The Silver Bridge across the Ohio River connecting Point Pleasant (West Virginia) and Gallipolis (Kanauga, Ohio) was opened to traffic on May 30, 1928, along with a sister bridge connecting St. Mary’s (West Virginia) and Gallipolis (Ohio), also across the Ohio River. It was called the Silver Bridge due to the color of paint used and was built just north of the intersection of the Kanawha River with the Ohio River. They were both vehicular bridges built as toll bridges by the Gallia County Ohio Bridge Company. The federal government’s approval was required, and bills were submitted to House and Senate for consideration. In December 1926, The Corps of Engineers informed the Bridge Company they must, in accordance with the act, submit a “plan of the bridge showing the length and height of spans; width of draw openings; position of piers, abutments, fenders, etc.”

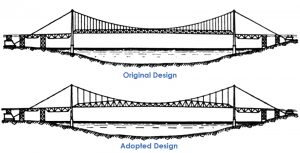

On December 29, 1926, plans were submitted to the Corps, which appointed a Board of Engineers to review them. After a public hearing, the Board recommended approval of the plans with minor revisions. The plans drawn by J. E. Greiner were for a conventional suspension bridge with wire cables, two lanes of traffic, and a sidewalk located inside the side trusses. On April 28, 1927, the American Bridge Company, which made the low bid, submitted plans for approval to the Corps. They were rejected as they did not conform to the approved plan. They submitted revised plans on May 2, 1927, which were approved. A new District Engineer took over and requested a set of plans and specifications for the bridge. In a letter accompanying the plans, Greiner wrote to the District Engineer,

“In accordance with your request, we are sending you a set of plans and specifications for the Point Pleasant Highway Bridge. The cable design calls for a straight wire cable. In asking for bids on the superstructure, two alternatives to this, namely, a long lay wire rope cable or heat-treated I-bars, may be bid upon. We expect to have these bids in within a short time, after which the type of cable will be decided upon, and we will forward you additional plans covering this part of the work.”

The Bridge Company selected the American Bridge Company to build the bridge using a chain made of eye-bars. Eye-bar suspension bridges had been built in Britain, starting with Thomas Telford, Samuel Brown, and Isambard Brunel. In the United States, James Finley was the first to use chains for his suspension bridges. Gustav Lindenthal became a proponent for iron chain bridges for his proposed North River (Hudson) Bridge, Manhattan Bridge (East River, NYC), and Quebec Bridges (St. Lawrence River). He proposed to build his bridges by stiffening the chains rather than the deck. In 1903, a Panel of Engineers selected to evaluate chains for the Manhattan Bridge determined, “the chains have a decided advantage in the accessibility of all parts for inspection and protection, [emphasis added] as well as in economy and rapidity of erection and they are to be preferred to wire cable whenever the cost of the chains is not materially greater.” Lindenthal was unsuccessful in having any of his plans for a chain bridge accepted. In 1922, H. D. Robinson and David B. Steinman were selected as design engineers for a bridge at Florianopolis (Brazil) to link the mainland with the island of Santa Catarina. Originally, they designed a standard wire cable suspension bridge. However, with pressure from the American Bridge Company (which had developed a new high strength eyebar) and the bridge owners, they changed their design to a chain.

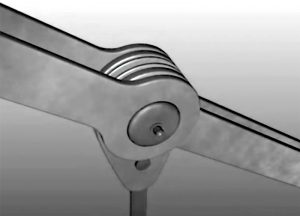

They also adopted Lindenthal’s pinned tower rocker bearings at the foot of the two-dimensional towers. There were four 2- x 12-inch bars per chain, and the main span was 1,113 feet 9 inches long.

The same thing happened at Point Pleasant, where the American Bridge Company convinced Greiner and the Bridge Company that a similar design was safe and less expensive than a conventional wire cable suspension bridge. American Bridge had used their eye bars on the Three Sisters Bridges across the Allegheny River in Pittsburgh between 1924 and 1928, using an alternating nest of nine and eight eyebars. They claimed their new “heat-treated carbon steel…would allow the individual members of the bridge to handle more stress.” Along with the two eye-bars sharing the load, the steel could easily handle the 4-million-pound load. The newly treated chain steel eye-bars had an ultimate strength of 105,000 pounds per square inch (psi) with an elastic limit of 75,000 psi along with a maximum working stress of 50,000 psi.

A huge pin passed through the eyes and linked each set of bars to the next. Each chain link consisted of a pair of 2- x 12-inch bars, and an 11-inch-diameter pin connected the links. The length of each link varied, up to 55 feet, depending upon its location on the bridge. With the higher strength of the steel, only two bars per panel, as noted, were required. Earlier chain bridges, both built and proposed, had many bars. For instance, Lindenthal’s chains for his proposed Manhattan Bridge had up to 20 links.

Construction of the Silver Bridge superstructure began in late 1927 and opened to a grand celebration on May 30, 1928. On June 21, 1928, the District Engineer made a final inspection and reported that the conditions of the permit “have been fully complied with and the work completed in substantial accordance with the approved plans.”

The bridge had side spans of 380 feet and a main span of 700 feet with short approach spans. The total length of the bridge was 1,750 feet.

On December 31, 1951, the bridge became a toll-free structure when West Virginia purchased it. Only cosmetic changes were made at the time of the purchase. Other major inspections were made in 1955, 1961, and 1965, all of which determined the bridge was safe. However, these inspections were visual-only, including the deck, trussing, and chain links. Since only the exterior surfaces of the links could be observed, there was no way of determining if corrosion, cracking, etc., of the interior, not visible, surfaces of the eyes were present.

