Infrastructure operators are responsible for ensuring the safety and operability of large structures such as bridges, towers, tunnels, and railways. The maintenance process typically requires costly schedule-based routines that rely on periodic manual inspections, which may not always be necessary.

A more cost-effective approach involves predictive maintenance policies. Predictive maintenance is a way to remotely monitor the condition and performance of high-value structures during operations. In this way, operators can understand the structures’ current state of health and anticipate the likelihood of future problems. Predictive maintenance systems logically prioritize any needed repairs to prevent failures before they occur, thus saving considerable time, money, and resources.

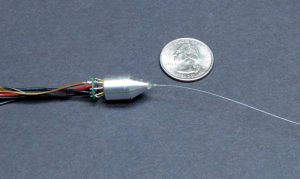

PARC developed a novel technology to read out signals from wavelength-encoded optical sensors, like FBG (Fiber Bragg Grating) sensors, with unprecedented resolution using a compact, low-cost unit that is highly customizable.

Recent advances in communications networks and advanced sensors have made predictive maintenance feasible through the Industrial Internet of Things (IIoT). New networked sensors and machine learning systems can be designed and trained to recognize structural faults and make accurate predictions about how long until components will fail.

A new IIoT System Analytics technology platform called MOXI enables engineers, operators, and maintenance professionals to monitor and proactively manage unexpected maintenance problems remotely. The IIoT suite combines embedded sensing, complex system models, and artificial intelligence technologies to predict adverse system conditions with high accuracy, negligible false alarm rates, and near-zero missed detections.

Predicting Potential Failures

The Palo Alto Research Center (PARC) is engaged on a project in Australia called Fibridge, which is sponsored by the Victorian Government’s Public Sector Innovation Fund and a partnership of Victorian Government agencies, led by VicTrack.

The Fibridge project is based on the MOXI smart monitoring system, which has the potential to enable predictive maintenance for bridges and other structures. The system uses fiber-optic (FO) sensors attached to a span to accurately measure and estimate parameters online indicative of the bridge state, including structural strain, thermal response, bending moments, shear/impact loads, and corrosion.

The system relies on low-cost, high-resolution, compact wavelength-shift detection technology, and intelligent algorithms. Teams from Victorian agencies, VicTrack and VicRoads, have provided their structural engineering expertise to enable effective real-time monitoring, performance management, better reliability, and improved safety. While Fibridge is initially targeting roadway and rail bridges, over time, it will be extendable to other structures with similar maintenance and monitoring pain points.

An initial proof-of-concept demonstration using FO sensors to monitor a VicRoads highway bridge in Melbourne, done in collaboration with AMG Systems and the University of Melbourne, has shown promise thus far. Now the technology is being scaled up towards an extended pilot trial on multiple rail, road, and transit bridges in Victoria.

Anticipated benefits of this solution include addressing risk and supporting asset management, as well as the potential for cost-savings by automating remote bridge inspection without the need for access to the structure.

FO sensors can simultaneously measure multiple parameters with high sensitivity in multiplexed configurations over very long FO cables. These parameters include strain, temperature, pressure, current, voltage, and chemical composition. And, the sensors have held up well in harsh environments.

Alerts for events of interest for bridge health can be systematized, and trends in asset deterioration can enable better planning of maintenance and renewals. Finally, the life of a bridge that is underutilized can be safely extended due to unused capacity, and maintenance scheduling can be optimized.

Promising Return-on-Investment

Over five days in October 2018, 112 FO sensors were installed throughout the structure of a VicRoads bridge in Banksia Street, Heidelberg, Victoria, Australia. The signals were bundled in groups of eight and routed to a central computing system for data acquisition and storage. For power, the system tapped into a pre-existing 240V line for the nearby vehicle messaging system sign. A router was included to allow remote user access to the system. The costs and value proposition of Fibridge over conventionally scheduled inspections were estimated for a preliminary business case assessment.

The critical pieces of technology affecting sensor costs are the FO sensors, bonding agents, optical readouts, and supporting edge devices for online processing and remote communications. Together, these sensing costs are estimated to be $2,000 for 400 sense points per bridge. This approach is at least 5X more economical than commercially available alternatives such as wireless or wired electric strain gauges.

The most significant expense for Fibridge, or any other bridge monitoring sensor system, involves the one-time installation and setup cost. This step involves some sensor array/structural installation design tuning and the cost of equipment such as boom lifts, trained technicians, and traffic management. The setup cost is projected to be roughly over $30,000 per bridge, based on local labor costs in Victoria, Australia. Installation costs are quite variable and heavily depend on the asset size, access restrictions, and narrow timeframes due to live operating environments, all of which were the case on the FiBridge trial bridges. However, there is scope to optimize the cost with the design development of the sensors for quick and easy installation, and better training of installation teams.

Installation costs would also drop if the sensor system were fitted to new bridges during construction. This would also provide initial data from the early days of structural settling and initial use that could be used for baselining.

Installation of the PARC MOXI smart monitoring system on one of the VicRoads’ bridges in Victoria, Australia. Based on fiber-optic (FO) sensors, MOXI accurately estimates parameters indicative of the bridge health state.

The preliminary assessment assumes a conservative two-times extension of bridge inspection intervals. This extension will reduce costs and downtime from schedule-driven inspections, avoid liability costs associated with aging bridge structures, and defer investments from being able to safely extend the life of bridges. All taken, Fibridge is estimated to provide a greater than 50 times return-on-investment over the nominal lifetime of a bridge.

These savings do not factor in other potential benefits such as savings on follow-up engineering investigation costs, feedback for design and operations teams for improved bridge design, immediate-response ability, wider area congestion management due to events such as bridges struck by vehicles, and longer-term planning value from having reliable online monitoring into asset usage and performance.

Safety is also an area that directly benefits from real-time monitoring of bridges. Recent examples of bridge collapses are reminders that signs of rapid structural degradation due to overload, inclement weather, or hidden structural defects undetectable during visual inspections can potentially provide valuable information in bridge management.

This bridge pilot project in Australia is just one example of the practical benefits of predictive maintenance to enable self-aware, self-adaptive systems for large structures and critical assets. Infrastructure managers can now apply predictive condition-based technology solutions to proactively focus their time and resources on the most pressing maintenance problems, rather than following a rigid timetable for regularly scheduled monitoring and repair efforts.■