(STRUCTURE magazine, August 2018, by Sompandh Wanant)

The August 2018 STRUCTURE article, Unanticipated Stresses and the Welded Flange Plate Moment Connection, presents information and opinions on welded steel moment connections and more specifically on connections in the standard ANSI/AISC 358-16, Prequalified Connections for Special and Intermediate Steel Moment Frames for Seismic Applications. Some of the information in this article may be potentially misleading, particularly regarding statements made on vertical beam shear distribution and weld shrinkage residual stresses. These issues are addressed below.

Vertical Beam Shear Distribution

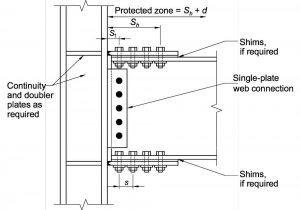

Mr. Wanant notes in his article that the common assumption that the beam web connection transfers the shear and the beam flange connections transfer the moment is not accurate. Mr. Wanant is completely correct in this observation. The fact that much of the beam shear is transferred by the flange connections is well recognized based on post-Northridge earthquake moment frame connection research and is well recognized in the prequalification of connections for ANSI/AISC 358.

A number of researchers have concluded, based both on experimental evidence and on finite element simulations, that substantial shear is transferred to the column through the beam flange connections. (See, for example, El-Tawil et al. 1998, Lee et al. 1997, Uang et al. 2000). Further, the distribution of shear between the beam web and flanges near the face of the column depends on the connection details, is different in the elastic and inelastic ranges of behavior, and differs depending on the degree of inelastic rotation sustained by the beam. The formulas suggested by Mr. Wanant to predict the distribution of shear between the beam web and flanges (Eqn. 1 and 2 in the article) are based on elastic analysis and therefore are not valid in the inelastic range of behavior. Connection behavior in the inelastic range is of greatest interest in seismic design and the prequalification of connections for ANSI/AISC 358. Further, even in the elastic range of behavior, Eqn. 1 and 2 do not correctly predict how much shear is carried by the beam flanges at the beam-to-column connection.

It is well understood from research that the beam flanges transfer a large portion of the beam shear at welded beam-to-column connections. It is also understood that the shear in the beam flanges not only adds shear stress to the beam flanges but also generates secondary bending stresses in the beam flanges. Additional complexities occur in the state of stress in the beam flanges near the face of the column due to column flange bending and due to the influence of weld access holes. These issues have also been extensively studied in research. Nonetheless, despite the complexities in the state of stress in the beam flanges near the face of the column, research and testing have also shown that welded beam-to-column connections can develop very large cyclic ductility, if properly designed and detailed. ANSI/AISC 358 provides the needed guidance to design and construct beam-to-connections capable of providing satisfactory seismic performance. It would be incorrect to infer that issues such as shear in the beam flanges have somehow been overlooked by the research community or have been overlooked in the development of prequalified connections in ANSI/AISC 358.

Weld Shrinkage Residual Stresses

Mr. Wanant notes in his article: “Although both the RBS and WUF-W are prequalified by laboratory testing, the validity of the testing is questionable since it did not represent the actual building frame construction. In preparing the test specimens, there was no external restraint in the welding of beam-to-column specimens or the cyclic loading tests.”

Most moment frame connections are tested using specimens constructed with an approximately 10- to 20-foot segment of a beam connected to a column. Mr. Wanant is correct that no external restraint is normally applied at the free end of the beam during welding. However, it is incorrect to assume this invalidates these tests. Zhang and Dong (2000) conducted a computational study of welding residual stresses in welded moment frame connections. In their study, they computed residual stresses in a simple butt-welded joint where the plates had no external restraint. They also computed residual stresses in a weld connecting a beam flange to a column, where the beam flange was completely restrained against horizontal movement a short distance from the weld, representing a more severe condition of restraint than found in actual construction. Both cases, with or without external restraint, showed very high, yield level residual stresses in both the longitudinal and transverse directions, along with significant triaxiality. These results suggest that the external restraint is not needed to generate high welding residual stresses. Rather, local effects, which are well represented in moment connection test specimens, provide restraint leading to high residual stresses. For example, in the multi-pass welds used to connect a beam flange to a column, shrinkage of each pass is restrained by the previous passes. Further, differential cooling of a weld pass across the width of the beam flange will generate large residual stresses even in the absence of external restraint to the beam, since the portions of the weld that cool first will restrain the portions of the weld that cool later, for the same weld pass.

Studies on the impact of welding residual stresses on the behavior of welded moment connections were conducted by Chi et al. (2000). In their study, they used the residual stresses computed by Zhang and Dong (2000) for the case in which the beam flange was completely restrained. Their research showed these residual stresses increase the fracture toughness demand on the beam flange welds and can reduce the fracture strength of the connection in the presence of low-toughness welds, as was the case for pre-Northridge connections. However, the high level of fracture toughness required in post-Northridge welded moment connections, combined with improved detailing and inspection requirements, provide substantially improved protection against premature brittle fracture in beam flange welds and make these welds highly tolerant of large residual stresses.

