The National Council of Structural Engineers Associations (NCSEA) is pleased to publish the 2023 Excellence in Structural Engineering (SEE) Awards winners. The awards were announced during NCSEA’s Structural Engineering Summit, held November 7-10, 2023, at the Disneyland Hotel in Anaheim, California. A video of the awards presentation can be found on the NCSEA website. The winning entries recognize the most innovative and groundbreaking work of our profession’s top talents. Learn More About This Year’s Winners.

The 2023 Awards Committee was chaired by Carrie Johnson (Wallace Design Collective, PC, Tulsa, OK). Ms. Johnson noted: “The judging was conducted in two rounds. The first round was performed by a group of NCSEA Past Presidents and the second round was completed in Portland by members of the Structural Engineers Association of Oregon (SEAO). The judges were truly impressed by the quality, innovation, and creativity of the award submissions.”

The judges selected the winning projects based on the following criteria:

- Complexity of criteria or unique problems

- Creativity of structural design

- Innovative application of new or existing materials or techniques

- Commitment to sustainability through efficient use of materials, resilience, circular economy principles, or embodied carbon reduction

- Ingenuity of design for constructability challenges and efficient use of labor

Awards were given in eight categories, with an Outstanding Project awarded in each of the following categories:

- New Buildings under $30 Million

- New Buildings $30 Million to $80 Million

- New Buildings $80 Million to $200 Million

- New Buildings over $200 Million

- New Bridges and Transportation Structures

- Forensic | Renovation | Retrofit | Rehabilitation Structures under $20 Million

- Forensic | Renovation | Retrofit | Rehabilitation Structures over $20 Million

- Other Structures

After the judging was complete in each category, an overall 2023 Structure of the Year award was selected from the eight Outstanding Projects. This resulted in a lively discussion among the judges who compared each project based on the complexities and ingenuity required.

Congratulations to the 2023 SEE Award winners! Keep an eye out for in-depth articles on several of the 2023 winners in future issues of STRUCTURE.

The judging was conducted in two rounds. The judges were truly impressed by the quality, innovation, and creativity of the award submissions.

Carrie Johnson, P. E., S. E., Chair, 2023 Awards Committee

2023 Panel of Judges

Round 1: Past Presidents

Vicki Arbitrio, P. E., Gilsanz Murray Steficek

Barry Arnold, ARW (retired)

Craig Barnes, Socotec

Marc Barter, Barter & Associates

Bill Bast, S. E., Socotec

Jim Cagley, Cagley & Associates

Tom DiBlasi, DiBlasi & Associates

Tom Grogan, Haskell/Retired

Emily Guglielmo, Martin/Martin

Carrie Johnson, P. E., Wallace Design Collective

Jim Malley, Degenkolb

Ben Nelson, P. E., Martin/Martin

Ed Quesenberry, Equilibrium

Sanjeev Shah, SSI Consulting

Round 2: Structural Engineering Association of Oregon

Damian Andreani, Catena

Mike Astrella, Catena

Peder Golberg, James G. Pierson, Inc.

Tom Grogan, Haskell (retired)

