The New York State Capitol, designed in various stages by a succession of architects including Leopold Eidlitz and H.H. Richardson, was built between 1869 and 1899. This landmark building illustrates both Second Empire and Richardsonian Romanesque elements and is an architectural masterpiece with ornate carved stone, vibrant paint finishes and decorative glass, and decorative tiled floors. A number of monumental public spaces such as the Senate and Assembly Chambers, and three monumental staircases (the Assembly, Senate, and Great Western Staircases) help to architecturally define the building. By the late 1990s, the building was losing its luster due to neglect, insensitive major modifications and chronic leakage, dating as far back as 1874, that damaged the exterior stone and interior finishes.

In 1996, the New York State Office of General Services (OGS) embarked upon a study to address the chronic leakage, which grew into a four-phase, 12-year restoration of the roofs and the three staircases, at a cost of approximately $85 million. This award winning project has finally addressed all of the reported leakage through the roofs, as well as restored to prominence the three monumental staircases by returning natural light and lost historic features to the spaces. This project’s success has also fostered other, separate restoration efforts within the Capitol that continue OGS’s efforts to restore the landmark to its original prominence.

Accomplishing this project took a team of consultants and contractors from the initial investigation in 1996 through construction in 2012. Success involved a partnership of OGS, contractors, and the design team to ensure quality and craftsmanship befitting this monumental building.

Figure 1: East elevation of the Capitol. Courtesy of Laurie Donald, Bernstein Associates Photographers, for OGS.

Architectural Terra Cotta Roofing

The Capitol has a complex roof arrangement, including several slate and clay tile roofs accented by architectural terra-cotta hips and railings (Figure 1). The original hung slate and clay tile roofing was replaced in the 1960s, incorporating decking and underlayment for added weather protection, but the terra-cotta was the original material dating to the late 1800s. These terra-cotta units were mortar set directly onto the shingled roofing and steel bar stock framing (Figure 2a), and were a source of ongoing leakage that deteriorated the terra-cotta and mortar setting beds and corroded supplemental steel anchors. Prior to this roof project, tiles had been face-fastened with through-anchors and covered with sealant in attempts to address the attachment and leakage concerns; these repairs exacerbated the leakage and resulted in further cracking and degradation of the terra-cotta. Full replacement was deemed necessary.

The replacement design required a water-tight system, with structurally sound attachments that maintained the original appearance and had durability comparable to the terra-cotta material (approximately 100 years). The design team elected to hang the new terra-cotta hip and apron tiles with stainless steel struts and attachment clips, which allowed for a drainable, water-tight copper flashing and continuous membrane underlayment below (Figure 2b). In order to attach these struts and provide a continuous substrate for the copper and membrane, the design included new steel framing and clips at each hip, ridge, and finial configuration to carry the terra-cotta loads back to the existing metal roof structure. The existing roof planes and framing on the Capitol varied significantly, so the design provided dimensional tolerances in the attachment system by use of the struts (allowing adjustability along the roof slope) and shims between the various attachment clips (allowing up/down adjustability). The individual terra-cotta tiles were also shimmed off the strut to accommodate variations in the tiles themselves. Finials and ridge tiles were set as more traditional stacked masonry with new stainless steel attachments.

Figure 2a and b: Original mortar-set terra cotta hip installation and new system with stainless steel strut attachments.

Pyramidal Granite Towers

The Capitol has four pyramidal masonry tower roofs, originally constructed with a granite exterior and a brick masonry vault backup. Chronic leakage plagued the rooms below these towers, which contained a combination of office space and rooms housing sensitive voting equipment and elevator machinery. A successful design solution needed to eliminate all leakage, while retaining the existing granite cladding, an integral part of the exterior appearance, and without relocating the equipment or machinery below.

During the initial field investigation, it was observed that each course of granite included a back cut in the stone to interlock successive courses. While helping to interlock the tower structurally, this back slope channeled water runoff into the granite bed joints, exacerbating mortar deterioration and leakage. This systemic issue accounted for the previous pointing and sealant repairs’ failure to provide long-term relief from the ongoing leakage.

The design team’s solution was to rebuild the pyramidal roofs as a typical masonry veneer, albeit on a monumental scale. Each pyramidal tower was deconstructed down to the cornice level and all granite units were salvaged, numbered, and stored for reinstallation. The towers were then rebuilt with a steel and precast pyramidal sub-structure on a reinforced-concrete ring beam designed to take the thrust of the new framing (Figure 3). New membrane and copper roofing, and through-wall flashing, were then installed for water management and the original granite was reinstalled with an open drainage cavity. The final appearance of the rebuilt tower exactly matched the original tower from the exterior.

Figure 3: Granite tower during installation of new substructure and after reinstallation of granite.

Assembly and Senate Staircase Restoration

Due to safety concerns during World War II, the skylights over the three monumental staircases were painted black. Ongoing leakage through the then dysfunctional skylights prompted their later removal and overclad with copper or slate roofing. In the late 1940s, space pressures within the Capitol prompted the State to infill the upper reaches of the Assembly and Senate Staircases with offices. These major modifications showed little regard for the staircases, as the designs were now out of fashion, and many of the staircases’ iconic features were removed or damaged including hand-blown, hand-painted glass laylights, carved stone features, and decorative paint finishes.

