The First Cast Iron Bridge in the United States

Masonry arch bridges date from 1,300 BC, but it was the Romans who developed the form for bridges, aqueducts, and buildings. Many of them, like the Pont du Gard Aqueduct, circa 50 AD, still stand after almost two millennia. Cast iron arch bridges were built in England starting in 1779 with the Coalbrookdale Bridge across the Severn River, which still stands. Later, Thomas Telford built many cast iron arch bridges. His first was the Buildwas Bridge just upstream from the Coalbrookdale Bridge. Many of his bridges are still in service. The French built several iron bridges across the Seine, most notably a pedestrian bridge, the Pont des Arts, in 1804. The French engineer A. R. Polonceau built the Pont du Carrousel over the Seine in 1834 with cast iron tubular arches and a span of 150 feet. In the United States, James Finley used wrought iron links for his chains and suspenders in his early suspension bridges. Theodore Burr used wrought iron chains in some of his early wooden arch/truss bridges.

Old view of the bridge, with Brownsville on the right from Sherman Day’s Historical Collections of the State of Pennsylvania.

Captain Richard Delafield was assigned the task of upgrading the National or Cumberland Road east of the Ohio River in the early 1830s and given a budget of $300,000 to do so. The road was built between 1811 and 1833, generally with masonry arch or wooden bridges. The states through which it passed (Maryland, Virginia, Pennsylvania) agreed to take over maintenance of the road once the Federal Government repaired it to their satisfaction and built the required toll booths. There were two major bridges in Delafield’s section, one at Cumberland, Maryland, over Will’s Creek and the Dunlap’s Creek Bridge. A bridge on the road existed across Dunlap’s Creek in Brownsville, Pennsylvania, before 1794 and before the construction of the National Road. The bridge crossed Dunlap’s Creek separating Brownsville from Bridgeport, Pennsylvania, a short distance above where it merged with the Monongahela River. A wooden bridge at the site collapsed in 1808 and James Finley (STRUCTURE, November 2008), a resident of Brownsville, built one of his chain bridges at the site in 1809. It collapsed in 1820 under a load of snow and a six-horse team. A new wooden bridge was built by Isaac Core in August 1821. When Delafield arrived in 1832, the Core bridge needed replacement. Lt. Mansfield indicated it would not last another year. A four span covered bridge built in 1833 crossed the Monongahela River just upstream from the junction of Dunlap’s Creek and the river.

Delafield first argued that a bridge at the Dunlap’s Creek site preceded the National Road and that it was not the responsibility of the Federal Government to upgrade it. He was told to proceed but then suggested a different location that would make a better connection with the existing covered bridge across the Monongahela. On May 13, 1833, he was overruled and ordered to rebuild the bridge at its current location. For the wooden bridges in his section, he adopted “the plan of superstructure patented by Col. Long, of the corps of United States Engineers, denominated Jackson Bridges. Several of that denomination have been raised, and will soon be completed. All experienced workmen, who have had an opportunity of seeing them, express their entire satisfaction of the principle, and view it as a valuable system of bridge architecture.” At Will’s Creek, he urged a wooden bridge but was forced, by terms of a legislative act by Maryland, to take over the maintenance of the road and build a major masonry bridge. At Dunlap’s Creek, he could have built another wooden bridge but chose to build a first-of-its-kind, in the United States, cast iron arch bridge with a span of 80 feet and a rise of 8 feet. No record of conversations between the Chief of Engineers and Delafield exists, but it is hard to believe that Delafield did not have a hard sell on his proposal, especially since the bridge would take up almost 15% of his total budget.

On September 30, 1833, he wrote, “In the estimates of services of the year I have asked for an appropriation for a cast-iron bridge for Dunlap’s Creek, induced so to do from the circumstances of finding no durable stone that will resist the thrust of the arch required to span the creek…preferring it to a wooden structure perishable from the decay of timber, and exposed to fire…”

Even with a much higher first cost, he convinced the Chief of Engineer, Gen. Charles Gratiot, that it was a good investment. Brownsville was home to several iron works and was not far from deposits of iron ore. He purchased pig iron from a mill in Portsmouth, Ohio, and had the iron cast in Brownsville at the Herbertson Foundry. Delafield, although a graduate of West Point, had little prior experience in iron bridge building and was even feeling his way in the design and construction of wood and masonry bridges.