Kylean Gunhus, Miller

Carrie Johnson, Wallace Design Collective

Amit Kumar, City of Portland

Nisarg Mehta, DCI

Ben Nelson, Martin/Martin

Ed Quesenberry, Equilibrium

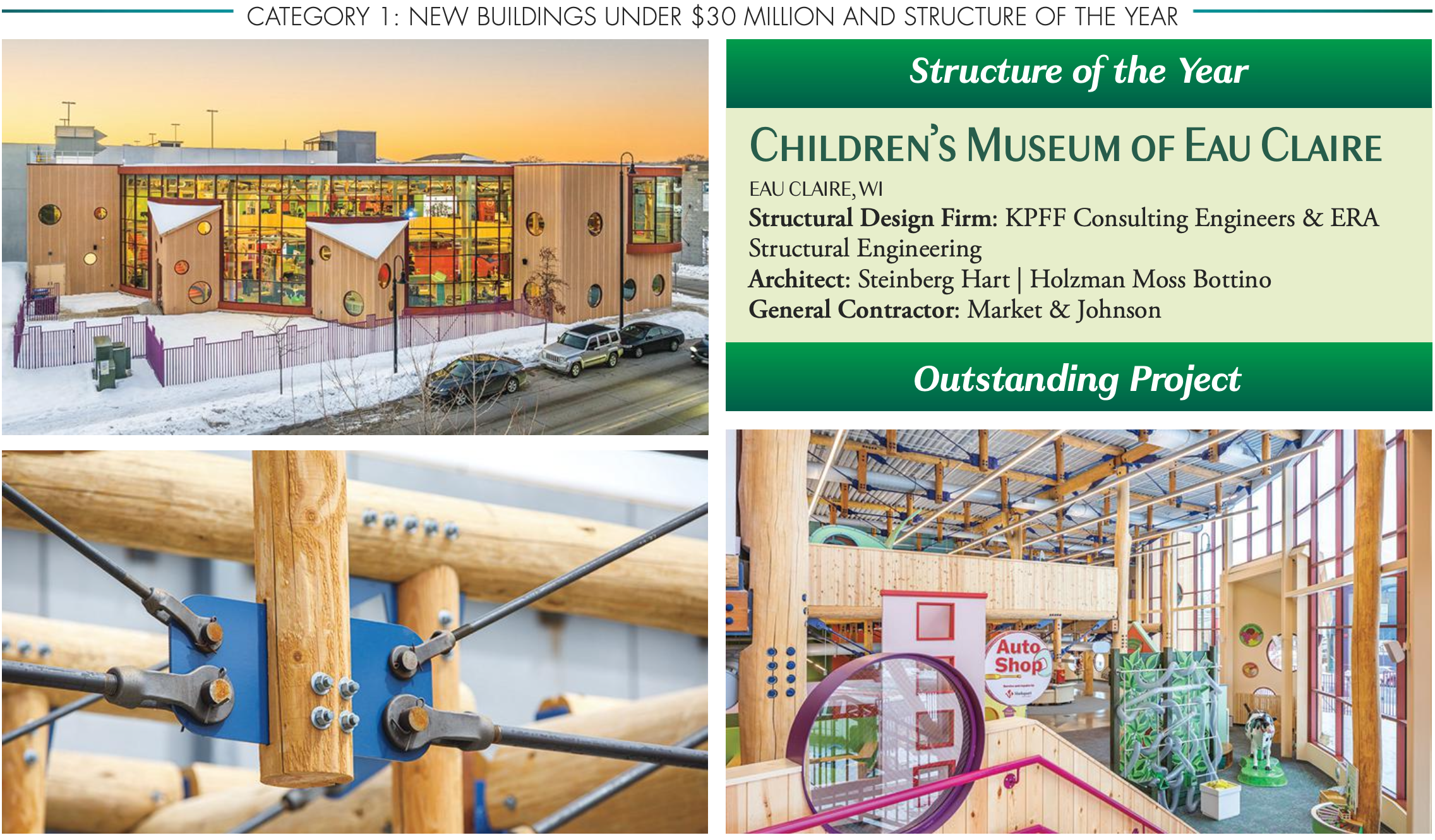

SRT Design Offers Resilient and Cost-Effective Solution

Creating a 26,000-square-foot biophilic structure using structural round timber (SRT) required creativity. Using non-milled whole ash and sugar maple trees, the childrens’ museum design featured two stories: the bottom story of SRT supported a 5.5-inch thick concrete slab, topped by the second story of SRT, using the trees’ branches to hold up the building’s roof trusses. The design, by KPFF Consulting Engineers & ERA Structural Engineering, is organic and created a few challenges—namely, shrinkage of the SRT.

The wood materials, from certified forests, reduce embodied carbon, support circular economy principles, and promote resilient forest practices by helping to slow the propagation of infestations. “While many projects begin with a clear understanding of what a cost-effective, constructable solution will look like, this project’s unique architectural vision called on us to develop a solution from scratch,” according to the project submission. “We achieved this through a highly iterative design process that included the entire design and construction teams. We studied column bay spacing to optimize truss layout, we studied more than a dozen truss configurations and geometries, and we iterated on connection details to develop the most cost-effective solutions.” Overall, this project proved to be an architectural, cost-effective, collaborative feat.

Finalist:

Warner Robins, GA | PES Structural Engineers, Inc.

Approximately 100 miles south of Atlanta, Ga., the new North Houston Sports Complex in Warner Robins is home to the city’s recreation department. It fills a gap in recreational facilities for the 10th largest municipality in the Atlanta metro region. The 77,000-square-foot Claude Lewis Recreation Center features an exposed structural steel frame, used to create large, open spaces. The design included long-span special joists to clear span the recreation courts, intentional truss design to maximize openness for the translucent Kalwall panel cladding, and a carefully coordinated lateral system that balances the desired architecture with construction cost.

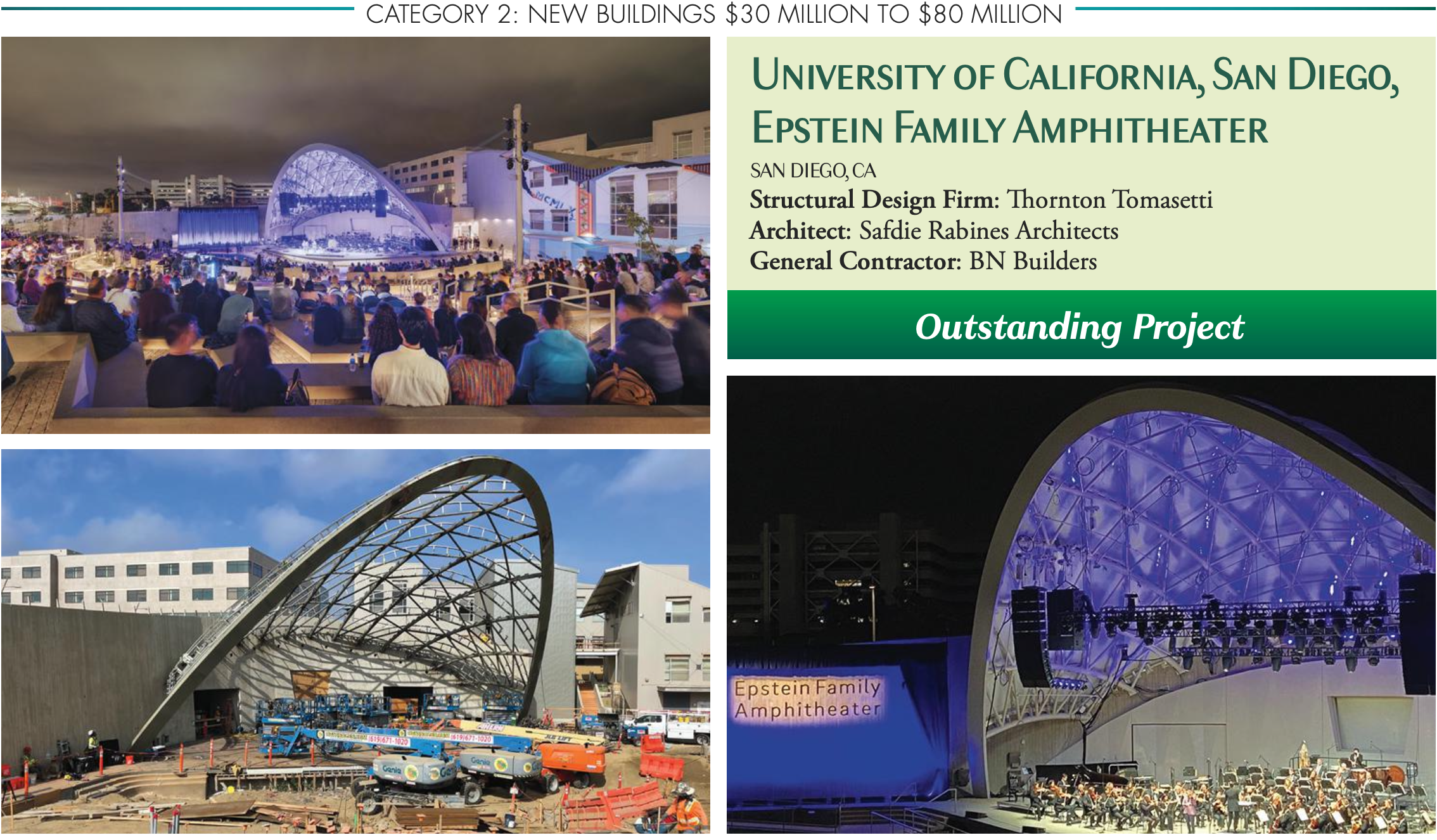

Warm and Accommodating Welcome to Campus

As the first stage of creating a “front door” to the UC San Diego campus, the Epstein Family Amphitheater was designed to fit within the landscape and offer the backdrop for events large and small—from as small as 50 to as many as nearly 2,500 people. Using an in-house software system, the design by Thornton Tomasetti included various geometric components and materials, including a concrete back wall, 40-foot tall ethylene tetrafluoroethylene (ETFE)-clad diagrid steel shell, and rounded roof slab with a vegetative roof.

