A bridge had been proposed across the St. Lawrence river for many years when the Phoenix Bridge Company and Theodore Cooper were selected to build an 1,800-foot-span cantilever bridge. The span would be the longest cantilever in the world, surpassing the Firth of Forth Bridge with its two spans of 1,710 feet. Cooper was initially selected as a consultant to the Quebec Bridge & Railway Co. to recommend a design from the many submitted in a design competition. He selected the Phoenix Bridge design as it was “an exceedingly creditable plan from the point of view of its general proportions, outlines, and its constructive features” and was the “best and cheapest plan and proposal of those submitted to me…”

At the time, Phoenix Bridge was one of the leading bridge companies in the world, and Cooper had an unblemished record as a bridge engineer. The original proposal was for a 1,600-foot cantilever, but Cooper recommended that the central span be increased to 1,800 feet to save the time to build and the cost of the piers.

On November 19, 1900, Cooper was retained as Consulting Engineer, and, shortly after, the Bridge Company received financial support from the Government. Peter Szlapka, working under J. Sterling Deans, started the actual design in accordance with specifications prepared by Cooper. Cooper had significantly modified the standard Canadian specification, placing his mark on the bridge. Two of the changes were,

- A reduction in wind load. The Original specifications used the Firth of Forth pressure of 56 pounds per square foot. This pressure was adopted after the Firth of Tay Bridge had failed under high wind loads. Cooper reduced the load to 30 pounds per square foot.

- An increase in the allowable working stresses in the members to 21,000 pounds-per-square-inch under a Cooper E-30 loading and 24,000 pounds-per-square-inch under a Cooper E-50 loading over the entire length of the bridge. At the time, the usual value was 16,000 psi.

Cooper loading E30 designates that each of the driving wheels has a load of 30,000#. It also specifies a load on the leading truck and another load on the trailing axle, plus a load for the following freight cars. At the time of the bridge’s design, a loading of E20 was common, but Cooper specified a loading of E30.

All the plans prepared by Szlapka were forwarded to Cooper for his review and approval. While the foundations were being placed between 1899 and late 1903, the design of the superstructure proceeded, and the anchor spans were approved in October 1904. Construction started on the south anchor span in July 1905, and the design of the south cantilever arm followed. Szlapka then determined that the fabricated weight of steel was coming in much greater than he had estimated. It so happened that he had not increased the estimated dead weight of his cantilever arm and suspended span in going from the 1,600-foot span to the 1,800-foot span that he used to design his anchor arm. Cooper knew that, short of taking the bridge apart, he could do nothing about it and wrote, “I made an estimate of the increased strains due to this increased weight and found it to be about 7 percent…Realizing that there was no remedy and that this 7 percent was not a fatal increase.” Szlapka then designed the cantilever arm and suspended span to the increased dead weight.

After the cantilever arm was finished, a smaller traveler was built to erect one-half of the suspended span. In early August, the splice in the lower chord 7-8L of the anchor span showed increased signs of distress. Cooper later stated that he began to get “uneasy” about the lower chord members on August 8 when he got a report from his man on the job, Norman McLure, on apparent bending of the web plates on the lower compression chord near the southerly pier.

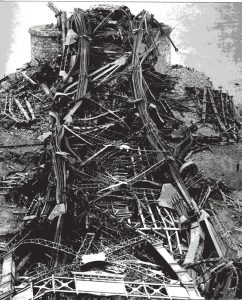

At the time of the collapse, the first three panels of the suspended span were in place.

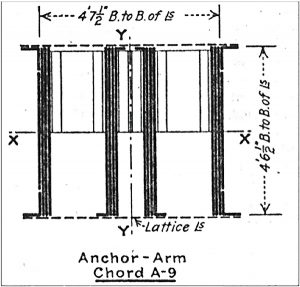

The outside ribs on A9L were each built up of 3 plates – 54 inches × 15⁄16 inch and one 37¾ inches × 15⁄16 inch combined with stich rivets. The interior ribs were built up with 2 plates – 54 inches × 15⁄16 inch and two 46 inches × 15⁄16 inch also connected with stich rivets. The ribs were separated by latticing top and bottom and diaphragms near the top. The ends of the plates were milled, and the compressive load between the members of the lower chord was to be transferred from member to member by bearing. However, during erection, they encountered many problems bringing the members into full bearing over the entire joint.

Between August 7 and August 27, 1907, there were many letters, telegrams, and telephone calls between McLure, Cooper, Szlapka, and Deans regarding the increased bending of the web plates of the lower chord. At first, many of the players believed the bend had been in the plates from the beginning. McLure could not convince them that the bend was not there initially and was increasing over time as more load was added to the suspended span. Some of the Phoenix Bridge men on the job, including Yenser, the foreman, believed the situation was critical. Birks, the Superintendent, continued to believe the bend was in the member from the beginning. McLure wrote to Cooper, “…although a number of the chords originally had ribs more or less wavy, as I have reported to you from time to time, it is only very recently that these have been in this condition, and their present shape is undoubtedly due to the stress they are now receiving. Only a little over a week ago, I measured one rib of the 9-L chord of the anchor arm here shown, and it was only ¾ inch out of line. Now it is 2¼ inches.”

