Why Now and How Do You Use It?

The building and construction sectors play a vital role in minimizing our future carbon footprint. Each year, the built environment contributes almost 40% of global greenhouse (GHG) emissions. The industry’s focus on operational carbon reductions – the energy used to heat, cool, and power our buildings – has led to many successes. However, the attention to embodied carbon, the emissions associated with material production and construction processes, has been lagging.

Between now and 2050, embodied carbon will be responsible for an ever-increasing part of the total building and construction carbon emissions due to the rapidly improving carbon footprint of our energy grid. Not only will embodied carbon exceed the operational carbon footprints for new construction between now and 2050, the carbon being emitted at the start of a building’s life cycle is where the time value of carbon is often most important.

As part of a growing commitment to action on these issues, already demonstrated by the structural engineers SE2050 Challenge issued by the Carbon Leadership Forum (CLF) and endorsed by SEI’s Board of Governors, the Embodied Carbon in Construction Calculator (EC3) tool was created with input from a coalition of more than 50 forward-looking and innovative building industry leaders.

This article presents a strategy for including the EC3 tool in today’s design, procurement, and construction practices. Like design and construction today, there is more than one option for how the EC3 tool can be used and it is adaptable to a variety of use cases.

The EC3 tool is intended to supplement and improve, not to replace, current Whole Building Life Cycle Analysis (WBLCA) efforts. It targets improving the data considered at a critical stage within many WBLCA efforts when supplier procurement decisions are made. It makes material Environmental Product Declarations (EPDs) more accessible, easier to compare, and with their uncertainties better defined.

For the LCA experts reading this, the EC3 tool focuses on the Product Category LCA stages A1 to A3, or a cradle-to-gate material Environmental Product Declaration (EPD) embodied carbon evaluation. EPDs, for those wondering, are similar to “nutrition labels” that would come with a material, reporting environmental impact data on that specific material. While the EC3 tool does not attempt to address the other whole building LCA stages A4 through D, these other stages are each fundamentally important. Holistically evaluating all aspects of the building’s life cycle is critical to understanding the full implications of our choices (Figure 1).

Another long-term goal of this effort is to encourage this next generation database of EPDs, which includes statistical uncertainty evaluations of the EPD data, to be integrated into the current and future generation WBLCA tools being used. As a result, the EC3 tool is a free, open-access tool.

The EC3 tool initially focuses on these materials:

- Structure: Concrete, Steel, Timber

- Enclosure: Aluminum, Glass, Insulation

- Finishes: Carpet, Ceiling Tiles, Gypsum Wall Board

The EC3 tool’s information helps carry forward from what is estimated and measured by the design team into the contractor’s budgeting, procurement, and construction efforts, to support a double bottom line accounting process to analyze embodied carbon and cost.

Remember, though, that the EC3 tool is not conceived of as the final decision-making tool when deciding how to manage the carbon budget or procurement process. Instead, it makes embodied carbon information available at significant decision-making points of a project. It is only one part of a larger design and construction decision-making process.

The EC3 Tool Structural Use Case

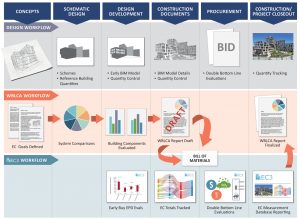

The flow diagram shown in Figure 2 describes how the EC3 tool integrates into the current design, procurement, construction, and close-out processes. A further breakdown of this process can be found at www.buildingtransparency.org/en. With this use case, there are several points to highlight.

For starters, make system and material decisions based upon the best value and materially efficient use as a starting point. Consider the use of lower carbon footprint materials wherever possible, but maintain an awareness of the best-value optimized design that meets the owner’s program and goals.

Why the focus on optimization and not carbon first? Considering the holistic impacts of where the material of a project comes from, how it is made or harvested, and if the design concepts are an optimized material use can often create a more significant swing in a project’s final carbon footprint than the choice of the initial material only. Picking what is perceived to be the lower carbon material is a good starting point, but it does not guarantee a low carbon design, especially when the material use is not optimized or not in an appropriate use case.

Also, when BIM modeling is started, decide if it is to be used for structural quantity material reporting (the best approach for the future), or if you plan to track quantities through a spreadsheet or rely on the contractor quantity estimates. However quantities are tracked, be consistent. The EC3 tool can accept direct imports from Revit through BIM 360 to simplify the importing of data, but you should always check any direct imports with a verifying sample hand calculation as well to know your Revit model and the EC3 tool are in alignment with how the data is being handled.

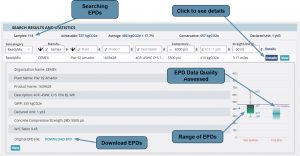

The EC3 tool includes both industry average EPD data, for an early reference building definition prior to the actual material suppliers being known, as well as North American vendor-specific EPDs to the extent they are known and published. This includes the National Ready-Mix Concrete Association’s (NRMCA) regionally averaged EPD data sets, the American Institute of Steel Construction’s (AISC) national average EPD’s for steel, and the American Wood Council (AWC) national average EPD’s for lumber. (Figure 3).

