Advanced Steel Curtain Walls Provide Enduring Beauty

When San Francisco’s Hallidie Building opened in 1918, its seven-story glass and steel skin launched the era of glass curtain walls. Using the strength of reinforced concrete and structural steel, the building team suspended the glass panes in a steel framing grid to create the illusion of a floating wall.

While innovative, early curtain wall systems like the one in the Hallidie Building had shortcomings. One in particular was steel’s vulnerability to corrosion. As a result, aluminum’s lightweight and durable form became the material of choice for glazed curtain wall framing after it was adapted for use in buildings in the mid-20th century.

Today, nearly half a century after aluminum entered the curtain wall scene, manufacturing advances are allowing building professionals to capitalize on steel’s strength in interior and exterior glazing applications, such as minimizing sight lines with small mullions and providing large free spans at the podium level of buildings.

To achieve these results, manufacturers have developed two fabrication methods. The first uses a roll-forming technique in which continuous steel coils are forced through dies and laser-welded into closed, structural profiles. Under the second method, a laser cuts long length (up to 49 feet) steel plates (0.15 to 1.5 inches thick). Manufacturers then laser weld them into C, T, I, H, or L profiles, or custom shapes, as required. The laser welds are continuous and significantly smaller (radius < 0.07 inches) than conventional fabrication welds, which allow the shapes to be analyzed and used as composite, rather than assembled members.

Using the above methods, manufacturers can produce steel frame members in lengths and shapes not previously possible with hollow metal, hot-rolled or welded steel frames. From protection against corrosion to support for high-performance applications, well-designed steel curtain wall systems use this versatility to provide enduring beauty.

Protection from the Elements

To preserve the appearance of steel curtain walls, modern manufacturing methods help overcome earlier problems with moisture intrusion and corrosion.

Moisture Intrusion

To prevent water in the glazing cavity from contacting the steel back members, advanced steel curtain wall systems include a continuous joint gasket across the full width of the frames. Through the gasketing, water is also kept off the tops of glass units and is directed to the vertical frame members. This is one of the factors that allows water penetration resistance per ASTM E331, Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors and Curtain Walls by Uniform Air Pressure Difference, to reach a minimum of 15 psf.

The continuous face gaskets cover the surfaces of the framing in the glazing pocket to provide a critical safeguard against moisture. The installer seals the lapped gasket joints at horizontal-to-vertical connections to further aid in preventing water intrusion. In general, steel curtain walls with proper gasketing do not require zone damming, as is typical with aluminum pressure plate systems. This eliminates the need for weeping at every horizontal pressure plate, thus reducing fabrication and installation time as compared to conventional aluminum systems.

Once the framing is erected and the gaskets are sealed, these steel systems use more conventional aluminum or stainless steel cover caps and pressure plates to hold the glass to the framing. Self-sealing fasteners penetrate the gasketing, but do not provide access for water penetration. Structural silicone glazing uses sealants specific to the application to retain the glass to the framing in lieu of pressure plates and covers, as is typical with aluminum systems.

Weather seals around the perimeter of the framing are made to gaskets at the back of the glazing pocket, to special extrusions or to perimeter details in plane with the glass instead of to the framing. Placing perimeter seals in front of the steel eliminates any chance of water contacting the material behind the seal. This ensures greater protection from corrosion once the building is completed.

To protect against corrosion, modern steel framing is available with double-sided pre-galvanization and factory-applied finishes.

Corrosion

To preserve the curtain wall’s appearance and protect against corrosion, modern steel framing is available with double-sided pre-galvanization and factory-applied finishes. For instance, steel framing may be prefinished with liquid zinc and top-coated with a durable primer and finish color to match virtually any design scheme. A variety of finishes are available, including powder coating and liquid-applied finishes specifically formulated for steel. Typical finishes applied to aluminum, such as liquid applied fluoropolymers, are not suitable for steel.

Carbon steel members, when formed from coil stock as described above, are protected from corrosion after production and during fabrication by pre-galvanized finishes applied to the coils before forming. Powder coating or liquid applied finishes can be applied with proper cleaning or blasting, depending on the quality of the required finish.

Fabrication is generally completed before finishes are applied to reduce any chance of damaging the finish during sawing, welding, drilling or final assembly. This also ensures minimal coatings are applied on rough edges that would otherwise be exposed during shipping to the jobsite, as well as installation until the building can be “dried in” and protected from water contact.

