Designing for South Florida’s harsh environmental conditions.

Aluminum is a widely used building material due to its versatility, malleability, high resistance to corrosion, and high strength-to-weight ratio. Aluminum products come in many shapes and forms. Despite its greater strength-to-weight ratio, aluminum is generally weaker and more flexible than steel. While steel remains the favorable metal for the main load-carrying structure in buildings, aluminum is the first choice for building components or building-like structures such as, cladding and roofing panels, shade structures, window and door frames, balcony guardrails, space trusses, and tanks. Aluminum is also used in highway and bridge light poles, signs, and rails.

In south Florida, buildings are threatened by high temperatures, frequent rains, sunlight exposure, strong winds, and salt-spray from the ocean creating harsher environmental conditions throughout the year than most parts of the country. Due to its physical and mechanical properties, as discussed later, aluminum is an economical material choice and often the most cost-effective alternative to steel in the south Florida market.

Available Material Grades

Aluminum is used for structural applications in the form of alloys, which are obtained by combining aluminum with at least another chemical element. Typically, the alloying elements are a small percentage of the compound weight. Structural shapes and thin plates used for manufacturing products in building construction are made of wrought aluminum. Wrought aluminum is made by extrusion, rolling, or forging, and can be classified into seven series, each designated by a four-digit number (1000 through 8000). Sheets and plates used in roofing and cladding systems are often made of the 3000 series alloys. In these alloys, the main alloying element is manganese, which provides corrosion resistance and allows the material to be rolled easily. However, the 3000 series alloys offer limited strength.

The 6000 series alloys are primarily used to produce structural shapes. In these alloys, the main alloying elements are magnesium and silicon. These alloys are strong, resistant to corrosion and easily extrudable, but lose strength when welded. Aluminum alloys can be tempered to increase their strength. Tempering can be done by heat treatments or strain hardening. The 6000 series alloys are tempered by heat treatment, while the 3000 series alloys are tempered by strain hardening. Tempering is designated by the letter “T” for heat treatments and “H” for strain hardening. Differences in the tempering process are identified by a digit following the letter designation, such as T1 through T6 or H1 though H4. The side effect of tempering is a reduction in ductility. Cast aluminum alloys are generally classified into two groups based on the selected manufacturing process, which can be sand casting or permanent mold casting.

Design Basis

In the United States, aluminum shapes for building construction must comply with the Specification for Aluminum Structures, which is included in the Aluminum Design Manual (ADM) published by the Aluminum Association (2020). The minimum strength requirements for aluminum shapes are standardized by the American Society for Testing and Materials (ASTM).

Strength

The strength design of aluminum is very similar to that for steel. Aluminum structures can be designed based on the Load and Resistance Factor Design (LRFD) or the Allowable Stress Design (ASD). While aluminum members subjected to flexure, axial, and/or shear loads exhibit similar failure mechanisms as their steel counterparts, the design formulae are different and more rigorous. ADM sets the modulus of elasticity of aluminum equal to 10,100 ksi (approximately 2.9 times lower than that of steel) for all alloy-temper combinations. ADM provides minimum ultimate and yield tensile strengths for aluminum products made of various alloy-temper combinations and that comply with the ASTM specifications.

For identical flexural designs, when compared with steel sections, aluminum shapes are expected to be deeper to reduce stresses and are expected to have shorter unbraced lengths to meet buckling limit states. The ultimate and yield tensile strengths of aluminum alloys are significantly dependent on the alloy-temper combinations. A small variation of tempering results in significant changes in mechanical properties.

For example, standard structural proles that are made of wrought aluminum 6061-T6 (i.e., the alloy series and the temper designation, respectively) and that comply with ASTM B308, have design ultimate and yield tensile strengths of 38 and 35 ksi, respectively. Instead, the design ultimate and yield tensile strengths are 22 and 16 ksi, respectively, for the 6063-T5 alloy. Both are commonly used.