The amphitheater includes a 3,000-square-foot subterranean concrete restroom facility, 400-square-foot ticketing and vending building, and the ability to support complex rigging for local theater to larger traveling performances. It features two bowl sections and a sloping lawn—all of which contributes to a design that is meant to be versatile and flexible for various types of daily and special events. From informal study sessions to exhibits and performances, this theater was designed to accommodate myriad experiences.

Finalists:

Costa Mesa, CA | John A. Martin & Associates, Inc.

OCMA’s structure enables a uniquely complex architecture while meeting critical safety and cost thresholds. Creative engineering and a collaborative process facilitated highly visible elements, such as large, column-free spaces, that support heavy plaza loads, non-orthogonal architectural elements that cantilever in places more than 30 feet off the primary structure, and a cantilever-trussed classroom wing that frames a public space. Less visible but no less important are the structure’s flexibility to withstand California’s significant seismic forces, a high bearing strength that sustainably and economically accommodates reduced column sections for thinner profiles and less material usage.

West Hollywood, CA | LPA Design Studios

The West Hollywood Aquatics and Recreation Center is made of three separate structures, each with its own set of unique structural engineering challenges. Two rooftop pools are supported by a two-way trussed space frame above 100-feet wide by 160-feet long column-free multi-court gym. Adding to the design challenge, the structure also cantilevers 30 feet over a public roadway, providing connectivity to the new Community Center, which is itself supported by an existing parking structure below. Finally, a two-level 70-foot long grand stair structure relies on a horizontally cantilevered steel truss to link the new buildings to West Hollywood Park.

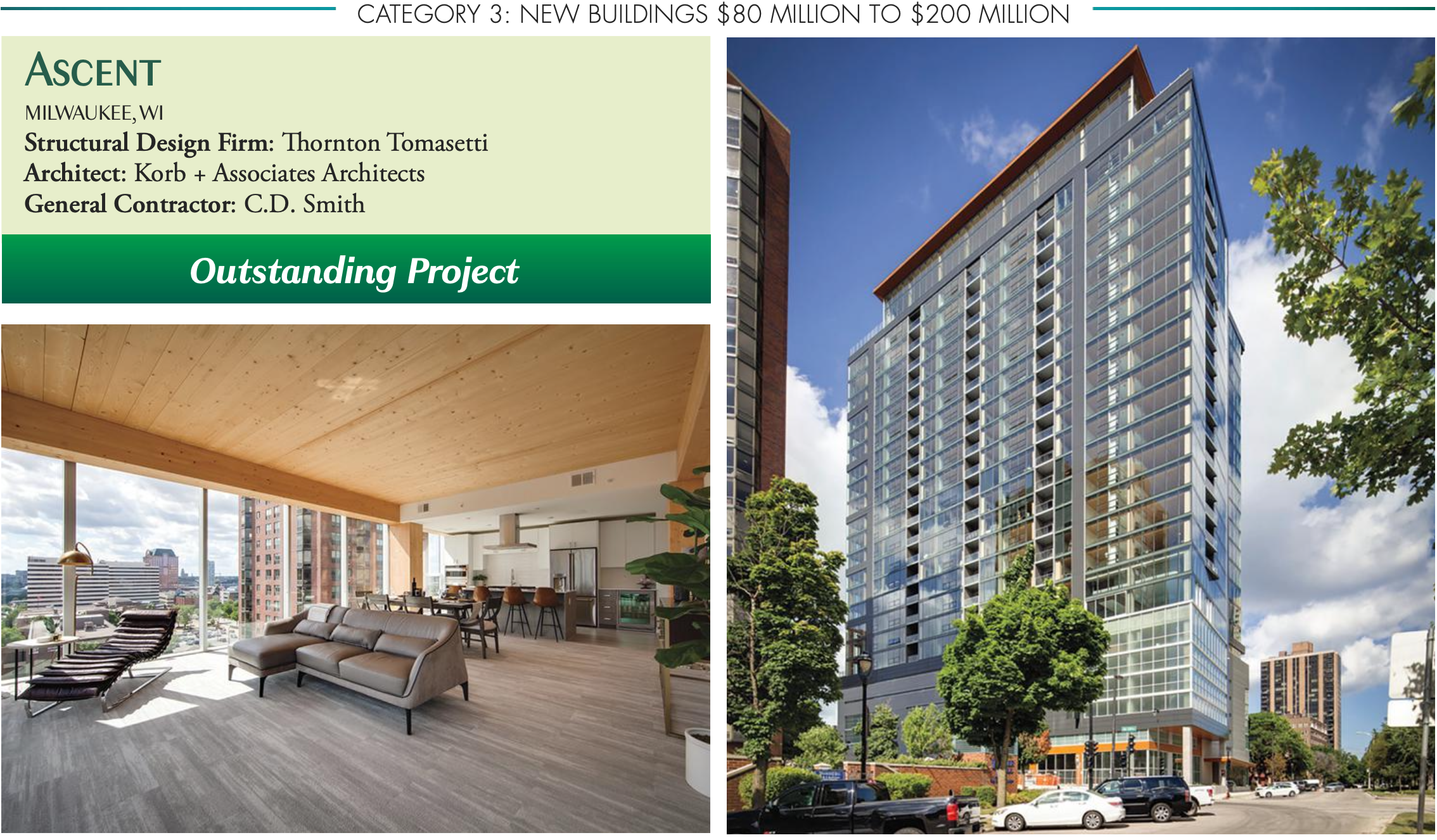

Timber! World Record-Breaking Glulam Building

The 25-story, 493,000-square-foot Ascent building is the tallest timber building in the world—and it’s helping to expand this market in the United States. The building is mixed-use, hosting 259 apartments, a 6th-floor pool, and top-floor amenities room. The first six stories, made of concrete, create a base for the 19 stories of European-sourced glulam timber. And, in total, it has optimized both financial and aesthetic considerations.