As with any specialty glass and framing system, product nuances vary by manufacturer. Consult the supplier’s documentation for specific installation instructions, particularly for more complex steel systems, such as structural silicone glazed steel curtain walls.

Galvanic Action

Galvanizing exterior exposed metal is a recommended best practice; however, it is not ideal to apply finishes over the galvanized surface. The galvanizing tends to bubble the finish, resulting in a rough, usually unacceptable surface appearance.

Another option is to form the framing members from stainless steel alloys. Generally speaking, Series 304 is the only alloy currently used in the rolled profile methodology (alloys such as Series 316 are too brittle when rolling). Other stainless alloys require more fabrication time. For example, the 316 Series requires slower saw and drill speeds, thus taking longer to fabricate. As such, checking with fabricators prior to specifying a stainless alloy is recommended.

For steel curtain walls with aluminum pressure plates, galvanic action can occur. To reduce corrosion between the two dissimilar metals, suppliers can connect the aluminum pressure plates to carbon steel back members with stainless steel pressure plate screws. As these metals are in close proximity to each other in anodic polarity, they do not tend to corrode as fast as metals that are further apart on the electromotive scale. The supplier can coat the metals with a non-conductive paint or finish to effectively isolate the two materials.

Steel’s greater load carrying capacity allows building teams to increase glass sizes in steel frames.

Support for Demanding Applications

Slender, versatile, and strong, steel framing offers several significant performance advantages over traditional steel and aluminum mullion curtain wall systems.

Greater Load Carrying Capacity

Steel has a Young’s modulus (E) of about 29 million psi, compared to 10 million psi for aluminum. As a result, steel frames deflect less, providing a substantially greater load capacity. This helps ensure the amount of deflection does not compromise the strength of the steel members, causing bowing, sagging or joint failure. It also aids in protecting glass lites from being forced out of place. These benefits can help building teams preserve the long-term appearance of the framing and reduce maintenance costs.

From a functional standpoint, steel’s greater load carrying capacity allows building teams to increase glass sizes in steel frames versus aluminum frames of the same shape. It also enables greater free spans than traditional steel and aluminum systems.

For example, given 5-foot mullion spacing at a 30-lb/sf-wind load, an aluminum mullion of 2.5 by 7.5 inches, including the glass and exterior cap, can span 12.5 feet. Due to steel’s strength, a similarly sized profile of 2.4 x 7.6 inches would only deflect one-third as much under the same conditions. As a result, it is possible to increase the length of the steel mullion in this instance to span approximately 16.3 feet – a 30 percent increase over its aluminum counterpart.

As with any curtain wall system, variables such as center-to-center location of verticals, span length, and structural loads have an impact on the size of the framing member required to support the project’s performance criteria.

Steel veneers allow for attachment to virtually any structural component that can support the curtain wall system’s imposed loads.

Design Versatility

Curtain walls that incorporate modern steel frames can support a wide range of design schemes. For instance, steel veneers allow for attachment to virtually any structural component that can support the curtain wall system’s weight and imposed loads (i.e., wind loads, snow loads). As such, they can provide building teams with exceptional design freedom.

The strength and versatility of steel mullions also enables curtain walls of various heights and shapes. The maximum allowable height for single- and multi-story steel curtain wall installations depends on factors such as applied loads and thermal expansion and contraction. However, the primary factor influencing the maximum height is where the curtain wall’s dead load will bear on the structure.

For example, in a recently completed six-story wall, the project structural engineer required each floor to carry the imposed curtain wall dead load, rather than have the wall’s full weight (approximately 25 psf due to thicker fire-rated glass, not the steel frame) imposed on the structure at the lowest level. The steel mullion was sized at 2.3 x 7.1 x 0.1-inch thick walls, and required a 0.37 inch dynamic splice joint at every floor. The structure of the building had to be increased to limit the live load deflection to 0.25 inch at these conditions.

In another example, on a project with a 55-foot clear span in an open atrium, the steel mullion was sized as a 4 x 17-inch rectangle. It weighed 100 lb/linear foot due to a moderately high wind load and wider-than-normal spacing between vertical mullions. In this case, the dead load was imposed on the foundation wall at the base of the curtain wall, and a moment splice was introduced since it was not possible to fabricate and ship a 55-foot tall mullion as a single piece.

It is important to note the project structural engineer offered to design the structure with a moment connection at the base of the wall, which would have reduced the weight of the mullion by 50 percent. However, since the reaction imposed on the foundation was too great, the mullion stayed robust as described.

Energy-Efficient Framing

As the connection point between the glazing and perimeter details, modern steel frames can help create a sound building envelope.

