Part 3: Special Inspections (Chapter 17)

This five-part series (Part 1, STRUCTURE, November 2021, Part 2, December 2021) includes discussion of significant structural changes to the 2021 International Building Code (IBC) by the International Code Council (ICC). This installment includes an overview of changes to Chapter 17 on special inspections and testing. Only a portion of the total number of code changes to this chapter are discussed in this article. More information on the code changes discussed here can be found in the 2021 Significant Changes to the International Building Code, available from ICC (Figure 1).

IBC Chapter 17 provides various procedures and criteria for inspection, testing, and labeling of materials and assemblies. Its key purpose is to establish where additional inspections/ observations or testing must be provided and what submittals must be provided to the building official. The following modifications were approved for the 2021 IBC. Changes are shown in strikethrough/underline format with a brief description of each change’s significance.

Structural Observations

Structural observations are now required for all buildings assigned to Risk Category III or IV. Additional clarification provides clear direction for the duties of the structural observer.

1704.6 Structural observations. Where required by the provisions of Section 1704.6.1, 1704.6.2, or 1704.6.3, the owner or the owner’s authorized agent shall employ a registered design professional to perform structural observations. The structural observer shall visually observe representative locations of structural systems, details, and load paths for general conformance to the design intent as defined in the approved construction documents. Structural observation does not include or waive the responsibility for the inspections in Section 110 or the special inspections in Section 1705 or other sections of this code. [unchanged text omitted for brevity]

1704.6.1 Structural observations for structures. Structural observations shall be provided for those structures where one or more of the following conditions exist:

1. The structure is classified as Risk Category III or IV.

Change Significance: The new description in Section 1704.6 is intended to provide clear direction for the duties of the structural observer. The structural observer is expected to observe, gravity and lateral force resisting systems, connection details, and gravity and lateral load paths. The clarification is also intended to help address a widespread perception of overlap between special inspections and structural observations. Special inspections are very detailed inspections of components and materials within structural systems. Special inspections require certification and specialized training, but they do not necessarily require an understanding of how systems are designed to function as part of the overall building.

Risk Category III includes categories of buildings that represent a substantial hazard to human life in the event of failure. Given the relative risk and hazard, it is appropriate to require that a structural engineer conduct site visits to verify general conformance to the design intent for these structures.

In reading the 2021 IBC code text, it may be noted that there are no longer separate categories for wind and seismic structural observations. The requirements for observations were folded into the updated text within Section 1704.6.

Precast Concrete

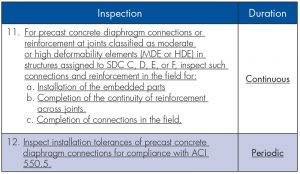

Special inspection requirements are added to Table 1705.3 for precast concrete diaphragms.

Change Significance: The American Concrete Institute’s updated standard ACI 318-19, Building Code Requirements for Structural Concrete and Commentary, has new provisions for designing precast concrete diaphragms in Section 18.12.11. The new ACI 318 Section 26.13.1.3 requires special inspection of panel placement and reinforcement in precast concrete diaphragms assigned to SDC C, D, E, or F using moderate or high-deformability connections. These diaphragms are also required to comply with the requirements of ACI 550.5-18, Code Requirements for the Design of Precast Concrete Diaphragms for Earthquake Motions and Commentary. ACI 550.5 has special inspection requirements for precast concrete diaphragm connections and reinforcement at joints classified as high deformability elements or moderate deformability elements.

A special inspector watches the installation of the embedded parts, checks the completion of the continuity of reinforcement across the joints, as well as completion of field-built connections when structures are assigned to Seismic Design Categories C, D, E, and F. ACI 318 Section 26.13.1.3 also requires that installation tolerances of precast concrete diaphragm connections be inspected periodically for compliance with ACI 550.5.

To match these new requirements, the 2021 IBC has added two requirements to Table 1705.3. Item 11 is added as a conservative synthesis of the two requirements from ACI 318 and ACI 550.5. A continuous special inspection is required onsite during the installation of precast concrete diaphragms for moderate and highly deformable joints with a focus on the reinforcement extension through the joint, verification of embedded part location, and full connection of the diaphragm elements to one another and the rest of the seismic force-resisting system. Item 12 mirrors the ACI 318 requirement to check diaphragm element and connection minimum and maximum distances against the tolerance requirements of ACI 550.5.

Mass Timber

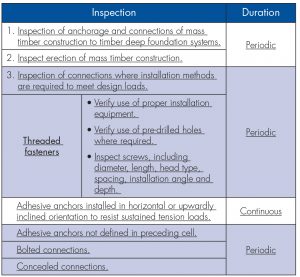

Installation and connection of mass timber elements in Types IV-A, IV-B, and IV-C construction requires special inspection.

1705.5.3 Mass timber construction. Special inspections of Mass Timber elements in Types IV-A, IV-B, and IV-C construction shall be in accordance with Table 1705.5.3.

1705.20 Sealing of mass timber Periodic special inspections of sealants or adhesives shall be conducted where sealant or adhesive required by Section 703.7 is applied to mass timber building elements as designated in the approved construction documents.

Chapter 35

ASTM D 3498 Standard Specification for Adhesives for Field-Gluing Plywood to Lumber Framing for Floor Systems

Change Significance: Special inspection provisions are added to Section 1705 for mass timber elements in Types IV-A, IV-B, and IV-C construction. The special inspections are similar to requirements for other prefabricated systems such as precast concrete and structural steel.

The specific elements requiring special inspection for construction Types IV-A, IV-B, and IV-C include:

- Connection of mass timber elements to timber deep foundation elements. These connections are critical to transferring loads from the mass timber elements to timber piles, particularly lateral loading. Connections to concrete foundations are addressed in IBC Table 1705.3 for concrete special inspections.

