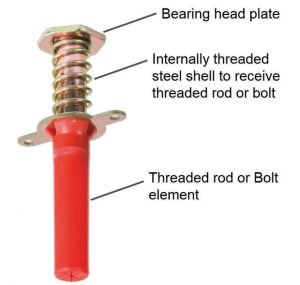

Headed cast-in specialty inserts are internally-threaded steel shell elements welded to a bearing plate that is cast into concrete members. Hilti’s KCM and Simpson’s Blue Banger Hanger anchors are some examples of headed cast-in specialty inserts (Figure 1). These anchors are used to attach structural and non-structural components. In general, the American Concrete Institute’s (ACI) Building Code Requirements for Structural Concrete (ACI 318) provides design requirements for cast-in anchors in concrete. However, the wide variety of shapes and configurations of specialty inserts make it challenging to prescribe generalized tests and design equations. Hence, they have been excluded from the scope of ACI 318.

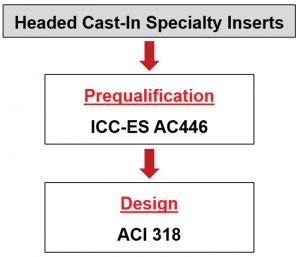

These types of inserts are ideally suited for a variety of rod hanging applications such as overhead vertical supports and seismic restraint anchors for suspended mechanical, electrical, plumbing, and fire protection systems. These inserts offer significant time savings over traditional post-installed anchors. However, design engineers who want to specify these anchors should address the question of code-compliance since these inserts are not explicitly included within the scope of ACI 318. To address this issue, the International Code Council Evaluation Service (ICC-ES) has developed an Acceptance Criteria for Headed Cast-In Specialty Inserts in Concrete (AC446) to cover the prequalification of headed cast-in-place specialty inserts in concrete components. Headed specialty inserts satisfying the AC446 test program now receive recognition via ICC-ES Evaluation Service Reports (ESR), which provides a path to assure that the insert can be designed in accordance with the ACI 318 criteria (Figure 2). These ESR reports are ESR-4145 for the Hilti KCM anchors and ESR-3707 for the Simpson Blue Banger Hanger anchors. Note that AC446 only covers headed specialty inserts. Therefore, coil anchors, hooked bolts, or other non-headed specialty insert types are not within the scope of AC446.

Code Provisions

Testing, in accordance with AC446, establishes the strength of headed cast-in specialty inserts based on the strength design provisions of ACI 318. AC446 has requirements for the geometry and head bearing area of inserts to ensure they can achieve equivalency with the bearing behavior of headed studs or headed bolts that comply with the ACI 318 provisions. These requirements are set to ensure that the specialty insert has a strength that exceeds the calculated concrete breakout strength when the 28-day compressive strength (f’c) is set at 10,000 pounds per square inch (psi), the maximum compressive strength permitted per ACI 318. Also, the area and thickness of the head shall be large enough to ensure that the bearing stress on the head does not exceed 6f’c and the bending of the head plate under maximum bearing stress is small enough to accommodate the assumption of uniform stress distribution under the head.

After verifying the geometry of the head, the insert is tested in accordance with AC446 provisions to derive tension and shear strength capacities of the cast-in insert. In summary, the AC446 test program determines the following parameters for the headed cast-in specialty insert:

- Insert material characterization (ductile or brittle)

- Insert strength in tension (Nsa,insert)

- Insert strength in seismic tension (Nsa,insert,eq)

- Insert strength in shear (Vsa,insert)

- Insert strength in seismic shear (Vsa,insert,eq)

Since the shear capacity of the insert in concrete cannot be reliably calculated, AC446 requires that shear testing be performed in low strength concrete. However, to determine the tension capacity, the testing is performed in a steel jig. AC446 eliminated all concrete testing in tension for the headed insert by setting a conservative limit on the bearing stress of the head, which requires a generous head size for the insert. In this condition, the only real concern for the insert in tension will be the insert failing prematurely either at the connection of the head to the insert, at the threads, or at the insert steel shaft. These failures can be captured by utilizing a steel jig when testing the insert.

This new qualification procedure in AC446 will give designers increased confidence that they can properly design and specify the inserts and comply with the requirements of the ACI 318. By defining the insert strength and characterization, the nominal static and seismic strength of the insert steel can be reported in AC446. The nominal strength of the threaded rod or bolt, as well as the nominal strength of the concrete, must be calculated in accordance with ACI 318 provisions but should not exceed the values of insert strengths reported in AC446.

Summary

The International Code Council Evaluation Service (ICC-ES), Acceptance Criteria for Headed Cast-In Specialty Inserts in Concrete (AC446), establishes requirements for the qualification of headed cast-in specialty inserts and provides a path to designing headed specialty inserts according to ACI 318 anchoring to concrete provisions.■