Concrete has been used for thousands of years. Today, it is the most utilized construction material in the world. Modern concrete is so ubiquitous because of its unmatched compressive strength, fresh-state malleability, and long-term durability, as well as the global availability of raw material resources.

The use of concrete is not without its drawbacks. Cement production alone is responsible for 8% of global carbon dioxide (CO2) emissions. Numerous efforts within the cement and concrete industry have targeted reductions in the environmental footprint of concrete. Strategies such as the use of supplementary cementitious materials, like fly ash, slag, calcined clay, and other natural pozzolans, reduce embodied carbon and increase the service life of concrete materials. While companies such as Blue Planet and Minus Materials aim to produce aggregates from CO2, we are a long way off from achieving carbon neutrality for cement and concrete products.

At the University of Colorado Boulder, an interdisciplinary team of researchers took inspiration from nature to address the fundamental challenge of producing a carbon-neutral – or even carbon-storing – concrete. They asked, “Is it possible to ‘grow’ a concrete alternative instead? If so, could we keep it alive?”

Self-Healing Bioconcrete

An interesting crossover between biotechnology and concrete has been occurring over the past few decades. Self-healing concrete materials, which utilize microbially induced calcium carbonate precipitation (MICP), originated at the Delft University of Technology in the Netherlands and have since been the focus of extensive research worldwide. Self-healing concrete, in principle, is concrete designed to seal its own cracks. Bacteria capable of MICP are mixed into concrete along with the nutrients required for survival. As cracks form, the bacteria produce calcium carbonate minerals, which subsequently fill the cracks. This self-sealing approach could be particularly effective for preventing further exposure and subsequent corrosion of rebar, which is detrimental to the longevity of reinforced concrete structures.

While MICP is an effective crack-repair method for concrete, the local environment within concrete is very harsh. It does not take long for most bacteria to lose their ability to reproduce and produce minerals. In fact, less than 0.5% of the initial bacterial inoculum has been shown to last more than 30 days.

The Future

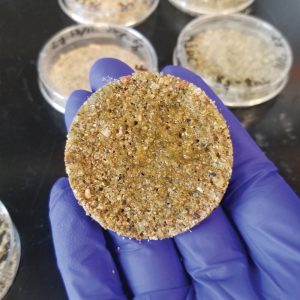

Led by Professors Wil Srubar, Sherri Cook, Jeff Cameron, and Mija Hubler at the University of Colorado Boulder, the interdisciplinary research team ‘grew’ portland cement-free concrete materials instead. In one of the approaches, researchers engineered a concrete-like material with an internal environment more suitable for microbes. In these living building materials (LBMs), photosynthetic marine cyanobacteria capable of MICP were encapsulated in a biocompatible, hydrogel-sand matrix. It was demonstrated that the minerals produced by the bacteria significantly improved the mechanical properties of the materials compared to bricks without cyanobacteria.

The result was a ‘grown’ composite material with a compressive strength (f´c) of approximately 500 psi – on par with a low-strength cementitious mortar and higher than that of adobe brick. Microbial viability within these materials substantially exceeds that of traditional self-healing concrete. Nine percent of the initial inoculum survived for 30 days in the cyanobacterial mortar. These mortars represent a new materials paradigm, in which microorganisms can participate in material manufacturing and persist within the resultant material, thereby imparting a biological functionality to an otherwise inert structural material.

Other Biological Functions

Maximizing long-term microbial viability opens the door for a multitude of biological functions to be engineered into structural materials, like carbon sequestration, chemical sensing and signaling, self-healing, and self-regeneration. In the University’s seminal work, successive self-regeneration was explored. Researchers took one brick, split it into two, fed it fresh nutrients, and effectively ‘grew’ two new bricks from one parent generation. This was accomplished two subsequent times so that one parent resulted in eight living child bricks. This study demonstrated that the manufacture of building materials does not have to be limited to making one steel beam or one concrete mix at a time. In the future, the manufacture of materials will be possible exponentially by harnessing the exponential growth of bacteria.

Initial Conclusions

The research efforts are only beginning to scratch the surface of possibilities. Other living organisms, for example, could impart a myriad of biological functionalities, like bioluminescence. Different bacteria species or co-cultures of bacteria could work together in a multifunctional way to self-regenerate, self-heal, and/or sense and respond to external stimuli, such as light, heat, pressure, and magnetism. If nature can do it, living materials can be engineered to do it, too.

Considering the challenges humans will face in the 2020s and beyond – climate change, disaster resilience, infrastructure, and space exploration – we should look to the power of biology and living materials at the building scale to help solve some of the most critical environmental crises of our time. By doing so, we could harness the ability of living organisms to create materials that would help us build more sustainable communities – both on earth and beyond – that better blur the boundaries and bring harmony to the built environment and natural world.■