The Story of the New Multnomah County Central Courthouse

The new Multnomah County Central Courthouse is an approximately 300-foot-tall concrete building located in Portland, Oregon, completed in the summer of 2020 (Figure 1). It includes courtrooms, judicial offices, security facilities, and expanded public spaces. Built to serve as the new central courthouse for Multnomah County and to replace the historic courthouse several blocks away, the owner and design team selected enhanced, multi-objective seismic performance goals for the building. Nonlinear response history analyses revealed the unique characteristic of multi-story mechanism formation in tall concrete moment frames like those in the Multnomah County Central Courthouse. The performance-based seismic design then leveraged fluid viscous dampers to improve that performance. Finally, a partnership between the owner, design team, contractor, Oregon Department of Geology and Mineral Industries, and the U.S. Geological Survey succeeded in seismically instrumenting the building with a dense array of accelerometers.

Concrete Moment Frames

The Multnomah County Central Courthouse’s architectural layout did not provide for locations of solid lateral force-resisting system elements (e.g., shear walls or braced frames) that stack vertically at every floor. Additionally, the design team sought to balance the center of rigidity with the center of mass by providing lateral force-resisting system elements in both legs of the L-shaped plan. These constraints led the team to choose special reinforced concrete moment frames as the primary lateral force-resisting system. While special reinforced concrete moment frames can be designed prescriptively per ASCE 7-16, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, Multnomah County sought enhanced seismic performance beyond that achieved by the building’s Risk Category III code designation.

Specifically, the owner and design team selected serviceable performance (i.e., essentially elastic) for a 43-year return period earthquake, repairable performance for a 475-year return period earthquake, and a reduced probability of collapse (compared to a standard code building) for the Risk-Targeted Maximum Considered Earthquake (MCER). The 43-year and MCER hazards, and their corresponding performance objectives, are standard criteria in the Pacific Earthquake Engineering Research Center’s (PEER) Tall Buildings Initiative (TBI) Guidelines for Performance-Based Seismic Design of Tall Buildings and the Los Angeles Tall Buildings Structural Design Council’s (LATBSDC) An Alternative Procedure for Seismic Analysis and Design of Tall Buildings Located in the Los Angeles Region. The additional repairable performance objective for a 475-year return period event included limiting inelastic actions (e.g., moment frame beam plastic rotations) to Immediate Occupancy thresholds. Most importantly, it also imposed a stringent residual drift criterion based on FEMA P-58, Seismic Performance Assessment of Buildings.

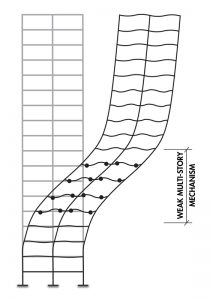

The nonlinear response history analyses in PERFORM-3D illustrated a weak story deficiency in the prescriptive design procedures for tall concrete moment frames. Strong column-weak beam requirements in ACI 318-14, Building Code Requirements for Structural Concrete, and prohibition of certain ASCE 7-16 vertical irregularities (i.e., Discontinuity in Lateral Strength – Weak and Extreme Weak Story Irregularities) are intended to control weak stories. However, they do not appear sufficient for taller concrete moment frames. Notably, even when each story below is stronger than the one immediately above and strong column-weak beam checks are satisfied, a weak multi-story mechanism can still form (Figure 2). For the Multnomah County Central Courthouse, the design team suppressed the weak multi-story mechanism through a combination of tuning the story strength profile versus height and utilizing fluid viscous dampers. Interestingly, the team discovered that commonly practiced design decisions (e.g., grouping beam reinforcing for detailing simplicity, increasing beam sizes only at certain levels to satisfy wind demands, etc.) could lead story strengths to significantly exceed earthquake demands in certain multi-story bands. Although intuitive in hindsight, the best performing design was where the story shear earthquake demand-to-capacity ratio was approximately equal at all stories, thus more uniformly distributing inelasticity.

It is also important to note that a weak multi-story mechanism is further exacerbated by ratcheting (i.e., an increase in unrecoverable drift in one direction with each cycle) due to P-Delta effects under moderate to large story drifts. The fluid viscous dampers were integral in reducing drifts and therefore preventing P-Delta ratcheting. The damping provided by the fluid viscous dampers could be visually seen in the nonlinear response history analyses where a “wave” of building deformation due to ground shaking would be gradually damped out as it moved up the structure.

