Over the last two decades, the practice of delegating the design of structural steel connections and structural steel stairs to an engineer retained by the steel fabricator has grown more and more popular. As such, the execution of these projects has seen many different methods to get to a final design and fabricated steel. This article is intended to provide some history into delegated design, a review of the documents that define standard practice, and some strategies and best practices for specifying delegated design.

History of Delegated Design

Delegated design was originally developed to provide a more efficient project for the owner. By allowing steel fabricators and steel erectors some degree of leeway in the way the steel frame and stairs are constructed, they can leverage their expertise, experience, and particular equipment to maximize both cost and schedule savings. Fabricators are allowed to select connections based on the most efficient fabrication methods for their shop. Erectors are able to influence the construction sequence to minimize constructability issues and provide shorter schedules. The overarching intent is to produce the most economical structure possible with the shortest construction schedule to maximize the project owner’s return.

The Engineer of Record (EoR) takes every opportunity to make the project successful for the project owner, and a well-executed delegated design does just that. However, when bad practices are introduced into the project, delegated design can negatively impact both the cost and construction schedule of the steel package.

Importance of Early Decisions

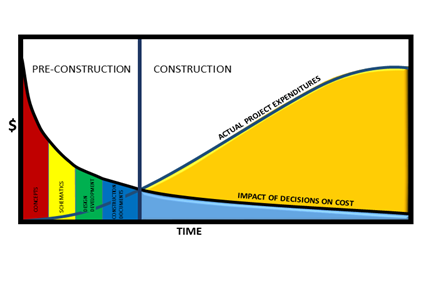

One way that delegated design projects can have negative issues is when critical decisions are postponed to construction phase as opposed to being made during design. Figure 1 shows that the impact of good planning and strategies are greater early in the project where the cost of delays and issues is much greater during construction. The EoR can help a project significantly by identifying decisions and coordination items that need to be made during design.

Standard Practices

The American Institute of Steel Construction (AISC) has made many advances in standardizing how delegated design is executed. This can be seen in the most recent edition of the Code of Standard Practice (CoSP). The ANSI/AISC 303-22 Code of Standard Practice for Steel Buildings and Bridges incorporates changes to better suit projects with delegated design.

Chapter 3 of the CoSP outlines the expectations and requirements for Design Documents and Specifications on delegated design projects.

It is important to note that delegated design is not a requirement. The CoSP has three options for how connections are specified; Section 3.2.3 of the CoSP, titled “Requirements for Connection,” outlines these three methods. The method by which the connections shall be designed will be selected and specified by the owner’s designated representative for design (ODRD) and is typically the EoR. The methods are summarized below:

- The complete connection design shall be shown in the structural design documents.

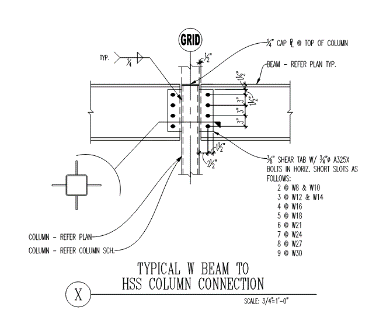

- The connections shall be designated in the structural design documents in such a way that an experienced detailer can complete the connection design. An example of a steel connection detail using Method 2 is shown in Figure 2.

- The connection shall be designated in the structural design documents or specifications to be designed by a licensed engineer working for the fabricator. This method is often referred to as “delegated design.”

Section 3.2.3 (3) of the CoSP outlines the requirements of how delegated design shall be specified and executed. Since, on most projects, the CoSP is referenced as a specification that shall be followed in the structural design documents, most steel fabricators, detailers, and steel erectors expect these provisions to be followed. In the absence of information to the contrary, most fabricators, detailers, and steel erectors will assume that they must follow the CoSP and will bid on the project accordingly. For this reason, any EoR that specifies projects with delegated design should become familiar with the CoSP section 3.2.3 and, when necessary, make sure any deviations from the CoSP are clearly defined in the structural design documents.

Listed below is a brief summary of the provisions in the CoSP:

- 3.2.3 (3) (a) Requires Substantial connection information. This is an important addition to the 2022 CoSP. Substantiating connection information is the documents that are prepared by the engineer designing the connections for the fabricator. The Substantiating Information is the documents that the EoR will review. It can also include plans and detailed diagrams depicting the structural connections.