The roofing restoration work at the Capitol created an opportunity to replace the skylights over all three staircases and restore natural light to these remarkable public spaces. The Great Western Staircase was part of the first phase of construction. Work here included providing new modern aluminum framed skylights (including providing a new steel structure to support the side skylights where subsequent roof reconfigurations had removed the previous support framing), and restoring the glazing and paint on the original laylight frames that were still intact. The skylight and laylight were unveiled in August 2003.

The success of the Great Western Staircases’ restoration paved the way for the state Office of General Services to pursue restoration of the remaining two monumental staircases. These two staircases posed an even greater challenge, as their restoration required removal of the infill construction, which included connecting corridors, floors, and the design and installation of new laylights to replicate the long-since removed original laylight framing and glass.

Structural Concerns

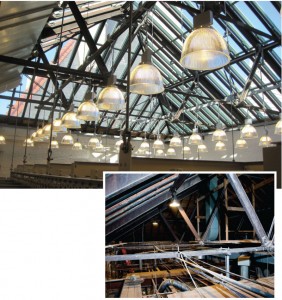

The staircases are constructed with load bearing masonry stairs and perimeter walls, and each is rectangular in plan with a long dimension of approximately 50 feet. The staircase roofs are constructed with long span iron trusses, perpendicular iron purlin members, and rafters which supported the original skylight glass but had since been modified to support wood decking and roofing. While there was little documentation of the original laylight framing grid pattern or attachment, the thick perimeter masonry walls are capped with a stone cornice that clearly supported the original laylight frame’s perimeter. Remnants of the original laylight framing hangers on the roof trusses were also identified. Using this information, the design team developed a gridded framing structure specific to each laylight that used the same methods of structural support as the original laylight frame (Figure 4).

Figure 4: Assembly Staircase attic before and after installation of new skylight, laylight, and staircase lighting. Before photo courtesy of Laurie Donald, Bernstein Associates Photographers, for OGS.

To meet building code requirements and contemporary performance expectations, the new laylight installation included an additional layer of laminated glass as safety glazing, and the replacement skylight was a contemporary aluminum-framed system with insulating glass units, attached to the existing structure. These necessary upgrades increased the dead load of both the laylight and roof/skylight systems, both of which are supported by the original iron roof trusses. Using historical material property data, initial analysis indicated that portions of the original Senate Staircase would be overstressed by the new laylight and skylight loads. Material testing, including tensile testing, chemical analysis, and Rockwell hardness testing provided quantified material properties that allowed the design team to refine the design and confirm that the trusses could be reused with minimal additional framing to redistribute the loads.

In addition to analysis of the new loads, the design considered the consequences of the load reductions resulting from the removal of the infill floor space. Portions of the Capitol already had reported settlement and foundation concerns due to the varved clay layer, and there were concerns that this load reduction could result in swelling of the clay that could cause damage to the existing masonry structure or interior finishes. Fortunately, in both staircases, the design team found that the infill construction represented a reasonably small percentage of the total staircase dead load, minimizing potential concerns.

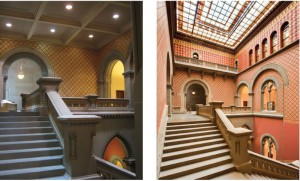

Figure 5: Assembly Staircase before and after restoration work. After photo courtesy of Laurie Donald, Bernstein Associates Photographers, for OGS.

Staircase Finish Work

The Assembly and Senate Staircases’ appearances are in stark contrast to each other. The Assembly Staircase is notable for its lavish, bright polychromatic painted plaster finishes, brightly colored laylight, and carved sandstone accents (Figure 5). Within the restored space, this staircase also included an ornately carved stone balcony and wood windows and doors looking into the space from the surrounding circulation areas. Unfortunately, all of these features, along with the laylight and skylight, were removed during the infill work. Restoring them required a careful preservation effort of documenting the painted-over colors and patterns; designing the new wood windows and doors based on remnants of the originals; replicating the detailed sandstone carvings that had been removed or damaged by the infill work; and designing a complimentary laylight based on limited original documentation.

Restoring the balcony required not only careful architectural detailing of the carved stonework, but a creative structural design, as it was no longer feasible to deeply embed the supporting stone brackets and floor into the load bearing walls (as was done in the original design). The project design instead utilized a horizontal steel truss fastened to the surrounding masonry walls to support a sandstone stone cladding that mimicked the bracket and floor slab appearance (Figure 6). The stone railing was similarly reinforced with steel posts that were clad with sandstone.

Figure 6: Balcony steel frame and sandstone cladding installation during construction. Courtesy of Laurie Donald, Bernstein Associates Photographers, for OGS.

In contrast to the lavishly colored Assembly Staircase, the Senate Staircase is monochromatic and constructed with extensively carved red sandstone and capped with an opalescent glass laylight above (Figure 7). Similar to the Assembly Staircase, careful preservation efforts were required to replicate the damaged, intricately carved stone finishes and to clean the exposed stone of both general soiling and of mastics, markings, and staining left behind by the infill construction.

Figure 7: Senate Staircase before and after restoration work. After photo courtesy of Laurie Donald, Bernstein Associates Photographers,

for OGS.

The Assembly Staircase restoration was unveiled in January 2012. The Senate Staircase restoration, the final portion of the project, was unveiled by Governor Andrew Cuomo in January 2013.▪