Provisions for the design of cast-in-place and post-installed anchors were introduced into the American Concrete Institute (ACI) publication Building Code Requirements for Structural Concrete (ACI 318) in 2002 (ACI 318-02) via Appendix D – Anchoring to Concrete. Since ACI 318 is referenced in the International Building Code (IBC), these provisions are thereby incorporated into IBC Chapter 19 – CONCRETE.

Cast-in-place headed bolts and headed studs are generic products that can be used directly with Appendix D provisions. However, post-installed anchors must be qualified for use with the provisions of Appendix D due to the inherent diversity of adhesive and mechanical anchor products. For example, hybrid adhesives have different performance and behavioral characteristics versus epoxy adhesives. Likewise, epoxy adhesives can vary widely in performance due to differences in their chemical makeup, and in their installation requirements.

Given the wide array of post-installed anchor types and performance characteristics, ACI developed two standards to qualify these anchors for use with the Anchoring to Concrete provisions in the ACI 318 code. ACI 355.2 Qualification of Post-Installed Mechanical Anchors in Concrete was first printed in 2002. ACI 355.4 Qualification of Post-Installed Adhesive Anchors in Concrete was first printed in 2011. These standards serve as baseline provisions for two International Code Council Evaluation Service (ICC-ES) Acceptance Criteria: AC193 Acceptance Criteria for Mechanical Anchors in Concrete Elements (first printed 2002) and AC308 Acceptance Criteria for Post-Installed Adhesive Anchors in Concrete Elements (first printed in 2006). AC193 and AC308 contain programs to evaluate an anchor system for recognition under an IBC version adopted by a local jurisdiction. Design parameters and data from this evaluation are given in an ICC-ES Evaluation Service Report (ESR). Therefore, a post-installed anchor system evaluated per AC193 or AC308, having an ESR noting recognition under an IBC, can be designed using the Anchoring to Concrete provisions of the ACI 318 code.

In January 2015, ESRs for adhesive anchor systems began to list compliance with the 2012 IBC. There are changes with respect to the information contained in these reports compared to reports having recognition under previous versions of the IBC. This article explains what changes have been implemented into 2012 IBC-compliant adhesive anchor ESRs, and how these changes affect adhesive anchor design.

Review of the ICC-ES Acceptance Criteria AC308

The primary test programs for evaluating adhesive anchor systems in cracked and uncracked concrete are given in its Tables 3.1, 3.2 and 3.3 in AC308.

AC308 evaluation of adhesive anchor systems for design using threaded rods, internally threaded inserts and torque-controlled elements include various types of tests:

- reference tests establish the baseline bond strength of the adhesive

- reliability tests determine sensitivity to installation and load conditions

- service condition tests evaluate concrete conditions during the service life of the anchor, establish minimum spacing and edge distance requirements, and

evaluate performance in simulated seismic conditions.

Adhesive anchor ESRs based on evaluation per AC308 were first issued in November 2007, for recognition under the 2006 IBC. As such, an adhesive anchor system could be evaluated per AC308 and designed with the Anchoring to Concrete provisions of ACI 318-05 Appendix D. However, since ACI 318-05 Appendix D did not include provisions for adhesive anchor systems, AC308 was a stand-alone document that included a section titled 3.3 Strength design – amendments to ACI 318, which also contained equations and parameters for calculating bond strength in tension and concrete pryout strength in shear. The 2006 IBC-compliant adhesive anchor ESRs likewise began including these AC308 equations and parameters via Section 4.0 DESIGN AND INSTALLATION. Therefore, even though the scope of ACI 318-05 Appendix D did not include adhesive anchor systems, adhesive anchor design using Appendix D provisions could be performed via an ESR having 2006 IBC recognition. Adhesive anchor ESRs having 2009 IBC recognition also included the AC308 bond strength equations and parameters via Section 4.0, thereby permitting design per ACI 318-08 Appendix D. The ACI 318-11 code now includes adhesive anchor systems in Appendix D as referenced in Part D.2.2 – Scope, and ACI 355.4 is referenced in Part D.2.3 (d) as the standard to qualify adhesive anchor systems for use with Appendix D provisions. Part D.5.5 – Bond strength of adhesive anchor in tension contains provisions for calculating nominal bond strength in tension. Part D.6.3 – Concrete pryout strength of anchor in shear contains provisions for calculating nominal pryout strength in shear.

Harmonization Between AC308 and ACI 355.4

With the development of ACI 355.4 in 2011 to qualify adhesive anchor systems, ACI 355.4 and AC308 needed to be harmonized because ACI 355.4 will now serve as the baseline for AC308. Recall that AC308 was developed as a stand-alone document prior to the existence of ACI 355.4. Since adhesive anchor systems receive IBC recognition in an ESR via testing per AC308, the original AC308 provisions needed to be modified to coincide with the new baseline provisions of ACI 355.4. The significance of this is that the inclusion of adhesive anchor qualification and design provisions into the ACI 318 code has resulted in bond strength equations no longer being necessary in either AC308, or in adhesive anchor ESRs.