“At 284 feet tall, such a building would have been unthinkable just a few decades ago. Thanks to groundbreaking research and dedication, mass timber construction has begun to gain traction, and Ascent is the embodiment of that reality,” according to the submission. New test data, a state-of-the-art cross-laminated timber (CLT) diaphragm design, prefabrication of structural components, and timber material reduction all contributed to achieving this world record-breaking feat.

Finalists:

Toronto, Ontario, Canada | Fast + Epp

The 10-story Limberlost Place is located on George Brown College’s Toronto waterfront campus and holds the distinction of being Ontario’s first tall timber institutional building. It showcases a harmonious blend of sustainable design, structural innovation, and an advanced prefabricated envelope system. Fast + Epp developed a groundbreaking large span beamless CLT timber-concrete composite “slab band” system, accompanied by perpendicular CLT infill panels, supported on glulam columns. The unique “slab-banded” system enables architectural flexibility and unobstructed mechanical distribution. Limberlost Place has become a beacon for the mass timber movement.

Los Angeles, CA | Arup

(W)rapper, located near the Newport-Inglewood fault in Los Angeles, is a 17-story office building in Los Angeles that features a striking steel exoskeleton made of 5,000 feet of curvilinear, built-up plate boxes. In collaboration with EOMArchitects, Arup structural and civil engineers leveraged digital tools to design a base isolated, unclassified framing system in a highly seismic region resulting in one of the safest and most resilient office buildings in the world. At 180,500 square feet and 17 stories tall, this office building is the first of its kind in the city, adding aesthetic appeal and a column-free interior.

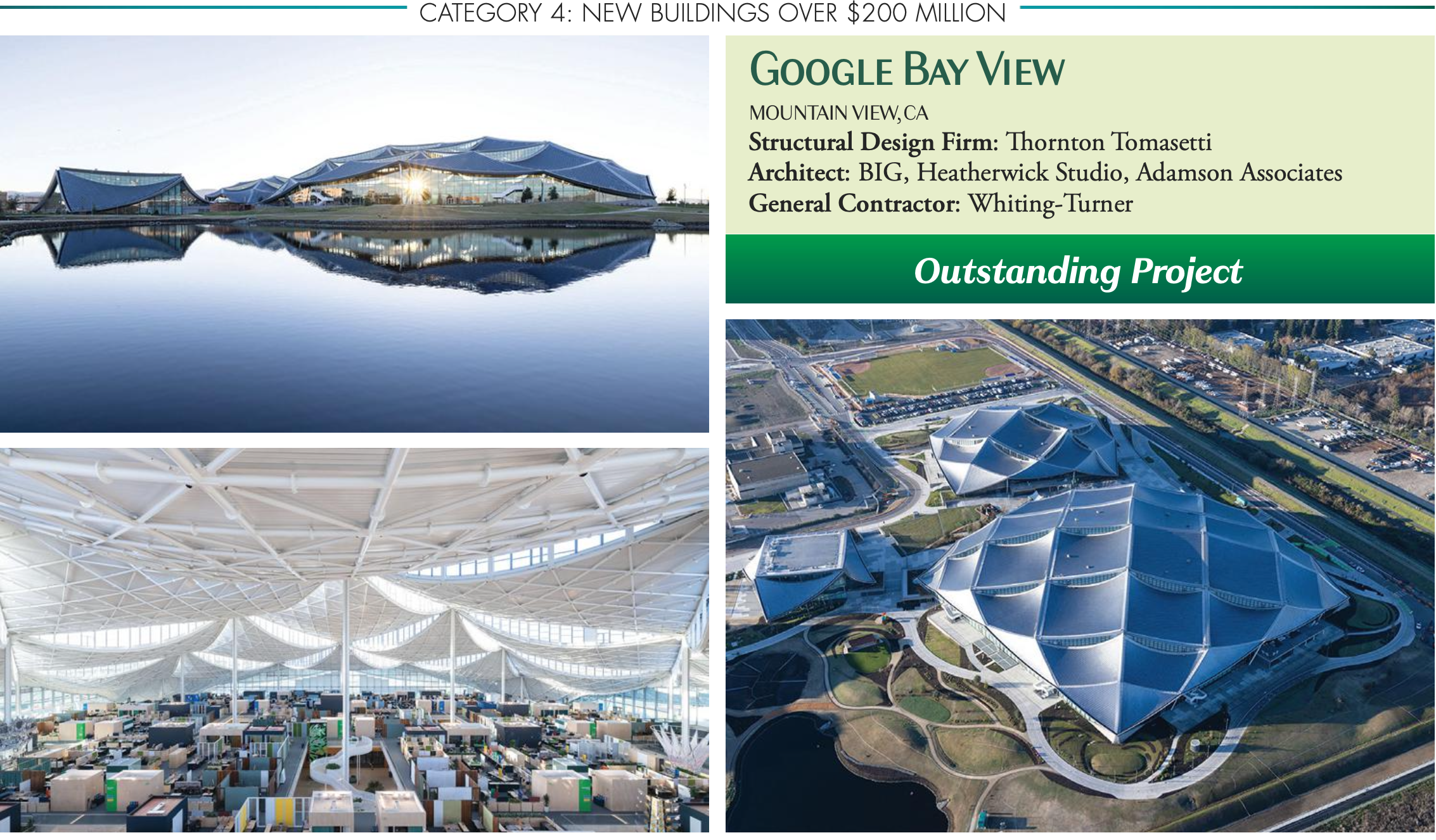

Human-Centric, Sustainable Solution Fast-Tracked for Google

Strategy and sequencing kept this fast-tracked new corporate campus for Google on schedule. The campus, called Google Bay View, is made of three separate buildings, each with roofs made of canopies that look similar to inverted shells. They’re beautiful—and they were challenging. The 400,000- to 600,000-square-foot buildings cover only two floors to help keep the buildings on the same plane.

To create the “sweeping” canopies, 160 feet above grade at the peak, the team used compressive structural typologies with tensile net structures. They achieved longer spans, 500 by 500 feet at the widest part. The results? An eggshell-thick sustainable solution that used fewer materials and offered less weight than comparable structures. Those qualities also required planning for the roof and facade. The team spent two years designing and planning to ensure the sequencing would meet this fast-tracked schedule and meet seismic standards.

