West Coast Seismic System Invades NYC

The New York State Office of Mental Health (OMH), in association with the Dormitory Authority of the State of New York (DASNY), is implementing a major modernization program for the Bronx Psychiatric Center, including a new 180,000 square feet, 156-bed, Adult Behavioral Healthcare facility. The amorphously-shaped five-story building creates a supportive and humane environment for both consumers and providers while maximizing natural light, emphasizing the connection with the outside environment and improving spatial orientation. The Adult Behavioral Health Center will be the first new adult inpatient facility in New York State in nearly two decades.

Rendering of Adult Behavioral Healthcare Facility.

While many New York City skyscrapers benefit from the support of billion year-old 60+ tsf (tons per square foot) Manhattan Schist, other sites contend with fill and deep organic layers, saddling low-rise structures with amplified seismic design forces. Located in the Westchester Square section of the Bronx, the site was originally a wetland through which the Westchester Creek flowed. The facility sits on 4 million cubic yards of fill materials generated from the construction of the Cross Bronx Expressway. The fill was placed over salt marsh deposits and river alluvium overlying Pleistocene glacial and glaciofluvial sediments. While a bedrock bearing surface was found an average of 58-feet below grade, the presence of up to 15 feet of very soft, highly compressible, organic silt and clay with peat resulted in a Site Class F categorization. The site-specific ground motion analysis performed in SHAKE 2000 yielded acceleration parameters of SDS = 0.80g and SD1 = 0.17g – resulting in building Seismic Design Category D.

Historic map showing Westchester Creek in the site.

With no practical height limitations, structural steel was selected for the superstructure to minimize the gravity load on the 63-ton, 12-inch diameter concrete filled pipe piles, and a special concentric braced frame lateral system was developed. As the non-linear time history design progressed, even with a seismic response coefficient of 6, the frame members and associated foundation elements were enormous for a low-rise building, creating many space-planning challenges where walls needed to expand and bump out around elements. With design collaboration across STV offices, structural engineers in Los Angeles suggested using a buckling restrained braced frame (BRBF) system to enhance performance, reduce member size, and reduce cost.

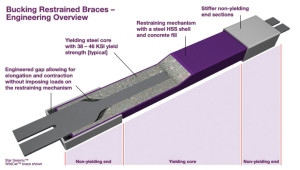

Now widely used in high seismic zones, BRBFs are codified and a performance leader among post-Northridge systems. BRBFs do not exhibit the unfavorable buckling characteristics of conventional braces and have a full, balanced, hysteretic behavior, with compression-yielding similar to tension-yielding. This performance is achieved by decoupling the stress resisting and flexural buckling resisting aspects of the compression strength. The primary brace component is actually a simple steel plate, called the core; with its size calculated based on required tension area. The core is then surrounded by a steel tube, filled with concrete, and capped on each end so that it exists unbonded in the end elongation zones. Because the steel core is restrained from buckling, it develops nearly uniform axial strains across the section resulting in efficient energy dissipation. In addition, the near balance between tension and compression capacities greatly reduces the brace connections since they are sized based on the expected yield capacity of the member that is not controlled due to a buckling limit state. With an enhanced seismic response coefficient (R=8), better overall performance, reduced member sizes, and smaller, easier connections, estimated structural system savings are on the order of $2.40 per gross square foot for a representative 6-story building with a Special Concentric Braced Frame (SCBF) [cost savings data acquired from a study presented at American Institute of Steel Construction’s (AISC 2007 NASCC Steel Conference).

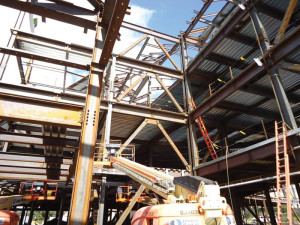

Wildcat braces installed.

While the overall project benefits seem obvious, there were still two major hurdles to overcome for this project – introduction of a new system to East Coast steel erectors and use of a proprietary component in a state funded project. STV’s LA office worked with Star Seismic to develop a schematic BRBF layout for the new Adult Facility and findings were presented to DASNY and LiRo, the construction manager. The presentation described the system components and outlined how the BRBF’s would reduce architectural and service interference with slender elements and smaller gusset plates, and also reduce erection time with single pin connections. With the BRB system, no stiffener plates are required due to its patented collar and there is a significant reduction in welding since only simple fillets are required. Erection is fast and simple since each element has a tolerance of +/- 2 inches. However, what quickly won over the audience was the estimated $500,000 in material savings alone for the combined superstructure and foundation.

LiRo used the presentation and contacted several steel erectors, confirming that the only hurdle for an East Coast project location would be the shipping time for the brace elements coming from Star Seismic’s facility in Utah. In addition, LiRo explored the other two companies that manufacture similar bracing systems, getting project-specific quotes for comparison. After analyzing the pros and cons of each system, STV and LiRo recommended to DASNY that the proprietary Star Seismic Wildcat system be specified exclusively for this project to gain the time benefits of including Star Seismic as a design team member, since the costing due diligence exercise was performed. DASNY agreed and prepared a project specific waiver that allowed this proprietary system to be included as a component of the competitively bid structural steel package.

An additional benefit to the project that was not originally realized was the inherent submittal expedition that naturally occurs with the interrelated design. Most of the design and coordination effort between STV and Star Seismic happened prior to contract award; therefore, Star Seismic was able to produce shop drawings and calculations in only two weeks after award. With the submittal approval, braces were manufactured and delivered to the job site within six weeks.

Buckling restrained brace cross-section.

The Adult Behavioral Health Center is the first building in New York City, and the entire Northeast, to use the Wildcat buckling restrained braced frame (BRBF) with moment resisting beam-column connections as a lateral system. The project challenges were overcome thanks to the collaborative spirit encouraged by the owner, the designers and the contractors, all of whom began cooperating early in the design phase and continued to do so throughout construction. Completion of the LEED Silver facility is on target for the fall of 2015.▪

Project team

Owner: New York State Office of Mental Health (OMH); Dormitory Authority of the State of New York (DASNY)

Structural Engineer, Architect, Geotechnical Engineer: STV Incorporated, New York / Los Angeles

General Contractor: ARC Electrical & Mechanical Contractors Corp.

Steel Fabricator, Detailer and Erector: Orange County Ironworks (OCI) (AISC Member)

Construction Manager: The LiRo Group