The mechanical properties of aluminum alloys are inert to temperatures up to approximately 200F as reported by ADM. At higher temperatures, the strength of the aluminum part reduces depending on alloy, temper, temperature, and time of exposure. The reduction of strength (relative to the strength at room temperature) is greater for aluminum than steel in case of a re. Thus, aluminum members need a more robust insulation than steel members to resist the effects of fire. Fire protection can be achieved using, for example, plaster boards when required. Fire performance-based design is allowed by ADM.

Aluminum shapes can be welded or fastened together. The ultimate and yield strengths of the 6000 series alloys are significantly reduced by welding. The weld-affected zone typically extends up to approximately 1-in. on either side of the weld centerline. ADM publishes welded strengths of available alloy-temper combinations for welds complying with the American Welding Society (AWS) specifications D1.2. The filler used in welded joints is typically of the same chemical composition of the main alloy. Aluminum bolts, nuts and washers are typically made from 2024-T4, 6061-T6, or 7075-T73 alloys. The main advantage of using aluminum bolts to connect aluminum parts is that it virtually eliminates the risk of galvanic corrosion. However, the reduced strength of aluminum alloy bolts as compared to steel bolts makes their use impractical in most applications. Therefore, steel or stainless-steel bolts are often the preferred option when bolting together aluminum parts. High-strength fasteners, such as ASTM A490 bolts, should not be used in contact with aluminum due to the risk of hydrogen embrittlement and galvanic action in exterior applications.

The design of aluminum structures is commonly performed through delegated design. The as-designed alloys are specified in the shop drawing submittals and verified in the eld by reviewing the fabricator’s documentation. When project data are lacking, the determination of the as-built alloy-temper combination is a challenging task. However, in some cases, it could be estimated through the Vickers Hardness tests (ASTM E384, Standard Test Method for Microindentation Hardness of Materials) performed on material samples extracted from the structural member in question.

Serviceability

Due to the lower modulus of elasticity, which has been previously mentioned, aluminum beams are also expected to be deeper than steel beams to meet code-level deflection requirements. The reduced modulus paired with the lower material density makes aluminum members more susceptible to pedestrian- and/ or wind-induced vibrations than their steel counterparts. When compared to steel, the lower modulus of elasticity makes aluminum members more prone to wind-induced instabilities, such as, vortex shedding. Furthermore, depending on the structure’s design service life, the fatigue strength of aluminum joints is expected to be approximately one-third to one-half that of steel for the same joint detail. Although these characteristics of aluminum alloys can be considered unfavorable, practicing engineers are able to design within their limitations to take advantage of their benefits, such as on lighter weight cladding and roofing panel systems.

Durability

Aluminum resists corrosion due to its so-called “self-healing” behavior. When bare aluminum is exposed to oxygen, a lm of aluminum oxide forms on the surface of the metal and protects it against corrosion. The 3000 and 6000 series alloys have good corrosion resistance and could be used without protection. However, most building codes do require protection due to contact with dissimilar materials and continued exposure to moisture and other corrosive agents.

Aluminum in contact with another metal often results in galvanic corrosion (Fontana and Greene, 1983, and Francis, 2017). This is an electrochemical reaction that occurs when two different metals are joined in the presence of a conductive fluid, such as water. In most galvanic couples that involve a ferrous metal (which contains iron), aluminum will experience galvanic corrosion. On the contrary, aluminum in contact with, for example, magnesium, zinc, cadmium, and passive stainless steel does not experience galvanic corrosion in most environments.

The alkaline environment of cement-based products protects embedded steel from corrosion. Differently from steel, the passive oxide film that is normally present on the aluminum surface in neutral environments is destroyed in highly alkaline environments. This reaction occurs when the cementitious materials are in direct contact with the aluminum and water is present. The worst effects occur when fresh concrete is in direct contact to bare aluminum. In the case of cured concrete, water can be present due to the excess of mixing water or from wetting during concrete placement for instance. To compound the issue of a deteriorating aluminum surface, dissimilar metals can be embedded in cementitious materials, either placed in direct contact or near each other. Additionally, chlorides accelerate the corrosion process. In coastal environments, the corrosion process can be particularly accelerated due to the proximity of salt water or wind-driven airborne salt sprays.