For any pre-determined, whole-project carbon budget targets, conservative to aggressive targets can be set from within the EC3 tool. A key feature of the tool is that EPD uncertainty and material variability is reported.

Note that when considering total variability reporting within a project, when materials are combined but only based upon industry average EPD data, it usually shows that definitive early project decisions comparing between one material or another are inconclusive or inappropriate based upon the material choice alone. Trend data is credibly shown, but the industry average uncertainty bars will often overlap. Therefore, making initial material decisions based upon the best-value optimized use is a sounder starting point than trying to compare non-compatible industry average LCA data and getting faulty findings because of it.

Specification language to support the asking for and tracking of vendor-specific EPDs also should be incorporated at the earliest stages possible. The Carbon Leadership Forum provides sample specification language that can be used for this purpose. Similar language has also been posted at the newly formed BuildingTransparency 501(c)3 web site, https://bit.ly/3foW9rf, which has become the specific host of the EC3 tool as an outgrowth of the Carbon Leadership Forum’s incubation of the EC3 tool.

Using performance targeted LCA specifications that ask for vendor-specific EPDs within the project materials often leads to detailed discussions on embodied carbon reduction strategies up and down the supply chain. By asking for EPDs and letting this reporting tell the material embodied carbon data story, the vendor is open to select their own strategy for how they choose to compete on this issue. A successful strategy is to telegraph intentions to potential material suppliers well in advance of the actual ask, to allow them to organize around the topic before the time of the bid.

As the use of vendor-supplied EPDs grows, it will become easier to follow this process. It is currently the easiest to compare this data for West Coast U.S. cities, but the trend to make EPDs available is happening nationally. Being wise to the market variability of a project’s location and engaging the full project team early in the process is the key to success.

It is notable how fast the topic of embodied carbon EPD reporting is moving across the industry and the nation. When motivated large project development clients express an interest in this information, and they are requesting double bottom line accounting, regional material suppliers respond. From the time of the EC3 tool’s conception to its November 2019 launch, the number of available EPDs within the concrete industry alone grew to over 23,000 within the EC3 tool.

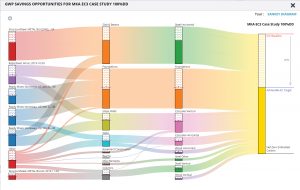

Structural sub-contractor bids containing material quantity assumptions, cost, and EPD embodied carbon information is where the EC3 tool becomes most valuable, and where things all come together (Figure 4).

The EC3 tool calculations can and should be updated based on the subcontractor’s data collected during the bidding process. Decisions between like materials can then be made, choosing where and when to pursue aggressive embodied carbon targets. This can happen with due consideration of other project goals around schedule and cost, while still looking to stay within an overall embodied carbon project budget. Any schedule or cost premiums, if they exist, can be evaluated against the benefit of the embodied carbon reductions. This allows a more informed decision-making process to occur, lower embodied carbon material suppliers to be identified, and best value trade-offs to be considered in the award of that project scope.

It is typically a very competitive marketplace for material suppliers. The variables that are tracked and paid attention to at the time of bidding are something suppliers cannot help but look to optimize and differentiate around. This is one of the crucial ways that the EC3 tool is helping to move the industry to a lower embodied carbon future for construction.

The EC3 tool, within its data collection and reporting, has a portal for uploading project data, anonymizing the information to the level the user putting in the data desires, and publishing it as part of an ever-growing database of verified building embodied carbon reference buildings. As noted earlier, this reporting can also help support initiatives such as the SE 2050 Challenge (https://se2050.org). As the EC3 tool’s project database grows, primarily when populated with as-built project data, the collective ability to better define reference buildings and starting points for what is possible will result in mutual, shared benefits.

Conclusion

We all have a stake in improving how the industry moves toward a lower carbon footprint of construction. The design and construction communities are in a unique position to define the process for evaluating embodied carbon and can utilize the supply chain process to deliver more low-carbon material options. The EC3 tool’s use encourages project teams to set a “carbon budget” during design and consistently manage it through material “quantity control” and procurement efforts that are later validated during the construction process. The authors invite fellow structural engineers to adopt this vital tool. The current use of the EC3 tool among team members and collaborators has already delivered demonstrated impacts on reducing the embodied carbon footprint in the building industry.■

Reference

Whole Building Life Cycle Analysis stages per EN 15978, from LCA of Buildings: A Practice Guide3.3 Carbon Leadership Forum, “Life Cycle Assessment of Buildings: A Practice Guide,” 2018, https://doi.org/http://hdl.handle.net/1773/41885.