“For decades, Google has been committed to providing the healthiest human-centric environments possible,” according to the submission. “Google Bay View has the largest geothermal installation in North America and a water-positive campus that shows what’s possible. These are some of the largest buildings in the world to pursue LEED Platinum v4 certification and Living Building Challenge certification.”

Finalists:

Long Beach, CA | Nabih Youssef Assoc. and Skidmore, Ownings & Merrill

The Long Beach Civic Center is a state-of-the-art facility that provides the City and Port of Long Beach, Calif., with performance-based infrastructure commensurate with its size and status as a world-class shipping and logistics hub. The center consists of an eleven-story City Hall tower, an eleven-story Port Headquarters tower, and a single-story elliptical-shaped City Hall Council Chambers constructed over a two-story subterranean parking garage. The City Hall and Port Headquarters towers are LEED Gold. The center is a pioneer in the use of resilience-based earthquake design and meets the Resilience-based Earthquake Design Initiative (REDiTM) Gold performance objective.

New York, NY | Severud Associates Consulting Engineers, PC

NYU’s John A. Paulson Center combines performing arts spaces, housing, and athletic facilities within one building. The five-story, steel-framed podium features a 350-seat proscenium theater and other venues acoustically isolated from noise and vibration. Steel trusses span over two below-grade levels and provide space for basketball courts and a swimming pool. The cellars were designed as a waterproofed “bathtub” and are supported by drilled caissons. An 18-story faculty housing tower and 13-story dormitory block are framed with steel and the GIRDER-SLAB system, which reduced erection time, dead load, and structural depth. The building is expected to achieve LEED Gold certification.

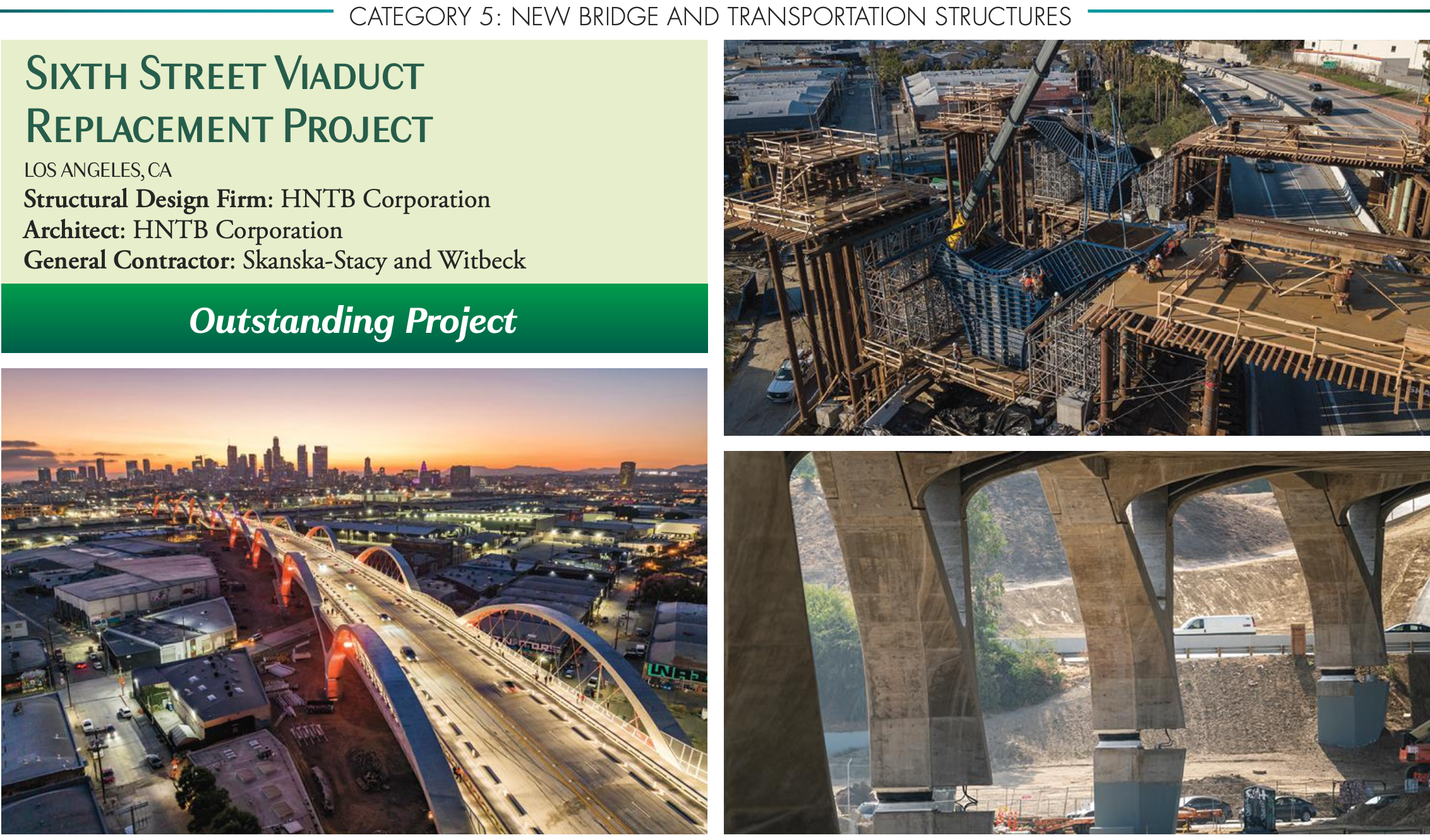

LED Lights, Camera, Action! New Viaduct Showcases Several Firsts

The new Sixth Street Viaduct opened in July 2022 and features 10 pairs of unbraced, canted arch ribs between 30 and 60 feet high in homage to the original steel double arched viaduct. The 3,060-foot-long structure crosses 18 active railroad tracks, U.S. Highway 101, and the Los Angeles River. It features programmable LED lights, five sets of stairways at the intersection of the double archways, pedestrian/bicycle ramps, and a 9-degree outward cant to offer views of downtown LA or the San Gabriel Mountains.

Behind the scenes, the team used a new seismic isolation design methodology setting a worldwide precedent using 32 isolators placed mid-height on the 18 Y-bents. According to the submission, this is the first time this method has been used in the United States and it is the longest use on a concrete network tied arch bridge in the world.

This structure showcases several other firsts, too, such as being the first California Bridge to use Grade 80 concrete reinforcement and the first U.S. bridge to use DYWIDAG multistrand post-tensioned couplers.

