Condensation on interior surfaces can cause corrosion and wood decay if not addressed promptly. Repair and restoration of decayed structural elements are important. Equally important is determining the source of the problem, so it does not reoccur. Condensation is moisture vapor collecting on a cold surface – in this case, wood roof sheathing at the interior of the building. This article presents a case study of an investigation on a tilt-up concrete warehouse with a low slope wood framed roof system, with insulation and vapor barrier located below the wood structural roof deck. The authors have found this construction type to be prone to condensation problems that can be related to small changes in interior temperature or humidity.

Case Study

Near Reno, Nevada, a 500,000 square foot single story warehouse was constructed in 2007. By 2012, large portions of the wood structural panel oriented strand board (OSB) roof sheathing was found severely decayed from moisture collecting on its underside. In 2013, Wiss, Janney, Elstner Associates, Inc. (WJE) was retained by an attorney representing the owner to evaluate and monitor moisture conditions at the underside of the OSB roof sheathing, as well as to design structural repairs.

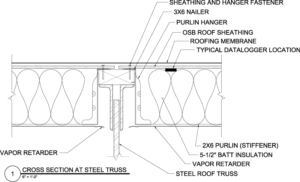

The subject building has 8-inch thick tilt up concrete walls, with the roof deck about 32 to 38 feet above the concrete slab-on-ground. The roof structure is wood panelized construction with steel trusses and steel columns. From the top down, the general roof assembly includes the following:

- Single ply thermoplastic roofing membrane attached via screws to the wood sheathing

- Separation sheet

- 15/32-inch thick OSB

- 2×6 lumber purlins at 2 feet on-center, spanning 8 feet

- Steel trusses at 8 feet on-center, spanning 50 feet

The roof is insulated with R19 fiberglass batt insulation placed below the OSB and between the 2×6 purlins, with a white vinyl vapor retarder stapled to the purlins below the insulation (Figures 1 and 2). The vapor retarder was not continuous and was not sealed around penetrations. The authors have studied similar warehouse buildings in Washington, Oregon, and California where the buildings are only provided with minimal heating systems due to their more temperate climates. Reno, however, can become frigid in the winter and more heating is required for interior comfort. This building is heated with eight direct-fired natural gas heating units. All of the combustion byproducts from the heaters, which includes water vapor, are blown into the interior warehouse space when the heaters are in use.

In 2012, during a tenant improvement, wet and decayed OSB roof sheathing was discovered. A subsequent investigation by others found that vast areas of the OSB had high moisture content and specific locations had advanced wood decay, causing localized loss of structural capacity (Figure 3).

Figure 3. TPO roofing cut open. Decayed OSB roof sheathing cannot resist penetration. Courtesy of Ray Wetherholt.

Moisture Monitoring at Roof Deck

To evaluate interior moisture, WJE obtained monitoring devices from OmniSense, LLC, which included two G3 Wireless Gateways and eleven S900 wireless temperature, relative humidity, and moisture content sensors (T+RH sensors). Ten T+RH sensors were installed inside the building, distributed throughout. At two locations, T+RH sensors were placed at 10 feet above the slab, just below the vapor retarder and at the bottom surface of the OSB. At the other locations, sensors were placed only on the bottom surface of the OSB. One sensor was placed outside to collect exterior temperature and humidity readings. The gateways collected data from the sensors wirelessly which was uploaded to the cloud via a built-in cellular modem. Real-time or archived data can be accessed from any internet connection. Data was collected for this project over a three-year period.

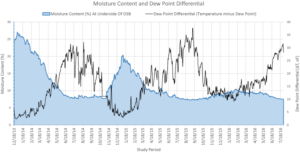

Figure 4. Approximate 3-year summary of moisture content and dew point differential conditions at the underside of the OSB roof deck.