- Erection of mass timber elements. Similar to precast concrete, tall wood buildings utilizing prefabricated elements need verification that the correct elements are placed in the right location in accordance with the design drawings.

- Specialized connections between mass timber products that utilize threaded, bolted, or concealed connections are similar to concrete connections. The strength of many connection designs is predicated on specific screw lengths and installation angles. Bolted connections require specific diameters and, for lag screws, specific lengths. Concealed connectors, many of which are proprietary, must be installed correctly for structural performance.

- Adhesive anchorage installed in horizontal or upwardly inclined positions resisting sustained tension loads requires a continuous special inspection. This is necessary because of issues with creep in the adhesives under long-term tension loading. All other adhesive anchors need only be inspected periodically.

If, in the judgment of the building official, there are other unusual items not covered in Table 1705.5.3, the existing text in Section 1705.1.1, Special Cases, requires special inspection of these items as well. The same section also says the building official can require special inspections where a manufacturer’s installation instructions prescribe requirements not contained in the code. For example, field-glued mass timber beam or panel splices, while currently rare in North America, may become more prevalent in the future. Section 1705.1.1 would allow the building official to require special inspection for either proprietary or non-proprietary field-glued splices. Additionally, many design engineers specify the need for special inspections for unusual conditions in their structural notes in the construction documents and the statement of special inspections.

The new Section 1705.20 requires periodic special inspection of sealants or adhesives where sealant or adhesive required by IBC Section 703.7 is applied to mass timber building elements as designated in the approved construction documents. New Section 703.7 requires sealing between mass timber elements in Type IV-A, IV-B, and IV-C construction to resist the passage of air at the following locations: 1) at abutting edges and intersections of mass timber building elements required to be fire-resistance rated, and 2) at abutting intersections of mass timber building elements and building elements of other materials where both are required to be fire-resistance rated. Sealants must meet the requirements of ASTM C 920, Standard Specification for Elastomeric Joint Sealants, and adhesives must meet the requirements of ASTM D 3498.

Special inspection of mass timber sealing requirements does not apply to “joints” as defined in Section 202. These joints have their own requirements for the placement and inspection of fire-resistant joint systems in Section 715 and special inspections in Section 1705.17. Joints are defined as having an opening designed to accommodate building tolerances or allow independent movement. Panels and members that are connected do not meet the definition of a joint since they are rigidly connected and do not have an opening.

Lastly, some mass timber panels are manufactured under proprietary processes to ensure there are no voids at intersections. Where this proprietary process is incorporated and tested, there is no requirement for a sealant or adhesive.

Structural Integrity of Deep Foundations

An engineering assessment must now be done when installed deep foundation elements appear to be understrength due to quality, location, or alignment.

1705.10 Structural Integrity of Deep Foundation Elements. Whenever there is a reasonable doubt as to the structural integrity of a deep foundation element, an engineering assessment for structural integrity shall be required. The engineering assessment shall include tests for defects performed in accordance with ASTM D 4945, ASTM D 5882, ASTM D 6760, or ASTM D 7949 or other approved method.

Chapter 35

ASTM D 5882-16: Standard Test Method for Low Strain Impact Integrity Testing of Deep Foundations

ASTM D 6760-16: Standard Test Method for Integrity Testing of Concrete Deep Foundations by Ultrasonic Crosshole Testing

ASTM D 7949-14: Standard Test Methods for Thermal Integrity Profiling of Concrete Deep Foundations

Change Significance: Most foundation failures are caused by inadequate soil bearing or lateral capacity. Section 1705.10 addresses a less common failure – lack of structural integrity in a deep foundation element due to material defects. Significant defects may affect the structural strength of deep foundation elements; therefore, the defects must be detected and corrected prior to the construction above ground.

When the integrity of a deep foundation element is in doubt, for example, due to issues in alignment during installation, problematic soil conditions, or inadequacy of construction procedures, a deep foundation element should be load-tested during installation to assure that there are no material defects (Figure 2). The 2018 IBC already addressed visual special inspection of deep foundations in Sections 1705.7, 1705.8, and 1705.9. In the 2021 IBC, tests are added to the new Section 1705.10 to provide a means to assess portions of deep foundation elements that cannot be visually inspected. Testing may be done by impact, thermal imaging, or ultrasonic tests. The applicable ASTM standard is used to define the procedures for the appropriate test.

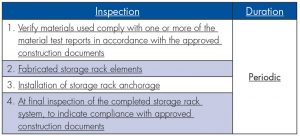

Steel Storage Racks

Steel storage rack special inspection duties have been clarified with the addition of special inspection tasks.

1705.13.7 Storage racks. Periodic special inspection is required for the anchorage of storage racks that are 8 feet (2438 mm) or greater in height in structures assigned to Seismic Design Category D, E, or F. Steel storage racks that are 8 feet in height or greater and assigned to Seismic Design Category D, E, or F shall be provided with periodic special inspection as required by Table 1705.13.7.

Change Significance: The design of the components that go into a storage rack is based on a minimum steel thickness and minimum yield strength. It is imperative that these minimum properties are included within the design for fabrication of the components and considered in storage rack installation. Storage rack systems may have complex load paths. Installation must comply with approved drawings to create the necessary load paths. Verification must be made of material minimum quality requirements during fabrication and proper anchorage during installation.

Changes clarify that periodic special inspection is required for steel storage racks, regular or cantilevered, that are eight feet or more in height in Seismic Design Category D, E, or F locations. In Chapter 2, Definitions, a definition for cantilevered steel storage racks is added for clarity.

Conclusion

Structural engineers should be aware of significant structural changes that have occurred in the 2021 IBC. Since structural engineers are often responsible for developing the statement of special inspection, awareness of these changes is essential.■