Case Studies of Aluminum Balcony Guardrails in South Florida

The design of balcony guardrails may seem to be a simple task at first sight. If the guardrail system is made of aluminum and the project location is in south Florida, this statement may not be true. The following sections will discuss an overview of most issues found in the design of aluminum guardrail systems when assessing the performance of aluminum structures.

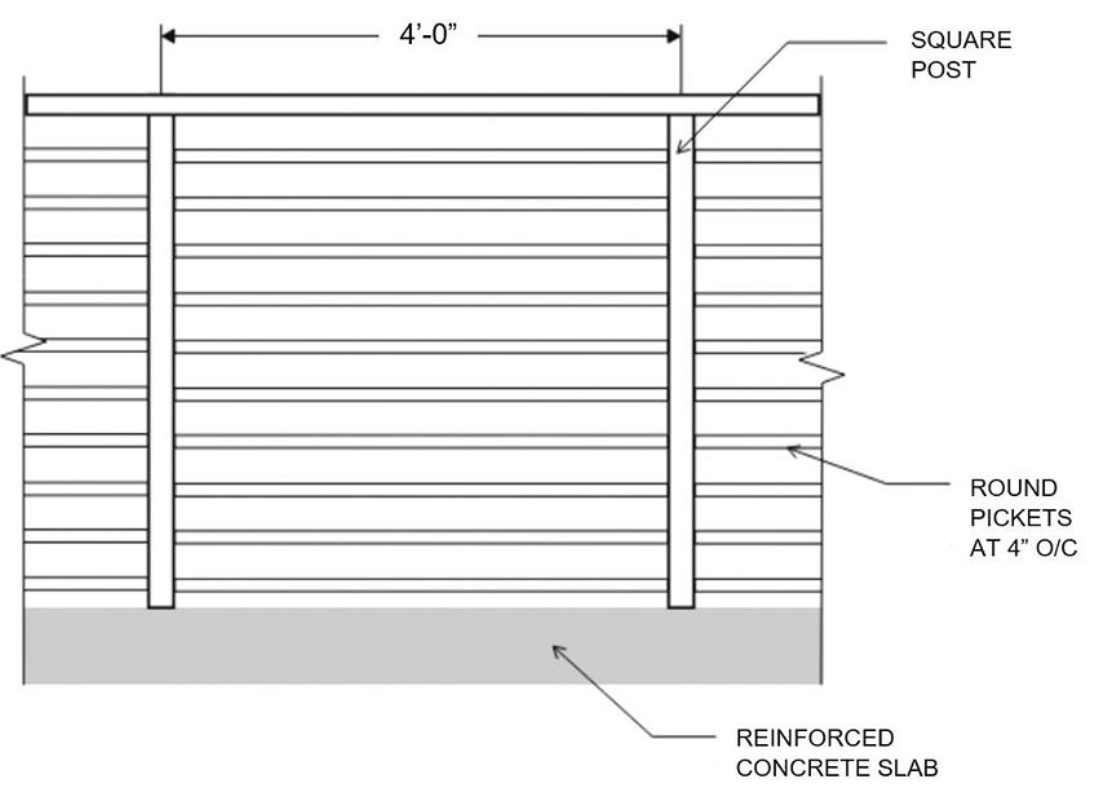

Balcony guardrails are often built out of slender aluminum extruded shapes due to their cost effectiveness, ease of fabrication and durability. The guardrail design configuration shown in Figure 1 requires special attention. As shown in the figure, the vertical posts are made of extruded aluminum square shapes spaced at 4-feet on center. The horizontal pickets are made of extruded aluminum circular shapes, are vertically spaced at 4-inches on center (to meet code requirements), and their ends are fillet-welded to the post faces. The following design considerations are unique to aluminum.