Bridge Failure and Investigation

On a cold winter’s evening, December 15, 1967, the Silver Bridge collapsed into the Ohio River under a full load of Christmas shoppers, large trucks, etc. Observers stated, “the sound of the collapse was like that of a shotgun” and “the bridge just keeled over, starting slowly on the Ohio side and then folding like a deck of cards to the West Virginia side.” In an instant, sixty-four people in 32 vehicles fell into the river, and 46 of them died from drowning or being crushed by the falling bridge. After rescuing those they could and retrieving the bodies of those that died, the natural question arose as to how such an instantaneous collapse could occur.

The National Transportation Safety Board (NTSB) began its analysis shortly after the failure. One of the first steps was to remove the wreckage from the river and lay it out in a large nearby field for analysis. They found that the eye of one link had fractured, setting up a series of events that led to the failure. They issued an interim report on October 4, 1968, stating, “it was determined that the fracture in suspension chain eyebar 330 (north bar, north chain, Ohio side span) was essential to the catastrophic stage of the collapse, but the cause of the failure had not been determined…When the north eyebar chain was separated at joint C13N, total collapse of the bridge was a certainty due to its design with towers resting on rocker seats.”

In the final report (available online) issued on December 16, 1970, NTSB broke it up into four parts,

- A. With respect to the Sequence of Events in the Collapse of the Point Pleasant Bridge.

- B. With Respect to the Elements Which Contributed to the Failure.

- C. With Respect to the Implications for the Safety of Other Bridges.

- D. With Respect to the Status of Bridge Inspection and Maintenance.

In Part A, they had seven conclusions, five of which are given below.

- The total collapse of the structure required the failure of some element in the supporting chains or towers. The directions in which the towers fell indicate that this failure was at the Ohio tower or west of this point in the Ohio side span, and in the north chain or its supporting elements.

- Examination of the Ohio tower wreckage showed no failure in the north leg, and the laboratory examination of the fractures in the Ohio north chain bent post and gusset plate U7N showed these fractures to have occurred from excessive or abnormal loads beyond those which were possible from the loading on the structure just prior to collapse. The only remaining failure in the chain or its supporting elements in the Ohio side span, which could have led to collapse, is a failure of some element in the chain itself.

- The joint at C13N, the first joint in the north chain west of the Ohio tower, began to separate because of the brittle fractures in eyebar No. 330 (the northerly bar of the pair in the north chain connecting pins at joints C11N and C13N). Subsequent to this fracture, eyebar No.33 (the southerly bar of this pair) slid off the south end of the pin, causing complete separation of the north chain at this point.

- With respect to the brittle fracture in eyebar No. 330, the laboratory work has shown that:

a) The small crack which existed prior to the collapse was large enough to account for the brittle fracture in the special steel of which the eyebars were made at the stress level computed to exist at this location, without any additional dynamic effects.

b) This small crack probably initiated at a small corrosion pit.

c) The crack grew to critical size by the joint action of stress-corrosion cracking and corrosion fatigue. The available evidence is not sufficient to permit a definite conclusion as to which mechanism was predominant. - The small size of the critical crack in eyebar No. 330, and its location on the inside surface of the hole, precluded it being found while the structure was intact by the inspection techniques used, or by any other inspection technique available at this time for use in the field on heavy structures, without disassembly of the joint.

In Part B, two conclusions stand out,

- The point of high stress was not accessible for inspection.

- The use of only two eyebars per link in the eyebar chain. This made the total failure of the chain inevitable once the fracture occurred in eyebar No. 330. Had there been three or more eyebars per link, there would have been the possibility that the failure of one bar would not have led to disaster.

NTSB concluded with Parts C and D promoting greater bridge inspection. This resulted in the passing of a part of the 1968 Federal-aid Highway Act, from which National Bridge Inspection Standards (NBIS) were adopted by the Federal Highway Administration (FHWA) on April 27, 1971. It requires that all public bridges with spans over 20 feet be examined every two years and, if they are considered to be at a higher risk, more frequently.

The Safety Board did not specifically assign blame to J. E. Greiner or the American Bridge Company. Lawsuits against the Federal Government were unsuccessful. Lawsuits were also filed against the West Virginia Department of Highways. Still, they were disallowed by the court that ruled, “the collapse could not have been anticipated or foreseen by the respondent in the exercise of reasonable care.” Lawsuits against American Bridge and Greiner were filed, and in August 1973, they agreed to pay $950,000 in a settlement. Although the bridge had served for 39 years without incident, many still blamed the engineer and contractor in the belief there was no equivalent of the Statute of Limitations for the bridge engineer. The engineer must, it seems, within the bounds of economics, build for the ages.

Lessons Learned

Conclusion #5 has since been partially addressed with the availability of many non-destructive testing techniques that might have identified the crack if used on the Silver Bridge. The discovery of the crack probably would not have saved the bridge but could have prevented the loss of life. The most significant positive result of the failure was the creation of the National Bridge Inspection Program, which has identified many bridges that were failing or likely to fail in the future if no corrective action was taken.

Most engineers learn in college that a chain is only as strong as its weakest link. One statement of the Board that pertains to this truism is, “The designer, therefore, must be careful in deciding which influences should be assumed to occur simultaneously and must make appropriate reductions in the factor of safety for highly improbable conditions.” With only two bars in each link, it could be asked, did the designer take into consideration “highly improbable conditions” such as the failure of a single bar in a single link? This is sometimes called the What If question.

The collapse also led to the closure and demolition of the St. Marys Bridge as a safety measure. Engineers could not assure the public that the same thing would not happen to it as had happened to the Point Pleasant Bridge. A replacement for the Point Pleasant Bridge, a cantilever span, was completed one mile downstream in 1969 and is called the Silver Memorial Bridge.■