Pedestrian Bridge

Pedestrian bridges are a vital part of modern hospital complexes, providing weather-protected connections for patient transfer and staff connectivity. They are also a great opportunity for merging engineering creativity with architectural expression. Emory University Hospital Midtown is a large hospital in the SoNo district of Atlanta, Georgia, with an over 100-year history.

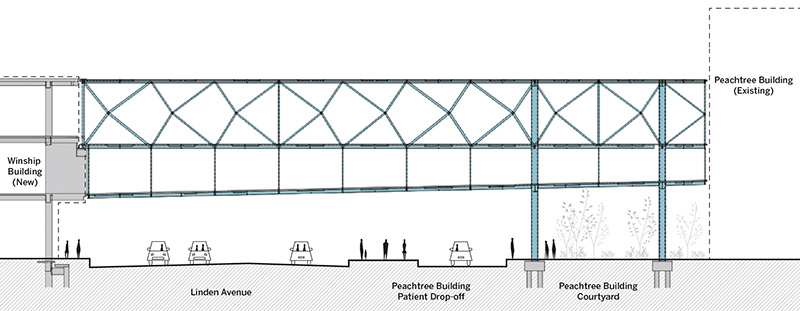

In the spring of 2023, a new building for the Winship Cancer Institute, designed by Skidmore, Owings, & Merrill (SOM) and constructed by Batson-Cook Construction (BCC), was completed across Linden Avenue from the main hospital campus. The hospital planned a double-level bridge to link the new building to the rest of the complex. The lower level would connect public spaces on both sides, and the design team wanted it to be as open and transparent as possible. The upper level would provide patient access and was required to have fritted glass to offer the necessary patient privacy. The bridge would also carry mechanical, electrical, and plumbing services across the street to the new hospital.

Design

When designing an efficient truss, it is common to adhere to typical span-to-depth ratios for a single level truss. Thus the sides of the top level of the bridge are full-depth trusses, and the lower level hangs from HSS hangers at each truss point. Besides these efficiency and constructability considerations, this choice also reflected the functional differences between the two levels. The top private level is more enclosed, while the lower public level is as transparent as possible.

One challenge for the designers was that the elevations of the corresponding levels between the old and new buildings do not align. The lower level has to reconcile an elevation change of 4 feet 1 inch and the upper level a change of 1 foot 4 inches. It was decided to connect the two springing points with straight and slightly inclined walking surfaces to meet the maximum allowable slope. The team then investigated several options for forming the geometry of the structural elements to accommodate these elevation constraints. The solution was to keep the top and bottom chords of the truss horizontal to simplify fabrication, but more importantly, to preserve the clarity and purity of the truss geometry.

Additionally, this configuration maintained a consistent node geometry to facilitate fabrication and provided a regular datum for the attachment of the facade modules. The slope of the walking surface was achieved using a slab-on-grade over-shaped geofoam. The bottom level framing, which hangs from the truss, was sloped to follow the walking surface. The lower level facade units thus extend down from the bottom of the structure along the bridge in order to avoid trapezoidal glass elements.

Between the existing hospital and the new building lies the busy three-lane Linden Avenue, a patient drop-off area for the current hospital’s Peachtree Building, and an exterior courtyard. While locating supports for the new pedestrian bridge adjacent to the street would provide the shortest spans for the bridge, it would have resulted in the significant rework of the drop-off area and entrance to the Peachtree Building. Rework for both of these areas was not an option for the facility to remain open during the bridge construction. As a result, the team determined that the most appropriate approach was to provide one 134-foot-long span across both the street and drop-off zone, supported by the Winship building to the north and a pair of columns in the landscaped courtyard to the south. From there, a shorter adjacent span and second support location carry the cantilevered south end of the bridge structure. The cantilevered end of the bridge eliminates two potential problems. First, it allows the bridge to interface with the Peachtree Building without imposing new loads on the existing building’s structure while simultaneously locating any new bridge foundations away from the existing footings. This approach permitted the continuous operation of the Peachtree Building with no structural enhancements required. All told the bridge covers 184 feet in length between the two buildings with minimal impact on Linden Avenue, the hospital drop-off, and the existing building.

Lateral support for the bridge structure is provided in three locations; at the connection to the new Winship Building and at each vertical support in the existing courtyard. At the Winship Building, lateral forces are transferred from the bridge into the building structure through a series of sandwiched bearing plates at each level and distributed into the reinforced concrete floor framing and diaphragms. At the two bridge supports to the south, moment-resisting frames provide the lateral strength and stiffness required for the bridge. The frames consist of 24-inch square built-up columns in combination with W24 beams. In-plane diaphragm bracing of the steel framing and composite metal deck slab distribute the lateral loads from the bridge spans into the lateral supports.