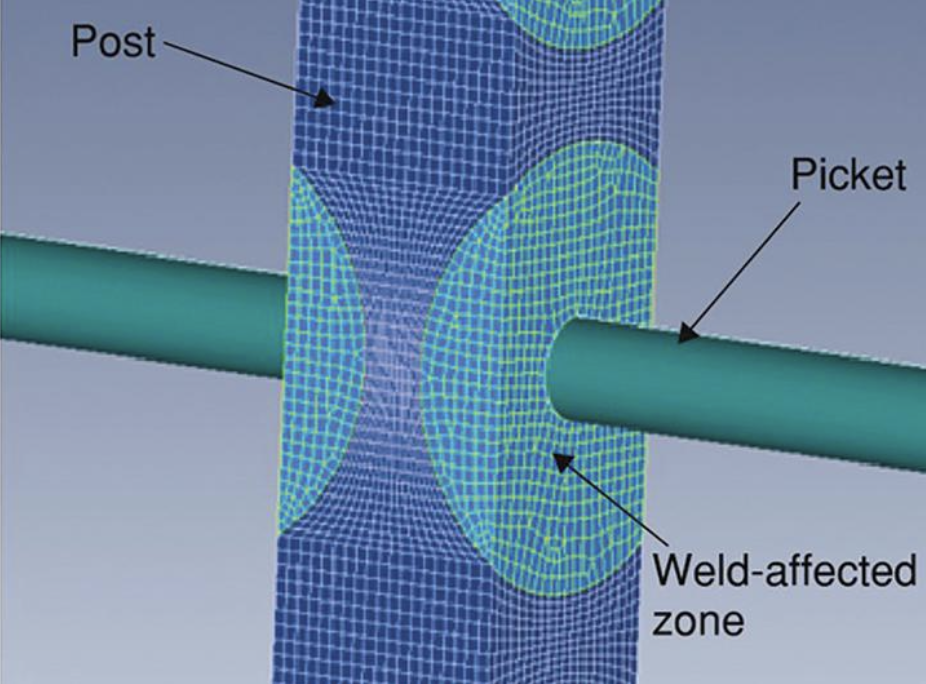

- The first design consideration is related to the effects of welding to the strength of the vertical posts. As mentioned above, the heat produced by welding operations causes a significant reduction of the welded material’s tensile strength within a narrow band (approximately 1.0 in.) on either side of the weld. The flexural capacity of the post must be assessed by considering the extent of the weld-induced heat-affected zone at the post-to-picket joints. For example, aluminum 6063-T5 has a welded nominal yield tensile strength of 8 ksi when compared to the 16-ksi unwelded strength. e strength calculations can be simplified by assigning the welded yield strength to the material comprised within the heat-affected zone and the unwelded strength to the material outside of it (Figure 2). For condition assessment, when the as-built strength of a structural member with welded joints is in question, eld load testing is a useful tool to assess the existing load-carrying capacity (Section 1708 of the 2021 International Building Code).

