the cantilevered segments of the arch during construction. Buck designed and built a unique toggle device and anchorage.

A short segment of falsework was erected under the arch near the skewbacks to commence the construction of the arch. Once the arch reached this point, a diagonal was dropped down from the ends of the anchor bars to support the first portion of the arch. This cable, of course, in addition to placing loading in the anchor bars, also placed loading on the end vertical of the spandrel bracing. This member was therefore significantly larger than it needed to be to carry its service loadings. Once the end vertical and first diagonal was erected, the end post was inclined a specified amount towards the shore using the toggle. The next vertical and first top chord member were placed and pinned to the anchor chains. The traveler then moved off of the falsework onto the top chords of the arch, and the next panel erected and tied back. This process was repeated six more times from both ends of the bridge until the arches met in the middle.

He decided not to plane the ends of his center segments until the ends of the arch approached one another (with each arch six panels out). At this time, he measured the distance between the two ends of the converging arches. Due to atmospheric conditions, he did not trust the accuracy of this measurement and decided to plane the ends to plan. As the pieces were put in place, “the closure at the middle was anticipated with considerable interest and anxiety. The absence of the center hinge rendered great accuracy in laying out the work necessary, in order to secure proper closure and distribution of load between the top chord and the rib.” He anticipated that if “the stresses in a two-hinged arch were carefully calculated through all the members when the dead load alone was on, and the shortening of members in compression and the lengthening of members in tension accurately worked out, and the increase or decrease in the length of each as indicated by these calculations made; the top chords being in tension and the lower chords in compression in erection, the top chords would naturally meet first when the bridge came together.” This, however, did not happen.

When the final pieces were placed, there was a gap of 8 inches at the bottom chords since the arches were drawn back to erect the arches above their final position. They then slackened all the toggles and, to their surprise, the bottom chords met first, leaving an approximate gap of ½ inch in the top chord. They had planned on the top chord carrying about 350 tons in this state and, with the gap, it obviously was carrying no load. They then removed some of the drift pins and bolts, allowing the joints to close which reduced the gap to ¼ inch.

To close this gap, they built a new toggle that “was improvised largely from material on the ground.” They calculated that the ends would have to be separated by 1 inch to place a load of 350 tons in the top member. Turning “but one nut, the toggle was compressed on both sides and with a given pull on the wrench, and a careful estimate of friction, the required pressure could be very closely obtained.” They then inserted a 1-inch-thick shim with the same cross-section of the top chord and released the toggle, thus placing the desired loading in the top chord. With this step complete, they finished riveting the arch using a 70-ton pneumatic riveting machine operated by a compressor plant located on the American side. They then began construction of the deck structures and the transfer of load from the suspension bridge to the arch bridge, all the time maintaining traffic on the bridge.

The new lower floor structure was placed to pick up the bottoms of the existing trusswork and the existing lower deck. The suspenders and stay cables were then cut, transferring the entire load of the Roebling bridge to the Buck bridge. The main cables were then removed by cutting the wrapping wire with axes, and by cutting the strands from their shoes and dropping one strand at a time. The upper floor was then placed following a technique similar to that done by Buck when he replaced the wood and iron suspended structure of Roebling with all iron in the 1880s. “The same track alignment was preserved, and the same rails and ties were used temporarily after the new floor beams and stringers were in place.” They replaced two panels per day in the two-hour windows in which they had to work. The towers were then removed and the plate girder approaches installed. Over time, the tracks were replaced as they went to the two-track configuration.

Buck designed the bridge to carry 10,000 pounds per running foot, but he could not find any locomotives that would place this loading on the bridge. He, therefore, tested the bridge under 6,500 pounds per running foot by making up two test trains. “Each train consisted of two heavy Lehigh pushers, four of the heaviest Grand Trunk locomotives at hand, and nine coal cars…some load was put on the lower deck, chiefly on the end spans.” Under this loading, the maximum deflection was 13⁄16 inch. Differences at the quarter points, due to the test trains being at a quarter point, was less than 1¼ inch.

His brothers in the bridge-building field acknowledged Buck’s triumph. Gustav Lindenthal wrote that, “the use of riveted connections in the Niagara Bridge is a remarkable deviation from American practice; but that it was a proper choice cannot be questioned, and it is the more creditable to the engineer as the temptation to use pin connections, for greater ease of erection, was one not easily ignored.” He did not like the rollers at the skewbacks, writing that they “will hardly find imitators.” J. M. Moncrieff, an English engineer, wrote, “the engineer, and all concerned in the work, are to be congratulated on the successful completion of so handsome a structure under difficult conditions of erection.” Henry Tyrrell, in his History of Bridge Engineering, wrote, “the opening of the Niagara Railroad Arch marked a new period in American bridge design. The remarkable example of modern engineering was completed in 1896 at the cost of $500,000.”

Erection on the bridge started September 17, 1896, and it was tested on July 29, 1897. The bridge was completed on August 27, 1897. It was, with its 550-foot span, the longest railroad bridge in the world for three years, having replaced the Roebling Bridge which held the record prior to this time. Within five years, its span was exceeded by the Forth Bridge, the Lansdowne Bridge, the Red Rock Bridge, and the Memphis Bridge. All were cantilevers designed for railroad traffic only. It remained the longest railroad arch bridge for many more years.

With this bridge complete, Buck would, after 21 years, finish his work on rehabilitating and replacing Roebling’s Bridge. The existing bridge is truly Buck’s creation and has served as a model for subsequent railroad arch bridges.

The bridge was opened with a three-day, international celebration, September 23 to 25, 1897, sponsored by the Grand Trunk Railway. The Niagara Falls Gazette wrote, “today Niagara Falls is celebrating the achievement of one of the greatest engineering feats of the day – the completion of the new railway suspension bridge, connecting Canada and this country with one of the most magnificent structures of the world.” The actual opening took place on September 23 at 1:30PM when, to the accompaniment of four bands, the mayors of both Niagara Falls’ “met in the center of the bridge, and there, standing upon a massive steel link connecting two of the greatest nations of the earth, each grasped the hand of the other in a hearty and sincere grip…” The press could not say enough good about the bridge and in this account called it “one of the most miraculous mechanical and engineering works of man.” There were no speeches “because it would have been impossible to find any place where the crowds could be accommodated, and the management of the celebration had decided that there will be no public speaking.”

The Bridge was rehabilitated in 1919 by Charles Evan Fowler, who wrote a lengthy article in the Transactions of the American Society of Civil Engineers. In discussing Fowler’s article, F. E. Schmidt concluded, “taken as a whole, the facts developed in Mr. Fowler’s investigation and throughout the subsequent revision of the structure, constitute a most gratifying testimonial to the excellence of the design embodied in the original bridge. It does not seem to be extravagant to say that the design was a generation ahead of its time.”

The bridge still stands after 120 years of serving railroad and vehicular traffic. It is the oldest structure spanning the river and has fully lived up to the claim of the Engineering News at its opening that it is, “capable of serving the purpose, barring injury by corrosion, a hundred years from now as it is today.”▪