- 3.2.3 (3) (b) The fabricator (and, in turn, the connection engineer) shall submit in a timely manner representative examples of the substantiating connection information. This provision is intended to have all team members agree on the format for the substantiating connection information prior to the preparation of the calculations and design drawings. This step is intended to facilitate a fast and more efficient approval process.

- 3.2.3 (3) (c) Requires the connection engineer to review the shop drawings and confirm in writing that the shop drawings properly incorporate the connection design. It is important to note that the CoSP does not require the connection engineer to stamp the shop drawings. In fact, the CoSP commentary discourages the practice. This provision also clearly states that approval of the shop drawings by the connection engineer does not replace the approval process of the EoR.

- 3.2.4 States that all member reinforcement, including stiffeners, web doublers, plates, and bearing stiffeners located away from the connection, shall be designed by the EoR and shown in sufficient detail.

Section 3.2.3 of the CoSP also has the following requirements for the structural design documents:

- The EoR shall provide project-specific details that show the conceptual configuration for the order of magnitude of the forces to be transmitted. This provision is intended to provide the fabricator and the erector sufficient information to accurately bid on the project with the need to retain an engineer during the bidding process. It is unreasonable and counterproductive to expect fabricators to spend money on a connection engineer for projects they have not been awarded. It benefits everyone involved in a project when the structural design documents are complete enough to price a project accurately.

- The EoR shall specify any restrictions on the connection in the structural design documents. This can include the type of bolts used, connection types that cannot be used, and the grade of connection materials.

- The loads, including transfer forces, shall be provided in such a way as to facilitate the connection design.

- The EoR shall clearly state whether the loads provided are service or factored loads and whether ASD or LRFD shall be used in the calculations for the connection design.

- Substantiating information is required to be included in the approval documents.

To help with structural steel projects with stairs, AISC has published Design Guide 34: Steel-Framed Stairway Design. Chapter 9 of Design Guide 34 specifically addresses the Delegated Design of Stairs. This chapter outlines the responsibilities of the EoR, the architect, and the stair design engineer. It clearly states that the stair design engineer is typically not the most knowledgeable about egress and building requirements with respect to stairs. For this reason, the Design Guide recommends that the architect provide sufficient details for the geometry of the stairs to be determined. The Design Guide also recommends that the EoR provide details for how the stair shall attached to the main frame, details, and dimensions for the slab openings.

In addition to outlining the various roles of a stair design project, Design Guide 34 provides a designer checklist in Appendix A. This checklist is a great tool for helping in the preparation of both architectural and structural documents associated with delegated stair design.

The Council of American Structural Engineers (CASE) has developed many useful documents that assist with the preparation of design documents. Three of the documents that CASE published are listed below:

- 962 – National Practice Guidelines for Structural Engineers of Records

- 962-B Practice Guidelines for Specialty Structural Engineers

- 962-D a Guideline Addressing Coordination and Completeness of Structural Construction Documents

962—National Practice Guidelines for Structural Engineer of Record has multiple provisions. Some that pertain directly to delegated design include maintaining responsibility for the primary structure with the EoR. This means that, ultimately, the EoR is responsible for the structural integrity of the project. This guide also puts the responsibility of communicating the project requirements on the EoR. The submittal review process and responsibilities during that process are also defined in this guideline.

962—National Practice Guidelines for Specialty Structural Engineers. This guideline is intended for all engineers who do delegated design, including Pre-Engineered Metal Building Engineers, Joist Engineers, and Pre-Cast Concrete Engineers. Despite being all-encompassing, it has some good recommendations that can apply to delegated connection and stair design. It requires the connection engineer to meet the qualifications outlined in the structural design documents. The connection engineer is required to request information or clarification when necessary. The connection engineer shall notify the EoR of perceived errors in the structural design documents. Still, the connection engineer is not responsible for conducting a peer review of the structural design documents.

962-D—A Guideline Addressing the Coordination and Completeness of Structural Construction Documents provides industry standards for what should be included in structural design documents. It also provides recommendations for how design criteria shall be communicated.

