After graduating from the University of Cincinnati in 1892, Joseph Strauss (STRUCTURE, October 2012) became a draftsman for the New Jersey Steel and Iron Company at Trenton, NJ. At the end of the year, Joseph went to the Lassig Bridge and Iron Company of Chicago for two years, working as a detailer, inspector, estimator, and designer. He then spent two years as a designer for the Sanitary District of Chicago, which was in the process of building a drainage channel from Chicago to Lockport using water from Lake Michigan. The project was finished in 1899 and Strauss became a Principal Assistant Engineer in charge of the Chicago office of Modjeski & Angier.

He was charged with studying the use of bascule (from the French meaning seesaw) bridges across the Chicago River that would not need a mid-river swing pier, as the War Department declared swing bridges with a central pier were obstacles to the free movement of shipping. Modjeski had been basing his bascule designs on some of the early bascules spans by William Scherzer and John Page. The earliest bascules used cast iron ingots as counterweights. Strauss presented Modjeski a design that would use concrete as counterweights, with his own system of links to lift the bridge. Modjeski did not like the plan, so Strauss resigned and went to work for the Rall Bascule Bridge Company, serving as Chief Engineer. After a year, Strauss left Rall and opened up his own office in Chicago under the name of Strauss Bascule & Concrete Bridge Company. At this time, 1902, the City of Chicago had developed an improved plan for bascule bridges and built its first one, a trunnion bascule, at Clybourn place with the counterweight under the approach to the span.

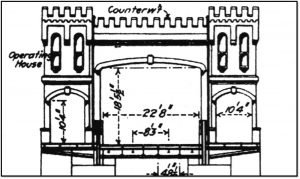

Wheeling and Lake Erie Railroad Bascule. Counterweight system where box moved down and towards the end of the span.

The first bascule span Strauss built on his own was for the Wheeling and Lake Erie Railroad (W. & L. E. or Wabash) in Cleveland, Ohio, over the Cuyahoga River. He wrote of its conception,

“High cost was, in fact, characteristic of all types of bascule bridges, due principally to the use of iron as counterweight material, and also in the underneath design to the necessity of deep pits. Elimination of these pits or frequently merely making them shallow, to reduce their cost, meant curtailment of the counterweight arm and consequent increase of counterweight to a prohibitive degree. As a result, in 1901 the limit of length and weight of bascule spans and consequently the field of usefulness, though greater than in 1893, when the Metropolitan Elevated Scherzer Bridge was built, was still greatly restricted.

In that year the writer, who had been associated with the work on practically all types of bascules in use, undertook the task of removing the limitations above referred to by selecting of the available types that which promised greatest efficiency and by modifying the counterweighting mechanism in such manner as to reduce the cost without sacrificing efficiency. Determining upon the ‘fixed trunnion’ type as the most dependable, he substituted concrete for the cast-iron counterweights, effecting [sic] at once a saving in cost proportional to the relative cost of the two materials…

The counterweight is further supported by means of a rigid member termed a ‘counterweight link,’ one end being pivoted to the counterweight and the other to the fixed tower, forming the trunnion support. This link is parallel and equal in length to a line joining the main and counterweight trunnions forming the so-called ‘parallel link’ counterweight system, which obtains through all the various forms of the writer’s types of bascule… It will be evident that if the counterweight trunnions are correctly located it is immaterial where the actual center of gravity of the counterweight mass is located. It can either be located above the roadway, as just described, or below the roadway…without raising the center of gravity (i.e., the trunnions) of the structure as a whole.

The result in the case of the W. & L. E. bridge was a saving of approximately $20,000 in first cost and the ultimate adoption of concrete counterweight by all designers of both bascule and lift bridges. Although thus first applied in the overhead type of bridge in 1904, the pin-connected concrete counterweight was originally proposed by the writer for the underneath counterweight type of bascule in 1901 in a series of plans which became the subject of much discussion and which later were embodied in patent application No. 738,954, applied for in December, 1902, and issued September, 1903.”

Its span was 150 feet, and it opened in October 1905. Engineering News reported on the proposed design in 1904 as follows,

“The Strauss bridge is of the trunnion type, but differs from other designs in its arrangement of the counterweight, by which the use of cast-iron weights and watertight tail pits is dispensed with, thus reducing the first cost and maintenance expenses. The tail end of the bridge is made short enough to clear the water line, and at its extreme end are pins on which the counterweight is carried… A pair of braced links, pin-connected to the fixed portion of the bridge, guides the box, the motion of which is downward and forward as the bascule leaf opens. The action is that of a parallel link mechanism, in which the main leaf trusses, the links, the fixed portion, and the counterweight box are parallel and equal elements… It also permits the elimination of all curved structural work and track girders, which tends to greater economy in design, greater’ accuracy in shop work, and greater speed in construction and erection…

The builders of this bridge state that… the Wabash Ry. Bridge at Cleveland… the Strauss design proved its economy by having less material in both substructure and superstructure than was called for in any of the other designs of bascule bridges proposed by competing bidders.”

