Structural engineering is one of those jobs where people joke, “if you see me running, try to keep up.” This may not seem dark until we experience tragedies like the recent Florida International University’s pedestrian bridge collapse or the Surfside condo collapse. In some ways, the phrase is meant to express the importance of what structural engineers do and the catastrophic consequences of failure. Fortunately, such events are exceedingly rare.

In general, the majority of the population does not know that structural engineers exist or at least do not understand what structural engineers actually do. If a structural engineer does their job correctly, it is not exciting. There are true structural emergencies, however, and there is a lot that we can learn from these emergencies. This article focuses on the decision-making process during a structural emergency. In this unique event, engineers and other team members necessarily streamline decision-making and remove many of the factors that are typically at play. Of course, money is always a concern, but it drops way down the list of priorities in a case such as this. This example also does not involve other engineering disciplines, so the structural engineer has full authority due to the critical and immediate nature of the event.

During a morning walk-through of a medical supply manufacturing facility in the rural United States, a plant worker noticed a large circumferential crack in the base of a 60-foot-tall, 6-foot-diameter, freestanding fiberglass industrial scrubber. A scrubber is a piece of equipment that facilitates chemical reactions to reduce emissions from industrial processes. In this case, the scrubber used sulfuric acid and was filled to approximately 15 feet. The acid in the structure has a pH of less than 1. The plant owner immediately acted and called a structural engineer to the site to investigate the crack and determine the stability of the structure. The owner also took proactive steps to shut down the plant, send all non-essential workers home, de-energize equipment within the fall radius, and make other general safety precautions.

Before the structural engineer was on site, he had already reviewed design documents, viewed pictures, and offered preliminary consultation to mitigate the risks of the hazard. For instance, the engineer recommended leaving the liquid in the scrubber since there were no visible leaks and it was likely serving as ballast, maintaining the stability of the structure.

Once on-site, the engineer assessed the surrounding structures for a suitable system to brace the tower. Each surrounding structure had to be evaluated, including creating analytical models and designing emergency bracing using only materials on hand. The team was fabricating the bracing on-site as the engineer was designing it and doing so around a potentially weakened structure; this was some of the highest-risk work required. The engineer also had to convey to the owner that this was emergency bracing and not a permanent fix. It was designed only to secure the tower until a hazardous materials team could drain the scrubber, and inspecting personnel could more safely approach the base to examine the crack. Given the urgency, it was not feasible to create a permanent system.

19 hours later, with the engineer satisfied that the bracing was sufficient, the team removed the insulation from the scrubber and determined that only the insulation was cracked. A further forensic investigation followed to determine the probable cause of the damage and give reasonable assurance that the tower would not experience further issues that could cause another shutdown or worse.

As for the decision-making, many of the typical design considerations were taken out of the equation. The goal was safety and reasonable certainty, not optimization, and the team was required to work quickly with only the materials on hand. Meeting code minimums was not the goal of design. With the limited time and information, the design utilized much more conservative loading. Cost was very far down the list of considerations. Authority was more concentrated in the structural engineer, as all stakeholders understood that with time and safety of the essence, decisions could be questioned later if necessary. Even with these typical roadblocks removed, the decision-making process was still difficult.

The owner informed the team that financial losses were in the millions for each day the plant was not operational. They rightfully shut down the entire plant once the crack was found, as the collapse of a 60-foot tower could have caused extensive damage, including rupturing gas lines and damaging electrical infrastructure, in turn causing fires. Industrial processes such as this also involve the controlled use of hazardous materials. The release of those materials could have immediate and long-term effects on the environment and the people in the area. The plant is integral to the economic livelihoods of local residents and critical to the medical supply chain, two factors that were both compounded by the global pandemic. Life safety was obviously the most immediate concern, but the local and global socio-economic impact was also considered.