Finalists:

Toronto, Ontario, Canada | schlaich bergermann partner with Entuitive

This family of three bridge types (each paired for six total) are key infrastructure components of Toronto’s waterfront revitalization. The aesthetically unified bridges provide the new Port Lands neighborhood with light-rail, vehicular, cycle, and pedestrian connections, creating a critical link. Designed as hybrid shell-arch bridge structures, they are essentially curved tied arches with a planar deck connected by hangers. Innovative fabrication techniques combined with state-of-the-art engineering allowed for maximized material efficiency and reduction of costs. With four of the six now in place, the bridges have become emblematic of Toronto’s evolution, with unique and compelling structural forms.

Banff, Alberta, Canada | StructureCraft

The glacial Bow River traces its way through Canada’s Rocky Mountains and the town of Banff in one of the world’s first national parks. Spanning the Bow, in the heart of the community, is the new Nancy Pauw footbridge, fulfilling a 108-year-long dream. Responding to the wish for natural materials, StructureCraft designed and built an unusually slender 80-meter clear span out of sustainable timber, a shallow high-thrust arch that appears effortless in this beautiful setting. Its rise to span is 1:20, its span to depth ratio is more than 65, and the two bridge sections were erected in a day.

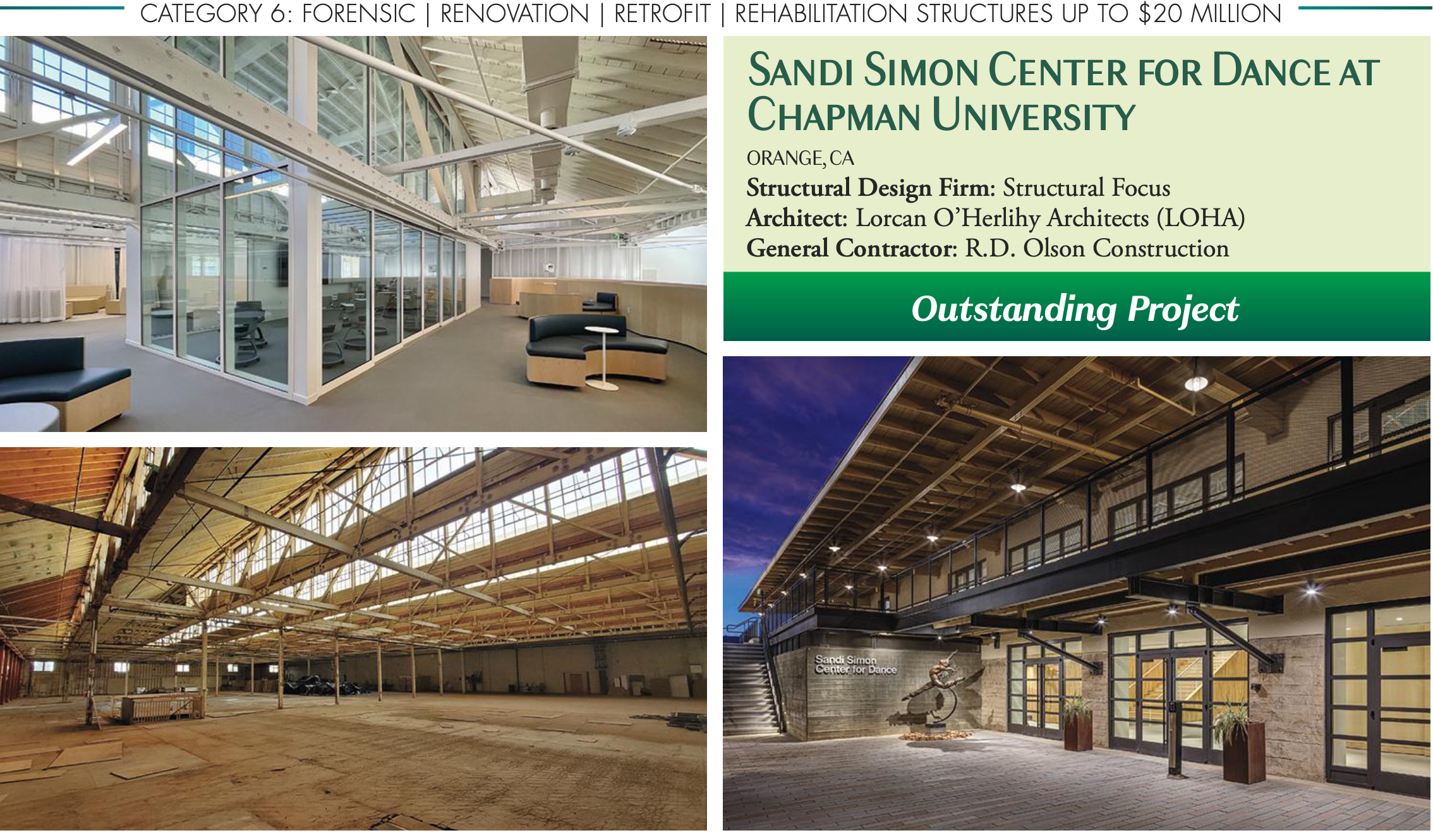

Second Chance at Showtime for Historic Building

Now home to Chapman University’s Sandi Simon Center for Dance, the 1920s industrial building originally housed a citrus packing house. To get it ready for showtime, it required historic preservation and expansions, including seismic strengthening of perimeter walls, restoration of the original sawtooth roof and clerestory windows, and aesthetic upgrades. An unconventional solution of strengthening of hollow-clay tile block wall included helical anchors, which required in situ tensile capacity testing. The roof required strengthening, too: seismic and gravity, the latter due to new acoustic ceilings and mechanical, electrical, and plumbing (MEP) distribution systems.

Despite having the same footprint as the original structure, the center now also includes a two-story mezzanine, creating light using floor opening curvatures. The original wood flooring was repurposed as wall finish. One unexpected reuse of the original structure was the canopy sag. According to the submission, “The canopy was re-supported with new steel strongbacks tied to the new steel tension-rod diaphragm and the second-floor framing. The restoration intentionally maintained the canopy sag, resulting from years of deferred maintenance, as a sign of the building’s various lifetime stages.” The center’s overall result is a balance of historic features and modern upgrades.