Strategies for Successful Delegated Design

The following are strategies the author has developed to help make delegated design projects run more efficiently. It is important to remember that the ultimate goal of delegated design is to increase the return on investment of the project for the project owner by providing a more economical design and a faster construction process. These strategies are intended to do just that.

Strategy 1: Make the Process Collaborative

Delegated design was developed to leverage the expertise of the fabricator, erector, detailer, and specialty engineers to make the project better. EoRs who specify delegated design should go into the process open-minded and willing to let these other members of the team play a part in the design. When all team members contribute, the project is better and runs more smoothly.

Strategy 2: Provide Accurate Reactions

Too often, EoRs use widely conservative blanket specifications for how the beam reactions are to be calculated. These include such provisions as 55% of the Uniform Load Tables, the full shear capacity of the beam, or tables with conservative loads.

None of these methods are as effective as showing the actual reactions for each beam on the drawings. As stated previously, the ultimate goal of delegated design is to make the project more efficient. That is impossible to do when the connections are being designed for wildly conservative end reactions. When accurate reactions are provided, the connections are designed to be sufficient for the loads that the beam will see in its lifetime.

Also, loads that are shown as dead, live, wind, and seismic separately allow for load reductions to be taken into account per the ASCE 7 load cases. For example, when a connection engineer is designing a beam-to-column connection with a wind transfer force and the dead and live load reactions are provided separately, the connection engineer can reduce the live load per the ASCE 7 load cases. When the reactions are not shown separately, the connection will be designed for the full live load in excess of code requirements.

Strategy 3: Make the Project Easy to Bid

CoSP requires the EoR to provide sufficient information in the structural design documents for the fabricator and erector to bid on the project accurately. The structural design documents should provide some depiction of all connections that are appropriate to the magnitude of the forces that are being transmitted. The depiction should also show stiffener and doubler plates that may be required. During the preparation of the approval documents, the fabricator and erector can develop the actual connection geometry in conjunction with the connection engineer. By providing sufficient information to bid on the project, the EoR avoids costly and time-wasting confrontations associated with change orders, and they are helping ensure that the bidding process is as competitive as possible.

Strategy 4: Use Substantiating Documents

The structural design documents should require the submission of substantiating documents. The EoR should also clearly define their expectations for the substantiating documents. Substantiating documents are the best method to clearly communicate the connection and/or stair design to the EoR as well as the detailer.

Substantiating documents also avoids a common point of confusion: whether or not the connection/stair engineer should sign and seal the shop drawings. Since only portions of the shop drawings reflect the connection/stair engineer’s work, having them sign and seal documents that contain more than just their work can be problematic.

First, it causes an insurance issue. There are examples where connection engineers have signed and sealed shop drawings with errors that were not the connection engineer’s fault, yet they were still held liable. It also causes issues with many state engineering acts, which require engineers to only sign and seal documents prepared under their direct supervision.

The practices outlined by the CoSP for the use of substantiating documents and the connection engineer providing written confirmation that they have reviewed the shop drawings alleviate the need for the connection engineer to sign and seal the shop drawings. This avoids multiple legal entanglements.

Strategy 5: Clearly Define Expectations for Submittals

The earlier in the project, the fabricator, erector, detailer, and specialty engineer understand the expectations of the EoR for review of the approval documents, the faster and better the approval documents can be prepared.

Special requirements, such as the format for substantiating documents, connection design criteria, connections that can or cannot be used, or material specifications, should be clearly specified in the structural design documents.

Strategy 6: Manage the Architect’s Expectations

This strategy primarily pertains to stairs and architecturally exposed structural steel. It is important during the design process that the EoR ensures the architect’s expectations are achievable. This can be as simple as giving the architect an estimate of stringer size for ornamental stair or bolt counts and weld sizes for exposed connections. Too often, submittals are delayed because the architect’s vision simply isn’t feasible for the project. Clear communication between the EoR and the architect before the project is released for bid can avoid confusion.

Delegated design under the right circumstances can benefit all parties involved in the design, fabrication, and erection of structural steel and stairs. The project starts with the EoR. As such, the EoR and how they specify the project can have the greatest impact on how well the project goes. All engineers who specify delegated design should strive to make their structural design documents as concise and easy to use as possible.■