McLure took the train to New York, arriving on the morning of August 29, and reported in person to Cooper on his concerns about the safety of the bridge. Finally recognizing the critical nature of the problem, Cooper told McLure to telegraph Phoenix Bridge, telling them to stop work immediately and sent him to Phoenixville to discuss the matter more fully with them. The telegram was sent at 12:16 PM and arrived at Phoenixville at 1:15 PM. McLure would not arrive at Phoenixville until 5:30 PM. At that time, the bridge collapsed into the St. Lawrence River, killing 75 men.

Harper’s Weekly asked, “was it properly constructed? Was the iron of inferior quality? Is there no method of making iron bridges of assured safety? And who is responsible (so far as responsibility goes) for such an accident – the engineer who designed the bridge, or the contractor, or the builders, or the railroad corporation? Was the bridge when made the best of its kind, or the cheapest of its kind.” A massive study was made by a Royal Commission, including a report by C. C. Schneider. They concluded, in part:

a) The collapse of the Quebec Bridge resulted from the failure of the lower chords in the anchor arm near the main pier. The failure of these chords was due to their defective design…

c) The design of the chords that failed was made by Mr. P. L. Szlapka, the designing engineer of the Phoenix Bridge Co.

d) This design was examined and officially approved by Mr. Theodore Cooper, consulting engineer of the Quebec Bridge & Railway. Co.

e) The failure cannot be attributed directly to any cause other than errors in judgment on the part of these two engineers.

f) These errors of judgment cannot be attributed either to lack of common professional knowledge, to neglect of duty, or to a desire to economize. The ability of the two engineers was tried in one of the most difficult professional problems of the day and proved to be insufficient for the task…

i) We do not believe that the fall of the bridge could have been prevented by any action that might have been taken after August 27, 1907. Any effort to brace or take down the structure would have been impracticable owing to the manifest risk of human life involved.

j) The loss of life on August 29, 1907, might have been prevented by the exercise of better judgment on the part of those in responsible charge of the work for the Quebec Bridge & Railway Co. and for the Phoenix Bridge Company…

m) No one connected with the general designing fully appreciated the magnitude of the work nor the insufficiency of the data upon which they were depending. The special experimental studies and investigations that were required to confirm the judgment of the designers were not made.

n) The professional knowledge of the present-day concerning the action of steel columns under load is not sufficient to enable engineers to economically design such structures as the Quebec bridge. A bridge of the adopted span that will unquestionably be safe can be built, but, in the present state of professional knowledge, a considerably larger amount of material would have to be used than might be required if our knowledge were more exact.

o) The professional record of Mr. Cooper was such that his selection for the authoritative position that he occupied was warranted, and the complete confidence that was placed in his judgment by the officials of the Dominion Government, the Quebec Bridge & Railway Company, and the Phoenix Bridge Company was deserved.

C. C. Schneider, in his report, wrote of A9L, A9R, and some other members,

“Since, however, the lower chord members of the Quebec bridge are butt-jointed, they are neither continuous nor pin connected, and it is impossible to make the whole section bear uniformly under the various conditions of loading…

However, there is a deficiency in many of the compression members, as their connections, such as the latticing, are not sufficient to make the parts composing them act as a unit. The most pronounced defect in this respect exists in the lower chord members of the cantilever and anchor.”

While not emphasized in his report, in the opinion of many, these were the cause of the buckling and failure of members A9L and A9R.

The blame was placed primarily on Cooper and Szlapka, and The Engineering Record wrote on Cooper,

“It is seldom that the responsible engineer for any work, great or small, has more authoritatively or more effectively impressed his engineering judgment upon the work in his charge than in this case…Perhaps the most painful part of the evidence is that in which the Consulting Engineer makes the plea of impaired health for not exacting from both the contractor and the Quebec Bridge Co. certain requirements of design and plans in the one case and the necessary organization for the proper performance of the work on the other. Unfortunately, such pleas are admissions of official shortcoming: however much a man may feel the disability of ill health, they give him no relief from official responsibility…The Consulting Engineer makes a further point in his evidence that the fee he received was quite insufficient to enable him to maintain a proper office workforce for the discharge of the duties imposed upon him in his official capacity…When he accepted the fee, he accepted all of the responsibilities of the position. No engineer has any right whatever to consider his responsibilities lessened because his fee is not as large as it should be…”

One of the worst and most studied, this failure pointed to the need for meaningful peer review and the need for qualified inspectors, with authority, on major works. It is hard from the perspective of the early 21st century to understand why it was not clear that the lower chord compression members were failing in, and probably before, early August. Accepting that fact would have required the entire design team to recognize that they had made a serious design error, which was not correctable, and that the bridge was doomed to fail. In the early afternoon of August 29, they could not have saved the bridge, but they could have saved the lives of the 75 men who died in the collapse.■