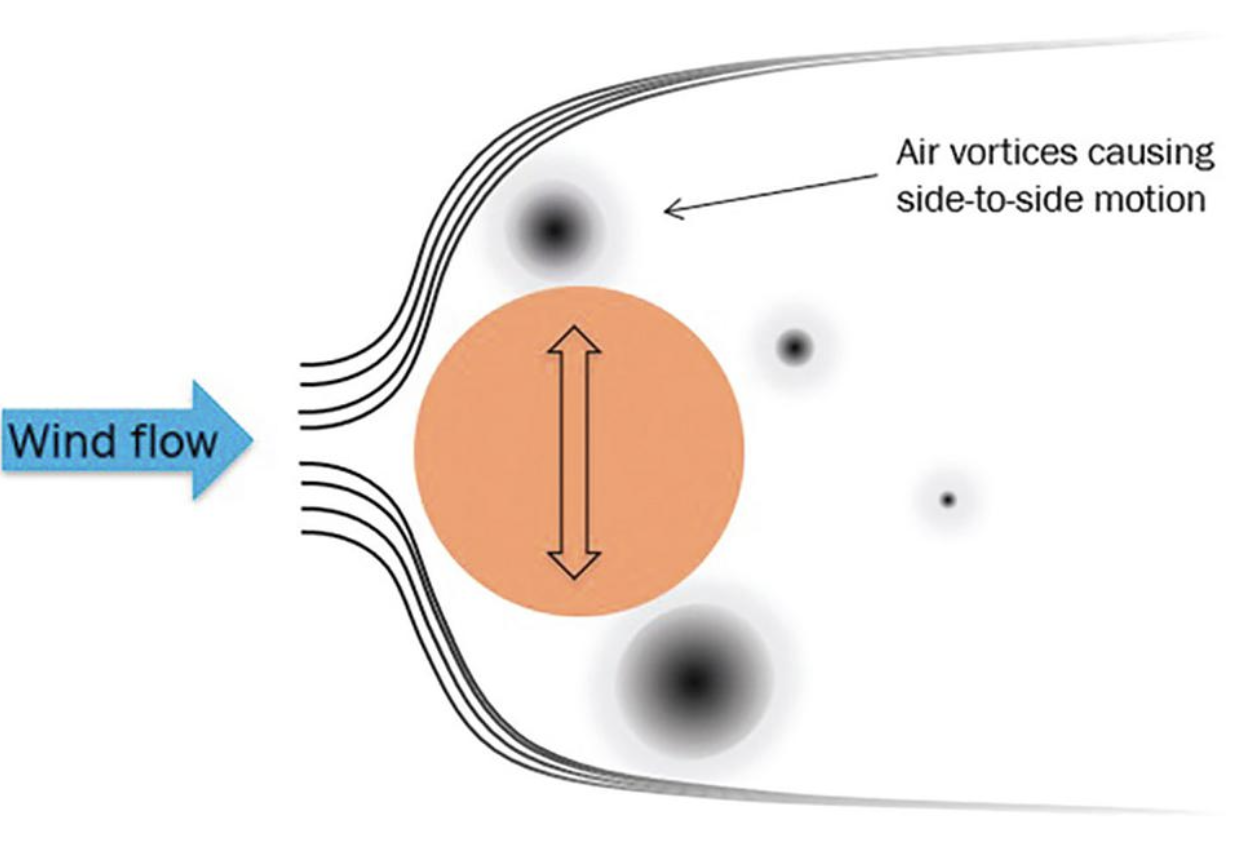

- A second design consideration is related to the sensitivity of the horizontal pickets to wind-induced instabilities. Vortex shedding of the horizontal pickets can occur at low return period wind speeds. It is not uncommon for this to occur in coastal structures due to low, but steady prevailing winds. The induced across-wind vibrations of the pickets may, in turn, generate a humming sound that can be annoying to the building occupants. For example, 3/4-inch diameter cylindrical shapes may be a practical and economical solution for the pickets. While they are adequate to sustain the static design loads, their performance due to dynamic loads, such as wind, needs to be further studied. The pickets can be analyzed as fixed-fixed beams due to the circular fillet weld at the post joints. The natural frequency of the first flexural mode of the fixed-fixed picket is calculated to be approximately 52 Hz (assuming a picket wall thickness of approximately 1/16-inch and a length of approximately 48-in.). Assuming a Strouhal number for circular sections of 0.2 per ADM (or 0.18 per Holmes, 2001), hand calculations show that a wind speed of approximately 12 mph would be enough to activate the pickets first flexural mode. The Strouhal number is a dimensionless number (equal to the ratio between the vortex shedding frequency times the characteristic length of the object and the ow velocity) that can be used to predict the wind velocity causing vortex-shedding-induced vibrations in an object. This means that air vortices form around the pickets at wind speeds of approximately 12 mph causing the pickets to oscillate harmonically up and down (Figure 3). Welded structural members have low damping (typically ranging between 0.2 and 0.5%). Assuming a damping ratio of 0.5%, for example, it would take approximately less than 2 seconds for the picket to reach steady-state, resonant vibrations. 12-mph winds are frequent in South Florida. It is good practice to avoid resonant effects at low wind speeds. In addition, depending on the magnitude of the applied cyclic stresses, the wind-induced vibrations may lead to the fatigue failure of the welded picket-to-post joint, thus compromising the structural integrity of the guardrail system. At resonance, the maximum dynamic effects on the picket are expected to be (depending on the system’s damping) one or two orders of magnitude greater than the corresponding equivalent static wind effects. The structural elements should, therefore, be designed so that their natural frequency is either much greater or much lower than the frequency of the applied loading. The ADM-based fatigue design is similar to the one established by AISC for steel structures.

