The dramatic new 41-story W Hotel Tower features luxury on a grand scale. Located in the heart of downtown Bellevue, Washington, within several miles of the headquarters of Microsoft, Amazon, and other global companies, it includes 245 hotel rooms and 231 upscale apartments atop a three-level podium. The podium includes boutique shops, various themed restaurants, a state-of-the-art IMAX theatre, and other recreational amenities for the public, apartment dwellers, and hotel guests. In addition, the six-level subterranean parking structure provides 2,200 spaces and connects to the adjacent Lincoln Square North via a tunnel, creating a massive parking network for over 4,000 vehicles.

The structure strategically incorporated many value-added design features, including the world’s most extensive use of a recent structural innovation – Steel Fiber Reinforced Concrete (SFRC) coupling beams.

The building utilizes cast-in-place concrete throughout. Slabs are 8-inch-thick post-tensioned flat plates, and columns are 24 × 36 inches at the base, reducing to 24 × 30 inches at upper levels. The seismic and wind force resisting system uses 36-inch-thick shear walls around the core. The foundation is a 10-foot-thick mat covering the building footprint, bearing on 12,000 psf undisturbed glacial till.

Materials

The structure effectively utilized high-strength, high-performance concrete. Columns have a compressive strength of 14,000 psi at the base, reducing to 6,000 psi at upper levels. Shear walls are 8,500 psi, slabs are 6,000 psi, and the foundation mat 5,000 psi.

All mixes used blends of cement and Supplementary Cementitious Material (SCM). The foundation mix included minimal cement and high SCM to minimize the heat of hydration. Other mixes used varying quantities of SCMs depending on short and long-term performance requirements. Slab mixes were designed to a maximum drying shrinkage of 0.030% at 28 days to minimize shortening. Concrete strengths of 10,000 psi and higher were specified at 90 days to allow added curing time.

Innovative Seismic Design

The seismic system utilized Performance-Based Design (PBD). The use of PBD allowed optimization of seismic energy, forces, and deformations. This system also resulted in shear walls with ductile behavior, a key to good seismic response.

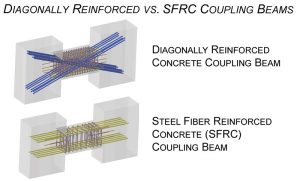

Shear walls included an innovative seismic coupling beam design. Instead of traditional diagonal bars, the beams successfully used Steel Fiber Reinforced Concrete (SFRC). In addition to reducing coupling beam rebar by approximately forty percent, SFRC created significant constructability improvements. The lack of diagonal bars eliminated the conflicts and congestion that are often created between diagonal bars and the adjacent boundary element reinforcing. Also, whereas diagonal bars are often field placed, cumbersome, and time-consuming, horizontal bars in SFRC coupling beams can be pre-tied. This accelerates rebar placement and overall shear wall construction.

The SFRC coupling beam design used methodology developed from research performed at the Universities of Michigan and Wisconsin. Fiber dosage, using a commercially available steel fiber product, was 200# per cubic yard. In the future, fiber quantities can be reduced to 170# per cubic yard based on recent tests showing that coupling beam performance at the reduced dosage is substantially unchanged.

A hidden benefit of SFRC coupling beams is that penetrations for utilities are much easier to accommodate. Since the concrete shear capacity increases from 3 to 4√fc´, depending on fiber dosage, stirrup quantities can be reduced and the spacing widened. For example, at the W Hotel, stirrup spacing was 5 inches on-center, which allowed 4-inch-diameter penetrations for plumbing, conduit, and fire protection lines. Penetrations larger than 2 inches through traditional diagonally reinforced coupling beams are seldom possible due to heavy rebar congestion.

This was only the third use of SFRC for seismic coupling beams to date, all by the same structural engineering team, and the most extensive use anywhere in North America. As with other recent projects where they have been used, SFRC seismic coupling beams were well received by the contractor, who credited them with reduced cost and accelerated construction.