Finalist:

Downers Grove North High School Learning Commons Roof

Downers Grove, IL | Wight & Company

A previously unused courtyard at the Downers Grove High School in Downers Grove, Illinois, became a center for collaboration with the introduction of a new roof enclosure. Eight custom-framed king post trusses form an X shape and are framed by a steel perimeter, filling the 65-foot wide area and creating the look of a floating roof. Tubular steel purlins top the trusses to form a support for skylights and acoustical steel roof decking. Reinforcement of existing columns and the use of the courtyard as opposed to a new structure create a sustainable angle to this geometric project.

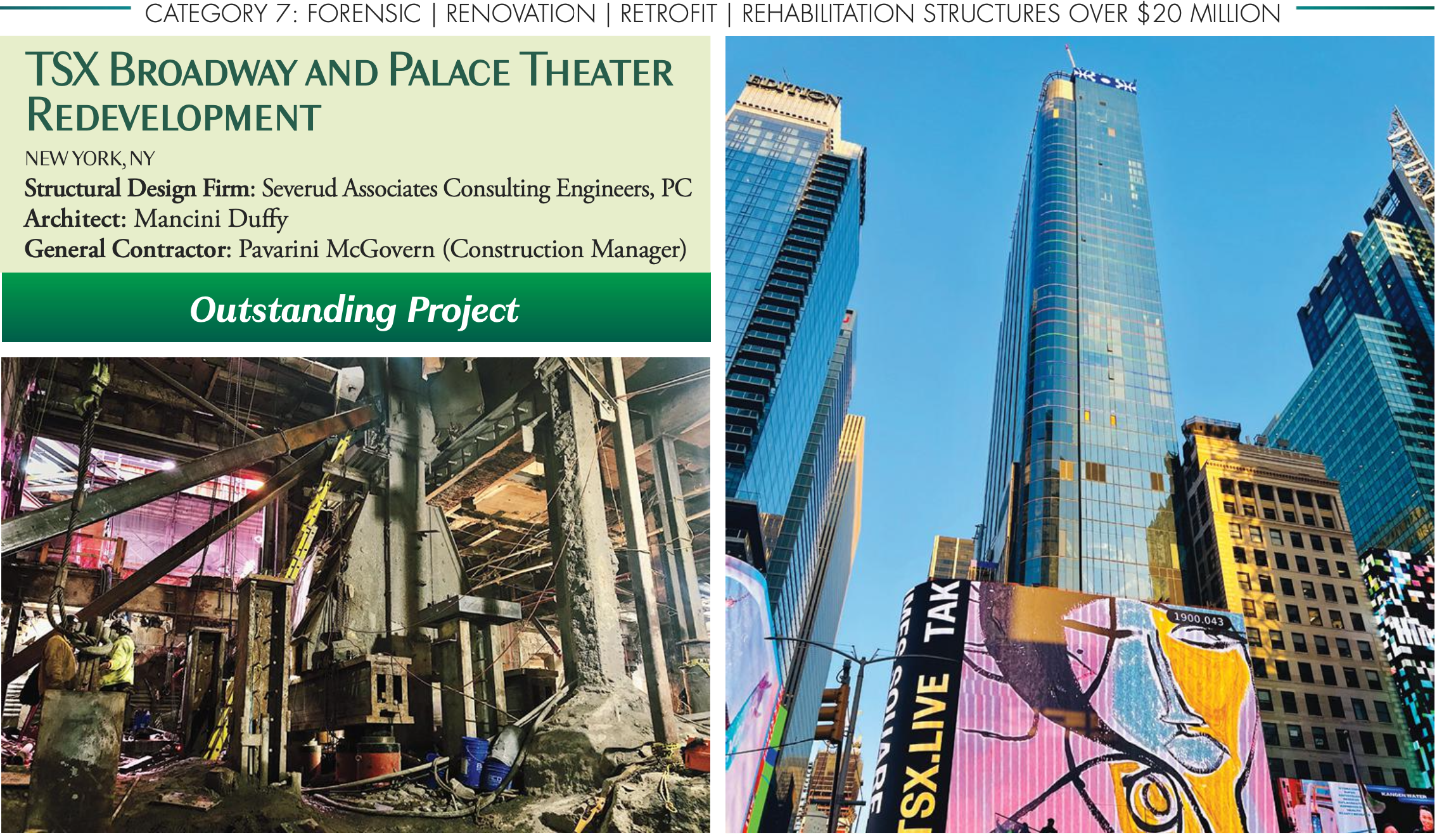

To New Heights: Historic Theater Raised 31 Feet in Times Square

Befitting the Times Square location, the TSX Broadway and Palace Theater Redevelopment included both historic components and modern advancements. That meant lifting up the 100+-year-old 8-story steel framed theater (with the 36-story concrete hotel tower that was built on top in the 1990s) 31 feet into the air to make room for storefronts below. According to the submission, “TSX Broadway expands the limits of how existing structures can be effectively repositioned and augmented to create revitalized buildings with improved functionality.”

The work that was done in the ’90s wouldn’t suffice for the new lift of the building, 25 million pounds per column, so the updated design included post-tensioning girders, encasing steel columns with concrete reinforced with rebar, demolishing old columns, bonding or doweling new concrete to existing slabs, and drilling caissons below the cellar into the bedrock.

“TSX Broadway makes a significant contribution to sustainability as a large-scale reuse of an existing facility,” the submission continues. “Complete demolition would have been wasteful while retaining 25 percent of the floor construction reduced the demand for new materials. All concrete sub- stituted slag for up to 40% of standard cement; reinforcement and structural steel framing contain over 90% recycled material.”

Finalists:

DENVER, CO | MARTIN/MARTIN, INC.

The Colorado Convention Center embarked on one of the largest overbuild expansion projects in the United States, adding 200,000 square feet of usable space above its existing facility. To overcome the challenges of this massive, overbuild expansion, the design-build team employed creative design and construction methods. The team collaborated closely to work within the limitations of the existing structure with minimal disruptions to the convention center’s operations. The expansion’s unique features include cantilevered floor spaces, innovative use of existing columns, and multi-function floor trusses engineered to support a 500-ton crawler crane during construction.

San Diego, CA | LPA Design Studios

University of California, San Diego’s York Hall, built in 1966, is a 122,000-square-foot historic mid-century building. Immediately recognizable perched atop its 300-foot long fluted column arcade, the lift-slab buildings are ringed with more than 800 quarter-ton, precast concrete fins. A seismic retrofit meeting the University of California’s seismic performance standard preserved the historically significant architecture and kept the building fully operational during construction. The seismic retrofit included the complete replacement of multiple historic fluted concrete columns, new shear walls, and strengthening of three-quarters of the precast concrete fins.