Condensation Resistance

In modern steel curtain wall systems, the absence of metal in the cold space of the glazing pocket, combined with narrower-frame profiles, reduces the potential for heat transfer. This, in turn, lowers the risk of interior condensation. The condensation resistance factor (CRF) for steel curtain walls typically ranges from 40 to 63, depending on the type of glazing used. More energy-efficient glazing can help design teams achieve a higher CRF.

Since curtain walls and windows with a CRF appropriate for the local climate and building design typically have less interior condensation (or ‘sweating’) on frames, proper specification is crucial. The American Architectural Manufacturers Association (AAMA) and other associations provide guidelines for selecting systems with the appropriate CRF. However, it is important to note the condensation resistance factor they recommend is a weighted average. It does not take into account cold spots and other peripheral factors. As such, thermal modeling software can provide value for projects where condensation control is a concern, including cold-climate, high-humidity applications. These programs factor in numerous variables, including proximity to perimeter heating elements, to help estimate the air temperatures along the inside surfaces of the glass and frames.

Heat Gain/Loss

Many curtain wall framing materials have high thermal conductivity compared to other elements of the building envelope, creating assemblies susceptible to summer heat gain and winter heat loss. To overcome this challenge, design professionals often pair framing systems with low-emissivity (low-e) glass or other energy-efficient glazing. While center-of-glass (COG) thermal performance values improve, the system’s overall thermal efficiency remains substantially less effective where the captured or retained glass edge meets the supporting frames.

With a thermal conductivity of approximately 31 Btu per hour (about 74 percent less than aluminum), steel can help reduce the potential for heat gain and loss between the glass and frames. Its performance is equivalent to that of thermally broken aluminum frames, allowing the steel frame profiles to help reduce heat flow. As an added benefit, some advanced steel frames do not necessitate a traditional thermal break due to the design of steel profiles. This helps lower the potential for heat transfer and interior condensation on the frames by providing a significantly smaller area of steel for heat to pass through. In addition, the strength of steel allows for ‘heavy’ triple glazed insulated glass units (IGUs) while maintaining the ability to provide large glass sizes and minimal sight lines – all advantages over aluminum.

Thermal Expansion

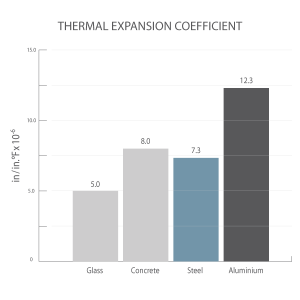

Steel expands and contracts at a rate about 50 percent less than aluminum. Its thermal expansion coefficient of about 12 x 10-6 x 1/K is comparable to glass and concrete, which are approximately 9 and 10 respectively, while aluminum is about 24.

Since steel, glass and concrete expand and contract at similar rates, steel can work in close conjunction with its surrounding materials to help ensure a sound building envelope as the temperature changes. This can also reduce the size of perimeter sealant joints, especially at locations where expansion is being addressed. These are crucial specification considerations for buildings in climates with extreme morning-to-midday temperatures and distinct seasonal changes.

Fire Protection

Fire-rated curtain walls also benefit from the new generation of steel frames. Using new manufacturing techniques, steel fire-rated frames can be formed from tubes, instead of hollow metal profiles, and shaped in an extrusion-like process similar to that of other advanced steel frames. This method allows for a wide range of narrow mullion profiles that feature well-defined corners and crisp edges. The result is improved sightlines, views, and smooth integration with neighboring window and curtain wall applications. Fire-rated frames can also be custom painted or powder-coated to complement non-fire-rated frames, including aluminum, stainless steel, and various color options.

Fire-rated frames are currently available with one- and two-hour ratings. They can provide fire protection (against the transfer of flames and smoke) or fire resistance (against flames, smoke, and heat transfer). Framing systems that provide fire resistance do so by resistive insulation. They are tested to ASTM E 119, Standard Methods for Fire Tests of Building Construction and Materials, and Underwriters Laboratories (UL) 263, Fire Resistance Ratings – meeting the fire resistance for walls. As a result, fire-rated frames are suitable for use in various applications, including:

- atriums

- stairwells

- interior separations

- storefronts

- along shallow lot lines

Conclusion

Through good design practices and routine upkeep, building teams can create modern steel curtain walls that are serviceable and attractive for many years to come. As Ludwig Mies van der Rohe said, “We must remember that everything depends on how we use a material, not on the material itself… Each material is only what we make it.”▪