To sell his design, he placed a full-page advertisement of this bridge, and his patented ribbed concrete bridge, in the March 1906 issue of Engineering World: A Weekly Technical Journal of Civil, Mechanical, Electrical, Mining, and Architectural Engineering. This overhead counterweight trunnion bascule bridge was the first of its kind built by Strauss. In his later Album of Bridge Designs, he wrote,

“The illustration on the preceding page is a view of the first Strauss Bascule Bridge, erected in 1904, for the Wheeling & Lake Erie Railroad, at Cleveland, Ohio. It is a 150-foot single-leaf, single-track span, and represents the first marked advance in bascule bridge construction. Of its advantages the principal one was economy, due partly to the first application of concrete as a counterweight for bascule bridges. Up to that date, counter-weighting had been effected with cast iron or more expensive materials. The substitution of concrete involved novel means of supporting same, but the cost of concrete being (weight for weight) much less than that of cast iron, the resultant effect was a material reduction in cost, and it is a matter of record that in this first bridge a saving of twenty-five thousand dollars in construction cost was realized.”

He sold his idea for a bascule bridge rather than a swing bridge by making nine points. “In general, the advantages of the bascule over the swing may be summed up as follows:

- The center pier and draw protection of the swing bridge are eliminated. These are especially objectionable in narrow channel, causing eddying currents, hindering navigation, and obstructing the flow, while the draw protection, if not maintained, causes damage to passing boats, with resultant expensive lawsuits.

- Future addition of immediately adjoining bridges or additional track on either or both sides of existing bascule bridges is obtainable, which is impossible in case swing bridges are used.

- For small vessels, the bascule need only open far enough to give sufficient vertical clearance, whereas the swing bridge must be opened fully in any event. The reason for this is that the entire width of navigable channel must be clear to permit passage, which is obviously impossible if the swing bridge be only partly opened.

- As a corollary it follows that a quicker passage of vessels and resumption of traffic results than with the swing bridge.

- In a double-leaf bridge the bascule offers an effective barrier against highway traffic going off the roadway into the river, a class of accidents common with the swing bridge.

- The bascule can be erected without interruption to land or water traffic.

- The bascule does not encroach on adjacent property or docks and does not isolate the operator from shore when open.

- In railroad bridges, mitered rail joints can be used without the necessity of rail-lifting devices.

- All stresses are statically determinate, ordinarily in the swing bridge continuous beam action takes place.” [Note, in his first patent application, he had 18 claims to originality]

The Chief Engineer for the Wabash Railroad Company wrote, “I consider the bridge lately put up for the Wabash Railroad Company at Cleveland the cheapest and best lift bridge on the market today. It is so well balanced that it can be stopped in any position and will remain there after the brakes have been released. I cannot illustrate this better than by saying that the addition of two or three hundred pounds of weight in the counterweight box makes difference enough in the balance of the bridge to affect the electric current sufficiently to be indicated by the ammeter reading. I understand that the bridge has been looked at by many Engineers, and all those who are unbiased have declared it to be the best structure of its kind they have seen.”

With this bridge, modified over time, Strauss began his career as the leading designer and builder of bascule bridges. He wrote, “but not until two years after the completion and thorough demonstration of the W. & L. E. Bridge was the great economic advantage of the all-concrete counterweight recognized by the engineering profession, in general, and universally adopted for all types of lift bridges. The W. & L. E. design, while having rendered excellent service at Cleveland, has been superseded by later and more economical forms which the parallel link counterweight system has taken.”

In 1906, he won an international competition to design a monumental Bridge across the Inner Harbour in Copenhagen, Denmark, called the Knippel Bridge.

The double leaf bascule measured 106 feet 6 inches from operating pinion to operating pinion. When closed, the arch halves connected and the bridge acted like an arch bridge under live loading. It totaled 238 feet 10 inches in length with flanking plate girder spans. The decorated concrete counterweights were located between flanking ornamental towers and dropped down to stop traffic when the bridge was opened. This was a significant project and cost approximately $230,000.

He became a fierce enforcer of his many patents for bascule bridges and was successful in suing several major cities for bascule bridges built by others that he claimed infringed on his patents. These early bridges, along with his patents, made Strauss the leading designer and builder of bascule bridges that competed with the lift spans of J. A. L. Waddell and swing spans of Alfred P. Boller and others.

In August 1906, he linked up with the Wallace-Coates Engineering Company. Henceforth, Strauss would concentrate on the design and Wallace-Coats on the construction of the bridges. He went on to obtain 15 bridge patents, with the last two for the Golden Gate Suspension Bridge for which he was the Chief Engineer. The reader is urged to read Strauss’ online paper to the 2nd Pan American Scientific Congress 1917, Vol. 6, pages 304-322, in which he traces the evolution of his bascule designs.■