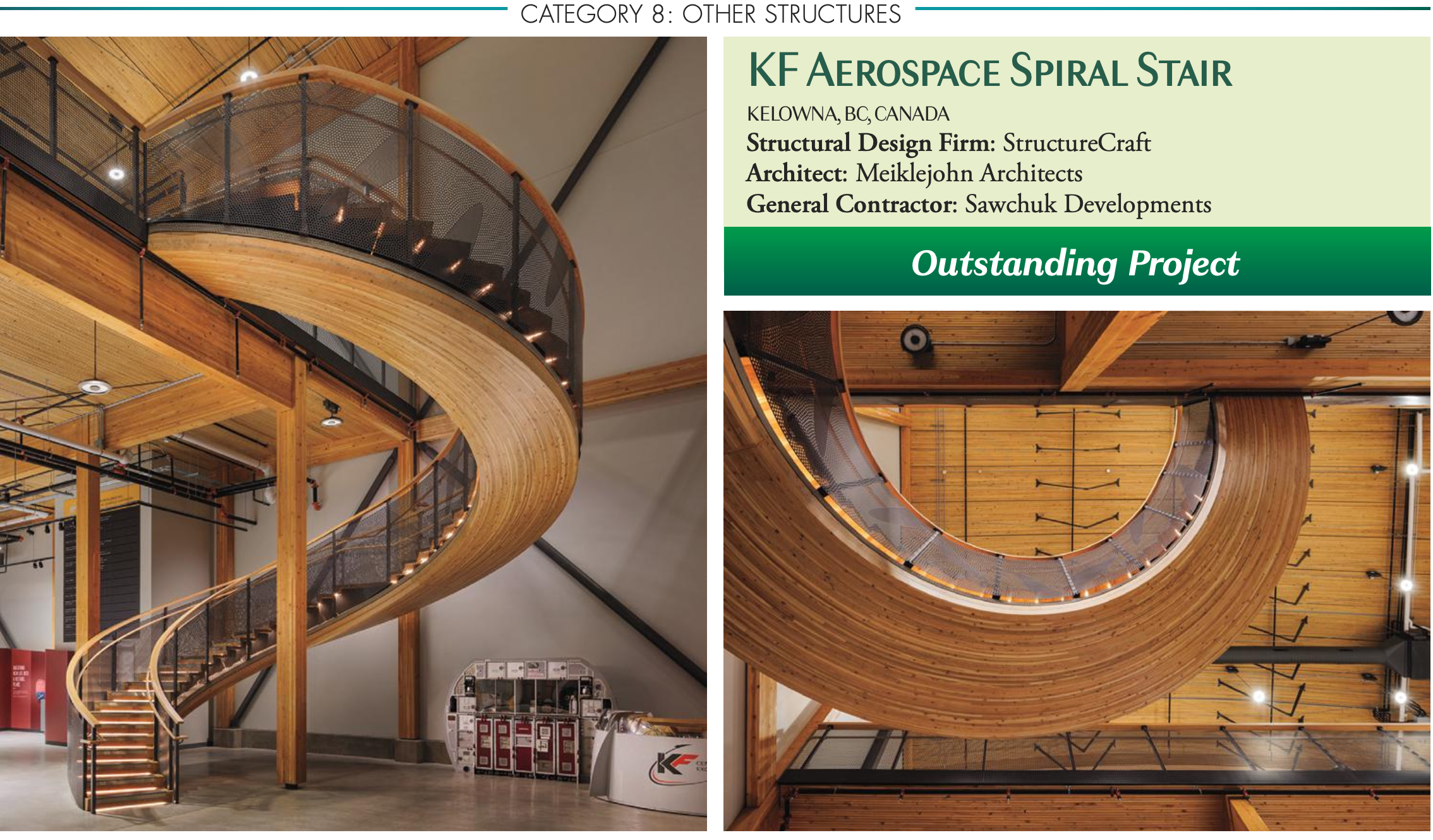

Free-Standing Stairway to Space: CLT Used to Ascend

Befitting the aerospace client, StructureCraft designed a free-standing cross laminated timber (CLT) 70-foot spiral staircase connecting the first and second floors. The solution needed to be able “to both bend and warp and create forces in combination of short- and weak-axis bending as well as torsion,” according to the submission, and without any cut-offs. This may be the first time CLT has been manufactured in this way. Another unique aspect was the use of thin boards glued to the edge on the top and bottom layers and a cross layer of boards on the flat side.

The team used models to consider solutions to challenges, such as predicting spring back and understanding the flow of the timber/concrete composite sections. Aesthetics were also a concern, especially at the base of the stairs where the connection was. The team came up with a solution to create a sculptural concrete bullnose, located under the stairs. On the second story, the team tied the concrete topping into the floor slab.

Installation proved challenging as well, since the second floor wouldn’t allow for a crane to lift the lower half in place. Instead, the team used a rigging system, hooked up to the existing beam structure, and lifted manually with adjustable chain hoists. Bottom, middle, and top connections lined up perfectly on site; the concrete was poured; and the unsupported spiral stairway was complete.

Finalists:

New York, NY | CRAFT | Engineering Studio

CRAFT | Engineering Studio developed a structurally superior curved stair design alternative without requiring specialty fabrication equipment. They used a planar mesh of triangular flat plates to create a curved surface, maximizing the staircase’s cross-sectional properties. Each plate was laser cut from sheet steel and assembled in a single shop, minimizing errors. Customized stair sections were fabricated as welded assembly modules, providing flexibility in module sizes based on delivery and site access. The innovative approach improved efficiency and accuracy.

Buffalo, NY | Thornton Tomasetti

Common Sky is a work of art and functional canopy enclosing the Albright-Knox Gallery’s Town Square. Angled facets of glass and mirrors transform the square with kaleidoscopic light and shadow. The canopy reaches down to the ground at a single point, maintaining the space’s asymmetry. The canopy is composed of steel hollow sections, arranged in two layers. They are supported at the perimeter on spherical slide bearings installed atop existing building columns and within the courtyard by a new trunk column and footing. Due to the arched geometry, the roof is of variable height with a maximum overall elevation of 23 feet.