The alkali–silica reaction (ASR) occurs over time in concrete between the alkaline cement paste and reactive non-crystalline (amorphous) silica, which is found in many common aggregates. This reaction causes the formation of a calcium-silicate-hydrate (C-S-H) gel that expands the affected aggregate. This gel increases in volume with water, and exerts an expansive pressure inside the material that causes it to spall and break the cement bond, leading to the failure of concrete elements. The mechanism of ASR concrete deterioration can be summarized in the following four steps (Tantawi, 2014):

1) Water mixed with cement powder becomes an alkaline solution that attacks the siliceous aggregate, converting it to viscous alkali silicate gel.

2) The reaction consumes alkali generating dissoluted Ca2+ ions that react with the gel and convert it to hard C-S-H.

3) This bulky hardened gel generates expansive pressure that cracks and spalls the aggregate.

4) The expanding aggregate then cracks the cement allowing water to infiltrate and accelerate the deterioration process.

Water deterioration is particularly critical in the U.S., especially the Northern regions because of the freeze-thaw cycles that occur during winter. A large number of structures in northern climates suffer from ASR. Since a susceptible aggregate differs very little in appearance from an inert aggregate and, in the 1800s and 1900s, there was little understanding of the destructive nature of reactive aggregate, there was little thought about excluding such aggregate from concrete. In fact, ASR-prone aggregate, in the right environment, will have an indefinite service life, which adds to the challenge of correct identification.

Typical look of a wall suffering from severe ASR damage. The failure is occuring due to the aggregate of the wall expanding and pushing out the outer layer.

As the process of deterioration in concrete structures became more widely known and more pronounced, contractors and designers shied away from the use of such aggregates and the concrete product became less of a concern. A recent reappearance of ASR in concrete aggregate may be the result of the reduced availability of natural stone aggregates of high quality, and a commercial need to resort to less durable aggregates.

Mr. Barnes’ first experience with compromised aggregate occurred approximately 30 years ago, when he was hired to determine why a concrete retaining wall was crumbling without apparent signs of deterioration of the reinforcing bars within the wall. At the time, Mr. Barnes performed the initial tests for known deterioration causes such as chloride contamination and carbonation. After the initial assessment, the tests did not have to extend further since both of these known deterioration mechanisms affect the steel reinforcement and yet no damage of this sort was observed on the wall. Concrete cores revealed a reasonable compressive strength (3500 psi) and laboratory analysis quickly ruled out reductions in concrete durability due to low air content; although, the air content was estimated at no more than 2-2.5%. At a time when petrographic analysis had not become widely accessible, the engineer had to rely on visual observation of concrete through a magnifying glass to estimate its constitution. The aggregate was large, up to an estimated 2-inch diameter and well graded. Its texture hinted that it was not river washed but taken from a pit. Finally, after what appeared as multiple aimless hunts, the first solid pattern of failure was established: the larger aggregate appeared quite fragile as it split in several directions, although some looked intact. Upon removal of the concrete binder, the aggregate consistently would fall apart while being held. After comparing these observations with concrete deterioration literature, Mr. Barnes hypothesized that the aggregate was suffering from Alkali-Silica Reaction. This theory was confirmed when the results of a through-wall excavation revealed that the water dependent reaction receded upon further excavation into the center of the wall and then increased again as the excavation approached the other side of the wall. The phenomenon seemed appropriate, as the surface on both front and back of the wall was subjected to greater moisture compared to the concrete within the depth of the wall.

Through the years, CBI Consulting, Inc. has tried to deal with ASR deteriorated concrete in a variety of ways. Some of these projects have benefited from new chemical technology and largely from common sense. CBI has observed that concrete with ASR aggregate, which has not deteriorated, does not suffer a strength reduction. Removing the deteriorated concrete to a depth where sound concrete is recovered, followed by pinning and recasting of concrete, has extended the life of affected structures. Although only one of the repairs CBI has guided over the years have been fortunate enough to have detailed post repair studies, it has been their experience that in an exposed environment, cement-based patches over ASR-prone aggregate concrete do not stop the deterioration; rather, they only slow it down.

To provide additional protection, CBI also recommends applying waterproofing membranes. In the U.S., the most commonly applied preventive and remedial measures are those which control the ingress of water in the concrete (Tantawi, 2014). Waterproofing coatings are commonly used for this purpose. A successful coating has to fulfill the following requirements:

- Be chemically resistant to the alkalinity of concrete.

- Have sufficient adhesion and water vapor permeability (prevent water from being trapped inside the concrete).

- Be compatible with the expansion of concrete and be water repellent.

The research paper by Santos, et al. (Lisbon, Portugal) indicates that a large number of studies have been conducted to evaluate the ability of coatings to mitigate the advancement of ASR and many present contradictory results.