Beginning with 2012 IBC-compliant adhesive anchor ESRs (issued January 2015), bond strength equations are no longer included in the report because they are now given in ACI 318-11 Appendix D Part D.5.5. This means that adhesive anchor design under the 2009 IBC/ACI 318-08 or under the 2006 IBC/ACI 318-05 should also be performed using the equations of ACI 318-11 Appendix D Part D.5.5, because the original AC308 bond strength equations given in previous ESR versions are no longer presumed to be “code compliant”.

Comparisons between Previous Bond Strength Calculations

ACI 355.4 “prescribes testing and evaluation requirements for post-installed adhesive anchor systems intended for use in concrete under the provisions of ACI 318.” It includes test programs for evaluating adhesive anchor systems in cracked and uncracked concrete. Similar to AC308, the test programs in ACI 355.4 cover various conditions:

- reference tests to establish the bond strength of the adhesive

- reliability tests to determine sensitivity to installation and load conditions

- service condition tests to evaluate possible concrete conditions during the service life of the anchor, establish minimum spacing and edge distance requirements, and evaluate performance in simulated seismic conditions.

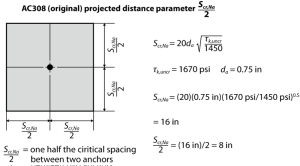

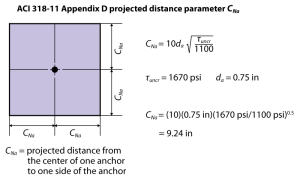

Although the ACI 355.4 test program is similar to the AC308 test program, it is important to note that ACI 318-11 Appendix D bond strength calculations, per the provisions given in Part D.5.5 Bond strength of adhesive anchor in tension, are based on parameters established in ACI 355.4. The D.5.5 calculation results will differ from bond strength calculations based on parameters previously established in AC308. The calculations for nominal bond strength per the original version of AC308, i.e. pre-ACI 355.4, used a parameter corresponding to the spacing between two adhesive anchors, scr,Na, and the equations for calculating nominal bond strength utilized either scr,Na or scr,Na/2. Nominal bond strength calculations in ACI 318-11 Appendix D are now based on a parameter corresponding to the projected distance from the center of an adhesive anchor to one side of the anchor, cNa, which does not equal the original AC308 value scr,Na/2. The value calculated for cNa is greater than that calculated for scr,Na/2. Figure 1 and Figure 2 illustrate why the original AC308 parameter scr,Na/2 differs from the new ACI 318-11 Appendix D parameter cNa.

Figure 1. AC308 (original projected distance parameter).

Figure 2. ACI 318-11 Appendix D projected distance parameter.

Looking at Figure 1, assume the characteristic bond stress (τk,uncr) equals 1670 pounds per square inch, and the anchor element consists of a ¾-inch diameter (da) threaded rod. The value for scr,Na calculated per the original AC308 Equation (D-16d) would equal 16 inches and the value calculated for scr,Na/2 would equal 8 inches. Looking at Figure 2, using the same values for τuncr and da, the value for cNa calculated per ACI 318-11 Equation (D-21) would equal 9.24 inches. Therefore, cNa is greater than scr,Na/2, which means ACI 318-11 Appendix D bond strength calculation results using cNa will differ from the original AC308 calculation results using scr,Na or scr,Na/2.

Adhesive Anchor Design Per ACI 318-11 Part D.5.5

Bond strength data published in 2012 IBC-compliant ESR tables titled BOND STRENGTH DESIGN INFORMATION is derived from adhesive anchor qualification testing per ACI 355.4/AC308, and is product-specific. This data is used to design the adhesive anchor system per the provisions of ACI 318-11 Part D.5.5. The parameter corresponding to the characteristic bond stress (τ) of an adhesive is a key parameter used in ACI 318-11 bond strength calculations. Values for τ given in the ESR bond strength tables are designated τk,cr for the characteristic bond stress of the adhesive in cracked concrete, and τk,uncr for the characteristic bond stress in uncracked concrete.

Characteristic bond stress (τ) is used either directly or indirectly in the ACI 318-11 equations (D-21), (D-22) and (D-27) to calculate cNa, the basic bond strength Nba, and the critical edge distance cac, respectively.

Another parameter relevant to the characteristic bond stress (τ) is the concrete temperature range. The ESR bond strength tables include a footnote that defines the concrete temperature ranges for which the adhesive has been tested. Temperatures corresponding to the “maximum short term” and “maximum long term” concrete temperatures for a given range are defined, and the characteristic bond stress (τ) values corresponding to these temperature ranges are given in the ESR bond strength tables. The concrete temperatures are defined in terms of “short term” and “long term”. Short term concrete temperatures are defined as “temperatures that occur over brief intervals, e.g., as a result of diurnal cycling,” and long term concrete temperatures are defined as temperatures that are “roughly constant over significant periods of time.”