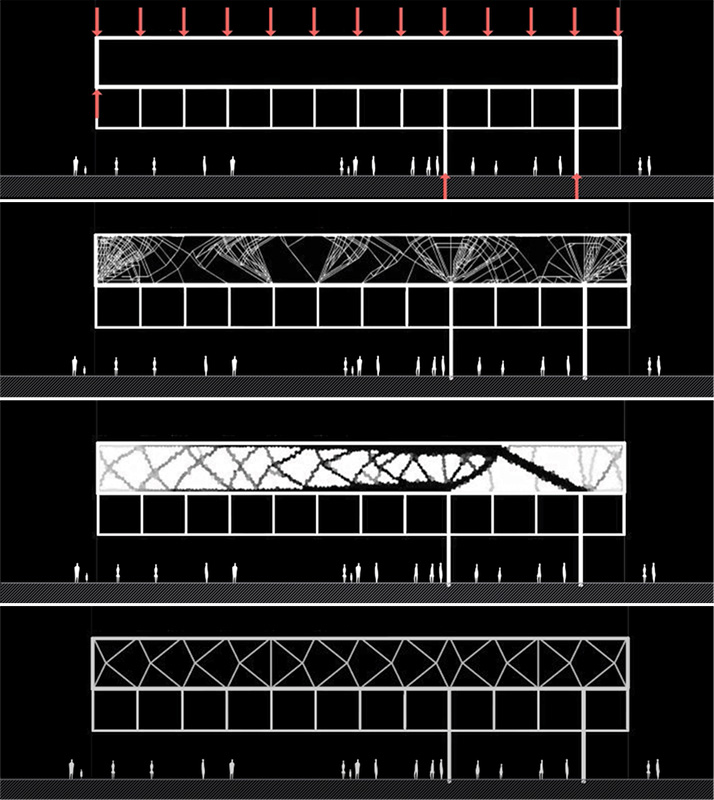

Novel Optimized Truss Geometry

The primary distinctive feature of the bridge is the upper-level truss that utilizes web members arranged in an innovative geometry that increases the structure’s efficiency. SOM used several academic and internally developed structural optimization tools that iteratively remove under-utilized material to arrive at the most efficient structural form. These tools help to determine the optimized typology and geometry to minimize total material usage for the given constraints. For example, one program, Polytop, starts with a design space of a solid 2D continuum of material and iteratively removes material to arrive at a solid-like approximation of the most efficient structural form. The other, Ground Structure, utilizes a design space of a densely interconnected grid of linear elements and iteratively removes members to arrive at a sketch-like approximation of the most efficient structural form. The results from these programs are then combined with an applied rationalization considering the fabrication and construction of the bridge. The resulting geometry consists of truss bays with skewed X-bracing that is symmetrically oriented about the mid-span of the bridge.

SOM has successfully designed a number of high rises with a similar geometry for vertical bracing, including the recently completed 100 Mount Street in Sydney, Australia, and 800 Fulton Market in Chicago, Illinois. However, the Emory Winship at Midtown Bridge is the first constructed example of a long-span structure using this truss geometry.

The truss diagonals were considered Architecturally Exposed Structural Steel. As such, the team made many design choices for aesthetic purposes and to facilitate construction. First, the decision was made to maintain a consistent outer dimension for all the truss diagonals within each truss bay to ensure visual continuity of elements and avoid connections with members of varying dimensions. Similarly, changes in member dimensions between bays were kept to a minimum to transition along the truss seamlessly. At the asymmetric connection of the truss diagonals, a milled steel node was used to provide a clean, easily repeatable piece for a consistent connection of the diagonals. The resulting truss consists of W12x96 top and bottom chord members, while the truss diagonals comprise HSS4x4 through HSS 8×8 elements.

Erection

The Emory Bridge spans Linden Avenue, a highly trafficked road that functions as an on-ramp to Interstate 85. As the team engineered the erection sequence, they wanted to minimize the time the road was closed to traffic. In addition, the team wanted to erect the largest sections possible to minimize the amount of work that would take place over the road. The trusses were fabricated and assembled in the shop and delivered to the site in 40-foot pieces. One lane of Linden Avenue was shut down and used as a laydown area to assemble the pieces into large truss sections on the ground and minimize the amount of overhead welding that would need to be done on the bridge while suspended. Next, the top and bottom chords of the trusses were welded together, and then the intermediate beams were installed to create two large box trusses that could be erected quickly and safely over the road.

Once the box truss sections were complete, a total road closure for Linden Avenue was instituted, and two mobile cranes were used to lift the two box trusses into place. These sections were bolted together while suspended in the air, and the cranes remained hooked to the trusses until all back welds were complete. Next, a team of four ironworkers worked through the night to complete 12 large complete-penetration welds and the bridge tie-in. After 23 hours of continuous work, the welds were inspected, and the cranes released the trusses. Over the next several days, the bridge’s lower-level was hung from the trusses, allowing Linden Avenue to be reopened. The deflection of the bridge was measured and compared with predicted values at the completion of the trusses, after the erection of the lower level steel and after the placement of each of the three slabs.

Conclusions

The new pedestrian bridge connecting the Winship Cancer Institute to the rest of the existing Emory Midtown Campus utilizes a steel truss with a novel optimized geometry providing an efficient and elegant span over Linden Avenue.■