- The third design consideration is related to the durability of the guardrail posts in direct contact with the balcony slab concrete. In south Florida, glass railing in-fill panels are often utilized, thus causing high bending forces at the post bases. A typical design has the guardrail posts embedded in the concrete slab due to the high bending forces. The aluminum post is, therefore, in direct contact with concrete on all sides. As mentioned above, the alkalinity of the concrete corrodes the bare aluminum. The corrosion rate is increased by the presence of chloride ions, which are common in coastal regions. Nowadays, extruded aluminum shapes for exterior applications are often coated with organic coatings. These coatings are tested to protect aluminum from corrosive environments as established by the Architectural Aluminum Manufacturers Association (AAMA) requirements, which are considered the highest industry standards of performance for organic coatings on aluminum extrusions. While they can protect aluminum against most aggressive environments, organic coatings can easily be scratched in the eld during transportation or installation, thus exposing the bare aluminum to the environment. ADM species that aluminum surfaces in contact or embedded in concrete, that do not remain dry after curing, shall be coated with a zinc molybdate primer or an alkali resistant bituminous paint (Figure 4). Zinc molybdates are corrosion inhibitors and are used as additives in coatings. Bituminous paints offer waterproofing and corrosion resistant properties.

of the vortices is separated from the natural frequency of the picket, the picket oscillates up and down, with small amplitudes, at the frequency of the vortices. If the two frequencies are sufficiently close to each other (or synchronized), the picket’s natural frequency is activated. The result of this resonance is a humming sound that can be felt as uncomfortable to the building occupants.

The use of surface-mounted systems with post-installed fasteners can be an effective alternative for railing systems without glass panels in either new construction or for remedial applications. As discussed above, aluminum in contact with dissimilar metals may result in galvanic corrosion. While aluminum fasteners may be the obvious solution, their shear and tensile strengths are limited. Steel fasteners (black, coated, or galvanized) must be avoided at all costs. When aluminum is in contact with steel, the galvanic corrosion results in a movement of electrons from the steel fastener to the aluminum connecting plate. This phenomenon leads to the section loss of the fastener, thus decreasing the capacity of the connection. Stainless steel fasteners must be used instead. While the contact between aluminum and stainless steel is safe (aluminum and stainless steel are close to each other in the Galvanic chart), in corrosive environments bond breaker tapes between the fasteners and the aluminum connecting plate are recommended. Aluminum coating failures including bubbling, flaking, and/or chalky paint texture may be observed due to the lack of separation between the two materials.

Figures 5 and 6 illustrate examples of corrosion in aluminum guardrail post applications due to contact with cementitious materials and dissimilar metals, respectively. Figure 7 shows other examples of aluminum corrosion due to direct contact with stucco and stainless-steel.

Conclusions

Aluminum structures are becoming more and more competitive in harsh environments due to their extended service life, as opposed to steel. Most structural engineers are comfortable in designing with steel. Although aluminum design has similarities with steel, it has several unique characteristics that should be fully understood by the designer.

References

Aluminum Design Manual, Aluminum Association, 2020.

Fontana, Mars G., and Norbert D. Greene. Corrosion Engineering. McGraw-Hill, 1983.

Francis, Roger. Galvanic Corrosion: A Practical Guide for Engineers, 2nd Edition. NACE, 2017

Holmes, John. Wind Loading of Structures. CRC Press, 2001.