High-Strength Columns

Columns utilized 14,000 psi compressive strength concrete at the base, transitioning to 6,000 psi at the top of the building. This allowed column sizes to be maintained constant throughout the building height, which accelerated construction, reduced cost, and eliminated the need to modify room layouts for varying column sizes. The high-strength concrete in lower levels was specified with ½-inch maximum aggregate and a superplasticizer to facilitate concrete placement through the heavy reinforcing cages.

Elimination of Slab Puddling

A significant challenge in high-rise concrete construction is the transfer of high-strength concrete column loads through slabs, often of much lower strength. Traditionally, the high-strength column concrete is “puddled” into the slabs around the columns immediately in advance of the slab pours. Then, as the slab is poured, slab concrete is intermixed with the column concrete that has been puddled in advance. Although effective when properly executed, this is cumbersome and often results in unintended slab cold joints between the two mixes.

A unique detail was used to eliminate slab puddling. It involved blocking out column cores with a metal screen prior to slab concrete placement, then pouring the columns above through the blocked-out slab areas. This created full column continuity, eliminating the need for puddling.

High-Strength Rebar

A706 Grade 80 rebar was used in the foundations and all shear walls. This resulted in significant cost savings since the ten percent price premium for Grade 80 vs. Grade 60 was more than offset by the twenty to twenty-five percent reduction in foundation and shear wall rebar tonnage. Grade 80 was also used for all column ties to satisfy the demanding seismic confinement reinforcing requirements for ultra-high-strength concrete. The synergistic combination of Grade 80 and A615 Grade 60, which was used elsewhere, resulted in construction and cost efficiencies throughout the project.

Long-Span Garage Framing

Parking beneath high-rise towers is typically framed with short-span systems that match or approximate the framing above. For the W Hotel Tower, parking was framed with a 30- x 50-foot system to allow the use of an angled parking layout, free of columns at the rear bumpers of stalls. An efficient combination of transfer beams and slant columns created the transfer from the parking column grid below to the tower grid above. In addition to the parking improvements, the placement of shotcrete basement walls followed behind the subterranean slab construction, which allowed the superstructure to advance at greater speed.

Performance-Based Design

Since the selected lateral force resisting system of Special Reinforced Concrete Shear Walls for the W Hotel was limited to a maximum structural height of 240 feet per ASCE/SEI 7-10, Minimum Design Loads for Buildings and Other Structures, a peer-reviewed Performance-Based Design (PBD) approach was necessary. PBD is a methodology for creating acceptable alternates to prescriptive building code requirements, contingent upon demonstrating that the proposed design meets code-intended seismic performance. This was accomplished by generating a mathematical structural analysis model used to perform non-linear analyses while considering the stiffness, ductility, and strength of critical structural elements.

The project’s geotechnical engineer developed seven pairs of site-specific ground motions by matching the source, magnitude, frequency, and duration of the risk-targeted maximum considered earthquake (MCER) spectra, which corresponds to an earthquake with an approximate 2,000-year return period for the project location. Earthquakes from Chile (2010), Tohoku, Japan (2011), and Olympia, Washington (1949) were among the base ground motions used. Typically, a building in the greater Seattle area using a code-prescribed seismic design approach would consider a design earthquake (DE) with roughly a 475-year return period. The project’s performance goals were to evaluate collapse prevention at the larger MCER ground motion, life safety at DE level forces, and to remain essentially elastic during a service level earthquake (SLE) event, with a 43-year return period.

The W Hotel Tower is an excellent example of how contemporary architecture and state-of-the-art engineering can be harmoniously combined into exceptional urban buildings. The structural features helped achieve the project’s goals of delivering a quality project on time, on budget, and to the satisfaction of all stakeholders.■

Project Team

Owner/Developer: Kemper Development Company

Structural Engineer: Cary Kopczynski & Company

Architect: HKS Architects / Sclater Architects

Contractor: GLY Construction

Geotechnical Engineer: Hart Crowser

Peer Review: Maffei Structural Engineering