These results have spurred a new research interest in testing methods that modify the expansive properties of the ASR products, one of them being the use of lithium salts. This phenomenon was first published in 1951, when the American Concrete Institute issued a study by McCoy and Caldwell that provided data showing that the incorporation of various lithium compounds (LiCl, Li2CO3, LiF, Li2SiO3, LiNO3, and Li2SO4) in mortars (ASTM C227) containing highly reactive silica could help control the alkali-silica reaction provided the lithium was present in sufficient quantity. In 2007, the FHWA published a report titled The Use of Lithium to Prevent or Mitigate Alkali-Silica Reaction in Concrete Pavements and Structures. Within the document, the FHWA establishes that the required amount of lithium to suppress expansion is based on the reactivity of the aggregate and the ratio of alkali to sodium plus potassium in the original concrete mix. The following molar ratio is used to obtain the recommended dose to control ASR (FHWA-HRT-06-133 Section 4.1):

[Li]/[Na+K] ≥0.74

The report also indicates that lithium additives appear to be more effective when applied to rapidly reacting aggregates such as those containing opal, chert or volcanic glass; meanwhile, they are less effective with slowly reacting aggregates such as those containing microcrystalline or strained quartz. In this report, Section 4.3, the FHWA provides recommended testing methods to help estimate the effectiveness of the lithium to control the ASR under evaluation.

Exposed concrete deck and beams suffering from ASR. Area was patched 20 years ago and the lifetime of the patches has been reached. Waterproofing coating after replacing concrete surface would extend repair lifetime.

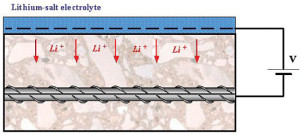

In restoration cases where minor patching will take place, the surface application of lithium compounds can help slow down the ASR. Laboratory studies (Stark et al, 1993; Stokes et al, 2000) have confirmed the positive effect of topical applications on shallow and small repairs. No significant improvement results have been observed in larger specimens. This triggered a study by Whitmore and Abbot in 2000, where they used electrochemical impregnation techniques to increase the penetration of the lithium compound on large structures. The technique is very similar to that of electrochemical chloride extraction technique. An electrode anode is applied to the concrete surface. The lithium electrolyte is ponded at the surface and a D.C. voltage is applied between the anode and the embedded steel (reinforcement) to drive the electrolyte into the concrete. A current of 60 volts appears to be the most effective, achieving a significant decrease in alkali reaction 2 inches into the surface. Electrochemical applications should be considered when large areas are affected and a long term protection mechanism is feasible.

In summary, practical suggestions for the determination of ASR in the field and employing feasible treatments include the following:

- Where appropriate, such as with upturned exposed beams, copings, parapets, buttresses, and piers, wrapping to exclude water can extend the surface life.

- As an engineer, when you encounter deteriorating concrete, run through your mind the usual culprits: chlorides, carbonation, mechanical abuse and now, ASR. In a salt-free environment (a concrete building façade), look for reduced concrete cover over the reinforcement made all the more sensitive by carbonation of that concrete. Carbonation reduces the natural alkaline passivity of cement around reinforcement.

- In marine environments along the coast, or in parking structures where salts can be brought in by vehicles, look for chloride contamination that can lead to electrical chemical deterioration (rust) of reinforcing steel.

- In older structures, look for the characteristic “map cracking” on the surface of the concrete that may be an indicator of an expansive aggregate (ASR) that is increasing the volume of the concrete, which exceeds the cement paste binder aggregate’s tension capacity. This phenomenon has also been referred to as a “varicose-vein” surface.

- In recent years, chemical admixtures have come on the market that improve the durability of the concrete by increasing impermeability. Some of those products are marketed under manufacturer trade names. Using some of those same products in a topical application may be helpful. Where deteriorated surface concrete can be removed and replaced to extend the service life, but it is not possible to provide a waterproofing wrap, consider the possibility of improving the waterproofing characteristics of the concrete internally by applying a densifying material topically to the interface between the ASR-prone aggregate and the new concrete surface treatment.▪

References

Tantawi, Saad (2014), A Comprehensive Study of Alkali-Silica Reaction Effect on Reinforced Concrete. (Introduction Section, Pages 3-4).

FHWA (2007), The Use of Lithium to Prevent or Mitigate Alkali-Silica Reaction in Concrete Pavements and Structures. FHWA-HRT-06-133

Santos, A., Salta, M. et al, National Laboratory of Civil Engineering, Lisbon, Portugal. Research on the Suppression Expansion due to ASR. Effect of Coating and Lithium Nitrate.

McCoy, W.J. and Caldwell, A.G. (1951), A new approach to inhibiting alkali-aggregate expansion, Journal of the American Concrete Institute, vol.47, pp.693-706.