Gustav Lindenthal was chief engineer of the New York Connecting Railroad for many years. The length of his section was 3.38 miles long and extended from a point in the Bronx at the intersection with the New Haven Railroad to Stemler Street in Long Island City. The line from north to south crossed the Bronx Kill, ran over Randall’s Island, across the Little Hell Gate, across Wards Island and over the East River at Hell Gate, and then by a long viaduct to the southerly-most point of his Division. The largest of the three bridges on the line was the Hell Gate.

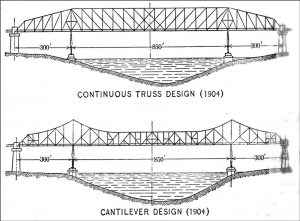

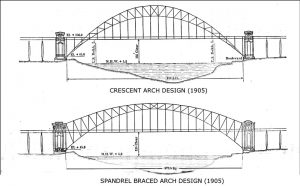

Lindenthal looked into several designs before arriving at the style of bridge he considered most economical for the site. He considered a stiffened suspension bridge with eyebar chains as he had earlier proposed for his North River, Quebec, and Manhattan Bridges; a three-span continuous truss bridge, like he built in Pittsburgh and had once considered for his North River Bridge; and a three-span cantilever bridge. Due to the heavy loading and sharp curves approaching and leaving the bridge, Lindenthal chose the arch design. He actually considered two competing steel arch designs. The first design was similar to Gustav Eiffel’s Garabit Viaduct in France. The second design, a flatter “spandrel arch,” had the lower chord begin at the bottom of the abutment while the upper chord began at the top. The latter design was inspired by similarly designed bridges over the Rhine River in Germany.

He prepared his preliminary designs from 1904 to 1905. In June 1907, Scientific American was running articles on the bridge with the headline, “The Largest Arch Bridge in the World.” The Engineering Record published a profile of the bridge and architectural treatment of the main piers at the same time. He was then planning to use steel towers and girders for his approach viaduct.

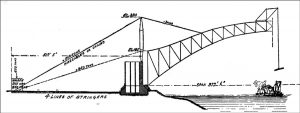

As was common with Lindenthal’s unique designs, he considered the erection procedure in detail, as the highest loads in the members frequently occurred during erection. He adopted a cantilever technique similar to that of James Eads on the St. Louis Bridge (STRUCTURE, December 2017). His method tied his cables/chains back to a deadman that was braced off four lines of stringers placed between the deadman and the bridge piers.

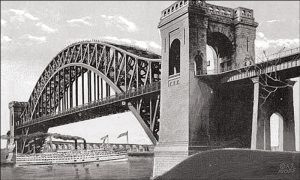

The Engineering Record wrote, “Besides planning a bridge of ample strength, the company has endeavored to make it a thing of beauty. Mr. Gustav Lindenthal designed the structure and associated with him was Mr. Henry Hornbostel, consulting architect. Mr. Lindenthal’s conception is that of an imposing portal, or gateway, from the Sound into the East River, just as the Brooklyn Bridge forms a gateway from the harbor.”

Between 1907 and the start of construction in 1912, Lindenthal made many changes in the design. He significantly modified his portal with an archway rather than towers on each side of the tracks. The change in the tower was the result of the Municipal Art Commission’s rejection of the plans. The New York Times reported, “Hell Gate Bridge Plans. Engineers Will Try Again to Please Municipal Art Commission…The original plans for the structure were rejected by the Municipal Art Commission on the single ground that the structural designs were not up to the aesthetic standard now required by the city.” O. H. Ammann, his assistant, wrote of the tower, “The commission, although not objecting to the design as a whole, disapproved of the decorative features of the towers and their bases.” The revised plans were not submitted to the Art Commission until May 29, 1911, and were finally approved on June 13, 1911. The original 1907 plan as noted called for steel girders and steel piers to be used on the viaducts, but Lindenthal changed to concrete piers as the prison authorities on Ward’s and Randall’s Islands “feared that inmates of the municipal institutions on those islands would climb them and make their escape. It was insisted that the design adopted should prevent this.”

His final design, completed with the help of David B. Steinman and Othmar H. Ammann, was for a 1,017-foot span bridge, 977 feet 6 inches center-of-skewback to center-of-skewback, between Astoria in the borough of Queens and Wards Island. At the time, this made it the longest and most heavily loaded railroad bridge with four (4) tracks in the world.

The project, along with more than 17,000 feet of approach spans and viaducts, also included an inverted bowstring truss bridge with four 296-foot 6-inch spans crossing the Little Hell Gate and a bridge of two 175-foot fixed trusses with abutting masonry arches across the Bronx Kill.

Hell Gate Bridge, Viaduct, Little Hell Gate Bridge (inverted bowstrings) foreground. Courtesy of HAER.

Lindenthal’s assistant, O. H. Ammann, wrote a lengthy 152-page paper on the project in the Transactions of the ASCE in 1918. The article had a 132-page discussion in which many leading engineers of the time, including Lindenthal, contributed. Most of them were very complimentary of Lindenthal and his design. One of the most significant things Lindenthal included was a program to measure stresses in his arch during construction under the guidance of D. B. Steinman. Steinman wrote a companion paper to Ammann’s entitled Stress Measurements on the Hell Gate Bridge in which he described measurements made on the structure to determine the accuracy of the computations. Steinman indicated that Lindenthal “certainly deserves all possible credit for his initiation of a public service in personally defraying the expenses of this investigation as a contribution to engineering science.”

The bridge opened in 1917. It continues to carry railroad traffic on one of the most heavily traveled rail lines in the country. Leon Moisseiff, in his discussion of Ammann’s paper, wrote, “The Hell Gate Bridge is an excellent example of what engineering genius can accomplish if the project is entrusted to one mind to plan and direct, unhampered by red tape and lay commissioners. The bridge reflects credit on the Engineering Profession, and much praise is due to Mr. Lindenthal and his able associates…” The bridge remained the longest arch bridge in the world until 1931 when Ammann opened his Bayonne Bridge with a span of 1,675 feet.

Ammann summarized the project as follows:

A great engineering work cannot be spontaneously created in its final, perfect form, but has to grow and develop gradually, in its entirety as well as in its constituent parts. Although the layman can only judge such a work in the light of an accomplished fact, the engineer must ever be conscious that it is only through extensive and laborious preliminary studies, and untiring efforts to improve, that he can hope to achieve a perfect work.

In the execution of a great and complex engineering or scientific undertaking, collaboration of experts in various fields is essential, but a great structure of monumental character must be the product of an individual creative and directive mind.

A great structure cannot be the result of a set of rules and specifications, nor of elaborate, mathematical computations. Such a work requires wide experience and sound judgment, and therefore, should be entrusted only to engineers of high professional attainments and reputation.

Throughout this paper, the importance of rigidity in bridge construction has been pointed out. Rigidity ensures greater durability and safety. There are remarkable examples of structures which have stood up under excessive strains under which they would have failed had it not been for the rigidity of their members or connections. Large bridges must be built for generations to come. Engineers to-day [sic] cannot afford to build important structures cheaply, to serve their purpose for the time being, and incur the risk of having to replace them after a short period of usefulness.

Emphasis has been laid on the appearance of the structures described. Engineering structures are still regarded by many engineers as mere works of utility, which deserve no consideration in architectural or artistic treatment. So long as this opinion prevails, the Engineering Profession will not lift itself to a higher plane, and it is even running the risk of being relegated to second place – or after the architect – in the creation of such monumental structures as properly belong in its domain.▪