The graph in Figure 4 shows a summary of overall trends over the three years. Data in Figure 4 shows an average value from the six sensors located on the underside of the OSB. The moisture content of sheathing in specific locations reached over 35 percent and lasted for a longer duration than indicated by the average. Figure 4 also shows a line defined as the “dew point differential,” which is the air temperature at the underside of the OSB roof deck minus the dew point temperature of the air at the same location. The dew point is the theoretical temperature at which moisture in the air condenses into liquid water. Condensation occurs when dew point differentials approach zero. The graphs illustrate that the incidence of higher moisture content in the OSB correlated with low dew point differentials. The growth of decay fungi in wood products can be prevented by maintaining a moisture content of 20 percent or less. Monitoring data shows periods of time in the winter months where moisture contents of the OSB exceed 20 percent.

Condensation Problems in Low Slope Roofs

In this particular building, the discontinuous vapor barrier allowed the relatively warm, moist air to contact the cold OSB surface, leading to condensation. In theory, a vapor barrier with low permeability that is sealed at all penetrations can act as an air barrier, preventing air movement to the underside of the wood deck. However, in practice, with the vapor barrier intersected by thousands of steel angle truss web members, there are too many discontinuities and penetrations to create an effective seal. The moisture added to the air by the direct-fired heating units, which increased the dew point temperature of the air and increased the severity and duration of condensation conditions, made condensation worse. Once the OSB is wet, the fiberglass batts adjacent to the OSB, as well as the vapor barrier, serve to trap the moisture and inhibit drying.

This problem is not unique to this particular building. The authors have seen similar problems in other wood panelized roofs with fiberglass batt insulation under the roof deck. Both APA and AITC have publications discussing the problem and ways to minimize moisture entrapment in panelized wood roof systems.

Structural Repair

A repair was implemented to restore the vertical and lateral load carrying capacity lost due to the decay of the wood roof sheathing. New plywood was placed over the existing OSB. The existing OSB was retained in place and allowed to dry. A new roofing membrane was then placed over the plywood. This was the preferred construction approach by the owner to minimize disruption to the tenant spaces below. An evaluation of the existing structural elements found that they had reserve capacity to accommodate the weight of the added 15/32-inch thick plywood roof sheathing and its fasteners. Screws, No. 8 x 2½-inch long (WSNTL from Simpson Strong-Tie), attached the new plywood to the existing framing and were designed to maintain diaphragm capacity. In this repair method, the plywood overlay only treated the symptom, so changes were also made to address the cause of the condensation.

Solutions

The methods of reducing condensation considered were: 1) reducing the amount of moisture in the interior air that is directly adjacent to the wood deck and 2) increasing the temperature of the wood deck. Reducing moisture in the air at the deck can be achieved by sealing or reinstalling the vapor retarder (which was impractical) or by making changes to the heating and ventilation system. Increasing the temperature of the OSB sheathing requires the installation of rigid insulation above it. Installation of rigid foam insulation on top of the wood roof sheathing was recommended by the authors but was ruled out due to cost.

The authors brought in Mechanical Engineer, Mark Scott, P.E. of MEP Engineering to evaluate and propose changes to the heating and ventilation systems at the buildings. In the summer of 2015, the direct-fired heating units were removed and replaced with indirect-fired heating units. The new heating units use a heat exchanger and exhaust the natural gas combustion byproducts, including water vapor, to the exterior of the building to maintain a dryer interior environment. As shown in Figure 4, this change significantly reduced the condensation and moisture build up in the wood roof deck during the winter months.

Conclusions

Condensation problems in a low slope warehouse roof can be severe and potentially cause significant problems for the structure. Severe decay in large areas of the wood roof sheathing was found in this case study building before the building was even five years old. Structural damage was repaired with a plywood overlay, and, through a thorough study of interior moisture issues, recommendations were offered to reduce the potential for future condensation. In the end, the condensation problem was solved by implementing changes to the heating system in the building by removing the direct-fired heaters and installing new indirect fired heaters that use a heat exchanger. This change was found to lower moisture content in the wood roof deck dramatically.▪

References

Wood Handbook–Wood as an Engineering Material, General Technical Report FPL-GTR-190, Forest Products Laboratory, Madison, WI, 2010, p. 14-6.

Guidelines to Minimize Moisture Entrapment in Panelized Wood Roof System, AITC Technical Note 20, February 1992.

Moisture Control in Low Slope Roofs, Form No. R525C, APA – The Engineered Wood Association, 2013.