Fluid Viscous Dampers

Fluid viscous dampers are seismic protective devices very similar to an automobile’s front struts. Or, if you still remember what it was like to fly on an airplane, the tiny pistons that slowly open the overhead baggage compartments. In more technical terms, fluid viscous dampers are devices that exhibit a force-velocity relationship and minimal force-displacement response. The design team chose fluid viscous dampers for the Multnomah County Central Courthouse because they dissipate earthquake input energy in a manner that minimizes the increase in force/acceleration experienced by the building. They also do so without sustaining damage. See Figure 3 for construction photos of the fluid viscous dampers.

ASCE 7-16 introduced the concept of property modification factors for designing structures with damping systems. Property modification factors represent the variation of expected properties for effects that may impact the damping devices over their design life (e.g., manufacturing variability, dynamic cycling, aging, etc.). For the fluid viscous dampers in the Multnomah County Central Courthouse, KPFF specified the property modification factors and testing by which to establish them. KPFF then conducted upper- and lower-bound nonlinear response history analyses in PERFORM-3D based on these limits. The damper supplier, ITT Enidine, confirmed the damper design against this specification, including 100% testing of all devices supplied for the project. KPFF also determined the minimum damper stroke and force capacity based on the greater of the suite maximum and amplified suite mean demand aligned with ASCE 7-16 Chapter 16 criteria, the project’s basis of design, and the peer review team.

Seismic Instrumentation

The Oregon Structural Specialty Code (OSSC), the governing building code in Oregon, requires buildings over certain height and floor area combinations to be seismically instrumented. However, these provisions require the minimal instrumentation of one accelerometer location at each of the “lowest floor level, midportion, and near the top of the building.” Additionally, with only one location per floor, torsion cannot be measured.

Instrumentation maintenance is left to the building owner with practically no city or state agency oversight. As a result, many buildings in Oregon that had instrumentation installed based on this code requirement now have unconnected, damaged, or missing accelerometers. Unfortunately, when an earthquake does occur, these buildings will not record the valuable data for which this code requirement exists.

The design team brought this reality to the attention of Multnomah County. They then helped connect the County with the Oregon Department of Geology and Mineral Industries (DOGAMI) and the U.S. Geological Survey (USGS). These groups collaborated to instrument the Multnomah County Central Courthouse with 21 accelerometers manufactured by Kinemetrics to measure orthogonal translations and torsion of approximately every third floor, plus vertical at the base. Figure 4a shows two of the installed accelerometers. For perspective, the code minimum instrumentation layout would only have required six accelerometers. DOGAMI provided funding to offset the additional costs above the code minimum system from a fund paid into by projects that take exception to the OSSC instrumentation requirement. USGS performed the installation, connected the system to their real-time National Strong Motion Network, and contracted with Multnomah County to perform future maintenance. After an earthquake, recorded data will be transmitted to USGS within minutes. In the event of loss of power during the earthquake, the building’s uninterruptible power supply system keeps the accelerometers and data collector running. Redundant local backup batteries also exist. If the belt and suspenders fail, the data is stored locally for in-person retrieval.

At the time of this writing, the Multnomah County Central Courthouse has not experienced a significant earthquake. However, the instrumentation was functioning during the Mw 5.8 Lone Pine earthquake in eastern California on June 24, 2020. Although the epicenter was almost 700 miles away, the Multnomah County Central Courthouse sensors recorded the event (Figure 4b). This proved to be a valuable opportunity to test the proper functioning of the instrumentation system and double-check the accelerometer installation.

Conclusion

As the first new building in Oregon to utilize fluid viscous dampers and the first performance-based design of a new tall building in the City of Portland, it should be acknowledged that the Multnomah County Central Courthouse design required more communication and technical effort than a prescriptively-designed code-minimum building. However, the advantages of this hard work by the owner, design team, contractor, and collaborators are evident in the final design, contributing to a more resilient Multnomah County for the future.■

Project Team

Owner: Multnomah County

Structural Engineer: KPFF, Portland, OR

Architects: SRG Partnership, Portland, OR, and RicciGreene Architects, New York, NY

Geotechnical Engineer: GeoDesign Inc., Wilsonville, OR

Contractor: Hoffman Construction, Portland, OR

Fluid Viscous Damper Supplier: ITT Enidine, Orchard Park, NY