Once the engineer and the contractors had adequately secured the tower, drained it, and removed its insulation, the engineer faced the ultimate decision of whether the tower was safe to operate. A second team was working on contingency in case the tower needed to be condemned. The best solution that the team could identify would be to close the plant for a minimum of two weeks. Stopping the medical supply chain for that long could create supply shortages. In addition, the plant has wide-reaching economic and social impacts, and a shutdown of such duration would have been detrimental to an area already struggling with the pandemic. The engineer had to consider all of this, along with the potential for injury or death if the tower failed after reentry into service. Had there been clear structural damage, the call would have been easy. In this case, there was no visible damage to the structure itself. The engineering team had to weigh all risks and make a judgment call based on available information.

How do engineers make such decisions, though? And how does ethics play a role?

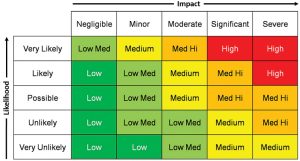

The public may be familiar with triage methods in the medical field or perhaps with risk management/mitigation practices in the business world. There are many methodologies for these assessments, but they all generally revolve around the same basic principles. A fundamental way of defining risk is to evaluate the impact of a potential outcome versus the likelihood that the outcome occurs. A simple risk management matrix looks like what is shown in the Table.

While still a judgment call, likelihood is generally based on data and experience. Likelihood, therefore, is more quantifiable and agreed-upon. In most regards, it is a stand-alone factor, and mitigation of likelihood can generally be approached by concrete identifiable measures.

Impact is where ethical considerations come into play. The impact varies based on several factors such as financial considerations, safety/human life, and overall economic consequences. Different cultures place different values on human life; some even determine that value based on age, gender, race, and socio-economic standing. In America, we tend to place a very high value on human life across the board. Financial impact is weighed differently by different stakeholders, as is the economic impact. These factors are more easily quantified in exact dollar amounts. However, how significantly those dollar amounts affect different people varies greatly.

Take OSHA regulations for fall protection as a concrete example. These regulations are based on the likelihood and severity of the injury. According to OSHA, the height at which fall protection is required is 4 feet for the general industry but increases to 6 feet for construction. Why are these different?

The simple answer is that construction workers accept greater risk. Four feet is the height at which the risk of significant injury greatly increases, 6 feet is the height at which the risk of death jumps up. This increase is one of impact. Are you more likely to fall from 4 feet than 6 feet under the same circumstances? No, so the likelihood is equal. We can mitigate the likelihood through training, physical barriers, etc., but if a fall occurs, then the impact is the same. This increased risk has been weighed against the necessity of workers performing tasks at such heights. Without this work, construction would be extremely difficult to complete, if not impossible. Therefore, the decision has been made to accept the greater risk.

As for the scrubber situation, based on the considerations listed earlier, most of which are not explicitly quantifiable, the team prioritized and addressed the risks and made final recommendations.

Immediate risk to human life is the top priority. The importance of financial impact decreases rapidly as safety risk increases since, for most individuals, life holds no quantifiable monetary value. The emergency bracing remediated an urgent safety risk and potentially limited damage to the facility. Once the safety risk was mitigated, the decision-making became more complicated. Trying to quantify and rank the successive priorities was challenging because the factors were not as clearly defined, especially while in the field with limited time.

Ultimately, with no visual evidence of damage to the structure and the economic, business, and other potential impacts, the engineering team decided that the structure could be put back in service for its limited remaining lifespan. However, the team also recognized that although no visual indications were present, the structure could still be under additional stress from the work that had caused the damage to the insulation. Since risk is a factor of both the likelihood and the impact, the owner implemented a monitoring plan to track the structure’s behavior so that plant management could promptly address worsening issues should they occur.

To be clear, this was an incredible team effort. It was one of those moments where egos were put aside, and different groups with otherwise different priorities came together for a clear common purpose. For structural engineers, lives are always on the line. In an instance such as this, the risks are more immediate and recognizable. Still, as those risks are addressed, the subsequent risks enter greyer and greyer areas where ethical decisions take a more significant role. Engineers are ultimately risk mitigators who are dealing with human life and livelihood. Therefore, every decision we make is a matter of ethics.■