In summary, it is misleading to suggest that tests used to prequalify moment connections for ANSI/AISC 358 are not valid on the basis of welding residual stresses. Further, as described above, current requirements for welding, detailing, and inspecting moment frame connections provide robust welds with a high tolerance for residual stresses.

In his article, Mr. Wanant also states: “The Bolted Flange Plate (BFP) moment connection (Figure 2) employs the flange plates as connecting elements, and the plates are free to move when welded to the column; therefore, only minor residual stress exists at the welded joint and may be considered negligible.” Based on the research by Zhang and Dong (2000) described above, very high residual stresses would be expected in the welds that connect the flange plates to the column in the Bolted Flange Plate Connection, and certainly should not be considered negligible. Consequently, designers should not relax requirements for welding, detailing, and inspection for the Bolted Flange Plate Connection based on a belief that welding residual stresses are negligible in this connection.

Welded Flange Plate Connection

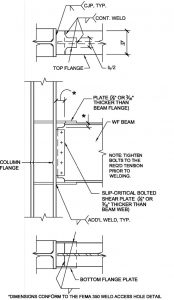

In his article, Mr. Wanant indicates that the Welded Flange Plate (WFP) connection should be considered for prequalification, but that has not yet been tested for prequalification. The WFP connection was tested as part of the FEMA/SAC project, and is included in FEMA 350, Recommended Seismic Design Criteria for New Steel Moment-Frame Buildings (FEMA 2000). Note that a number of details of the WFP connection in FEMA 350 differ from those shown in Figure 3 in Mr. Wanant’s article. Designers with interest in the WFP connection are referred to FEMA 350 for suggested design and detailing rules. Note, however, that the WFP connection has not yet been prequalified in ANSI/AISC 358.

The AISC Connection Prequalification Review Panel (CPRP) is responsible for prequalifying connections for inclusion in ANSI/AISC 358. The CPRP, in turn, follows the requirements for prequalification specified in Chapter K of ANSI/AISC 341-16, Seismic Provisions for Structural Steel Buildings. The AISC CPRP welcomes new connections for possible prequalification and has prioritized connections based on the strength of available prequalification data and based on industry demands. As described above, a limited number of tests were conducted on the WFP connection by Kim et al. (2000), and it is unclear if this test data is sufficient to support prequalification. However, the CPRP may consider the WFP connection for prequalification in the future.

Closing Remarks

The prequalified moment connections in ANSI/AISC 358 have undergone extensive testing supported by computational and analytical studies. The development and prequalification of connections for ANSI/AISC 358 is informed by the extensive body of research on moment connections conducted after the 1994 Northridge Earthquake, including research on shear in beam flanges, welding residual stresses, and host of other issues. While there are certainly needs for additional research, the existing body of knowledge on moment connection behavior for seismic applications is very strong, and designers can have confidence that the connections in ANSI/AISC 358 will provide robust behavior under seismic loading.■

References

Chi, W-M., Deierlein, G. and Ingraffea, A. 2000. “Fracture Toughness Demands in Welded Beam-Column Moment Connections.” Journal of Structural Engineering, ASCE, V. 126, No. 1.

El-Tawil, S., Mikesell, T., Vidarsson, E., and Kunnath, S. 1998. “Strength and Ductility of FR Welded-Bolted Connections.” Rep. No. SAC/BD-98/01, SAC Joint Venture, Sacramento, Calif.

FEMA 2000. Recommended Seismic Design Criteria for New Steel Moment-Frame Buildings. FEMA 350, Federal Emergency Management Agency, Washington, DC.

Kim, T., Whittaker, A.S., Bertero, V.V., and Gilani, A.S.J. 2000. Steel Moment-Resisting Connections Reinforced with Cover and Flange Plates. Report SAC/BD-00/27, SAC Joint Venture.

Lee, K-H, Goel, S.C. and Stojadinović, B. 1997. Boundary Effects in Welded Steel Moment Connections, Research Report UMCEE 97-20, The University of Michigan, Ann Arbor, MI.

Uang, C-M., Yu, Q-S., Noel, S., and Gross, J. 2000. “Cyclic Testing of Steel Moment Connections Rehabilitated with RBS or Welded Haunch.” Journal of Structural Engineering, ASCE, V. 126, No. 1.

Zhang, J. and Dong, P. 2000. “Residual Stresses in Welded Moment Frames and Implications for Structural Performance.” Journal of Structural Engineering, ASCE, V. 126, No. 3.