The harmonization of AC308 with ACI 355.4 has resulted in some of the maximum short term temperature/maximum long term temperature values being increased. Characteristic bond stress (τ) values are correspondingly reduced as a result of these changes. ESRs that are 2012-compliant are the first ESRs to include these changes. Reference each ESR for changes specific to a particular adhesive anchor system.

Adhesive anchor ESRs having 2012-IBC compliance are used with the bond strength provisions of ACI 318-11 to design an anchorage in jurisdictions recognizing IBC 2012/ACI 318-11. Adhesive anchor design in jurisdictions recognizing previous IBC/ACI 318 versions should also utilize the ACI 318-11 provisions in order to be presumed “code compliant” because (a) the original AC308 bond strength equations have been removed from the ESRs, and (b) bond strength equations for adhesive anchor design are now given in ACI 318-11 Appendix D. There has understandably been some confusion regarding the requirement, and feasibility, of using ACI 318-11 bond strength provisions to design adhesive anchors in jurisdictions that have not yet adopted IBC 2012/ACI 318-11. Since AC308 (compliance January 15, 2015) no longer contains equations for calculating bond strength, use of the original AC308 equations given in pre-2012 IBC compliant ESRs needs to be justified by the Engineer of Record (EOR). When an ESR is updated, the previous version is no longer used unless justified by the EOR. Therefore, in order to be presumed code compliant, adhesive anchor design in jurisdictions still recognizing IBC 2009/ACI 318-08, for example, should be performed using the most current (2012 IBC-compliant) ESR and the ACI 318-11 equations unless justified by the EOR. Pre-2012 IBC ESR bond strength equations conflict with ACI 318-11 bond strength equations. Therefore, use of the pre-2012 IBC ESR bond strength equations must be justified for use in lieu of the equations now given in ACI 318-11.

Other anchor calculations, such as seismic calculations, will be based on the IBC/ACI 318 code version currently adopted by the jurisdiction because there is nothing in the 2012 IBC-compliant ESRs that conflicts with these code versions.

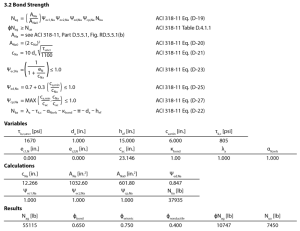

Figure 3. PROFIS anchor bond strength calculations.

Figure 3 shows calculations performed with Hilti PROFIS Anchor software using the data given in ESR-3187 (revised January 2015) for the HIT-HY 200 adhesive anchor system. Design using the seismic provisions of ACI 318-08 Part D.3.3.6 was selected. Besides the 0.75 seismic factor defined in ACI 318-08 Part D.3.3.3, Part D.3.3.6 requires an additional factor to be applied to non-ductile design strengths. The 0.75 seismic factor is shown below as [pmath]phi[/pmath]seismic, and the D.3.3.6 non-ductile factor is shown as fnonductile. Note that the calculations for nominal bond strength (Nag) are based on ACI 318-11 Part D.5.5, but the seismic calculations are based on ACI 318-08 Part D.3.3.3 and Part D.3.3.6. Therefore, the design strength calculations ([pmath]phi[/pmath]Nag) performed per ACI 318-08 Appendix D seismic provisions, and the nominal bond strength calculations (Nag) performed per ACI 318-11 Part D.5.5 are presumed to be “code compliant”.

Summary

ACI 318-11 Appendix D now includes provisions for calculating the nominal bond strength of adhesive anchor systems in Part D.5.5. Prior to ACI 318-11, adhesive anchor systems were not within the scope of Appendix D; however, ICC-ES developed the acceptance criteria AC308 to qualify adhesive anchor systems for recognition under the IBC, and to design adhesive anchor systems with the provisions of Appendix D. The original AC308 included provisions for calculating nominal bond strength since no provisions were available in Appendix D.

With the development of ACI 318-11 Part D.5.5, ACI developed a test standard, ACI 355.4, to qualify adhesive anchor systems for use with Appendix D provisions. AC308 has been harmonized with ACI 355.4, resulting in the only provisions recognized under the IBC for calculating bond strength being given in ACI 318-11 Appendix D. Revised bond strength calculations are now based on the projected distance from an anchor instead of the spacing between anchors. Characteristic bond strength values have also been revised per the changes in maximum short term/maximum long term temperature ranges.

Adhesive anchor design for pre-2012 IBC jurisdictions should use the provisions of ACI 318-11 Appendix D to be presumed “code compliant” unless justified by the Engineer of Record.▪