He wrote on March 31, 1836, of his design,

“In some one of my communications of last fall, I intimated that I had matured in my mind the plan of the Cast Iron Bridge to be constructed over Dunlap’s Creek – differing in its principles of construction from any of which I could find a notice by either English or French Engineers…Presuming you would be pleased to see the plans before I can have them in my power to file copies of them in your Department, and that the Secretary of War might wish to see the plans of the first iron bridge to be constructed in the country, I have directed Lt. McKee to pass through Washington, on his way to Brownsville.”

The wrought iron was forged in John Snowdon’s Vulcan Iron and Machine Works, also in Brownsville. Attached to his 1837 Annual Report was a memoir on the bridge entitled, Memoir on the Dunlap’s Creek Bridge on the Cumberland Road East of the Ohio, and two drawings of the bridge. It was signed on September 27, 1837, by both Delafield and Lt. George W. Cass.

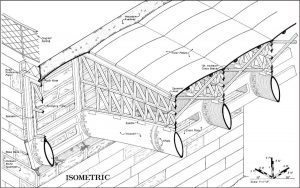

View showing tubular sections and cast iron latticing. Steel work in the right, foreground supports sidewalks added in 1920.

His design consisted of five rows of elliptical tubular castings, spaced 5.77 feet on center, bearing on spring plates embedded in the masonry. Each tube consisted of 9 castings (called voussoirs after masonry practice) cast with flanges with holes to bolt the sections together. They were built on wooden falsework set in the creek bottom. Why Delafield adopted an elliptical shape rather than a more common circular shape is not clear. His outer ellipse had a major (vertical) axis 2 feet 6 inches in length and a minor (horizontal) axis 10¾ inches in length. All 45 tube sections were identical and had a wall thickness of 1.37 inches. A total of 250 castings were required for the entire bridge. He wrote, “the voussoirs composing the same rib are not in immediate contact; …to prevent lateral motion, cross plates traverse at right angles all the ribs, and are as many in number as there are joints between the voussoirs of each rib. The cross plates are 24 feet 7 inches from out to out, 2 feet 6 inches wide and 2½ inches thick.” They were not solid, as a rectangular cutout 4 feet 10 inches wide and about 12 inches high was placed between each voussoir to cut down on the weight. Even with the cutouts, the cross pieces weighed almost 2½ tons.

Between the voussoirs and the deck, he noted, “…supporters are composed of open ribs resting vertically on the hollow elliptical ribs and present the figures of triangles (two rows above the other).” On these supports, he had curved cast iron floor plates one inch thick, bolted together to support the 1-foot 6-inch thick McAdam metal paving that was kept in place laterally by 1-foot 6-inch “road covering plates” along the edges of the bridge. X braces (St. Andrew’s crosses) were placed between each row of tubes for lateral bracing, supplementing the large cross plates.

The abutments were huge, being 25 feet across the front, 42 feet high, and 14 feet thick in addition to long wingwalls on the Brownsville side of the bridge. The masonry alone amounted to one-half the cost of the entire bridge.

Since this was to be a first of its kind, Delafield knew that no contractor would submit a fixed price for the iron superstructure fabrication and construction, and chose to build it on a kind of “Cost Plus” basis, writing,

“I propose having the castings made by a foundry at Brownsville, purchasing all of the material myself, paying the mechanics and laborers for the time actually employed, and as a rent for the foundry, use of the lathes, engines, workshops, tools, and skill and service of the Proprietor and foreman, give a percentage upon the wages of the people employed by this course. I secure a choice of metal and can control the mode of casting in any way it may be found desirable.”

Delafield and his colleagues had many difficulties in building the bridge and keeping the cost within budget. One of Delafield’s assistants, Lt. Cass, stated, “Everything seems to have gone wrong since commencement of this work and I do hope that I may never have such another job in my life. It has from the beginning to this time given me more trouble and uneasiness than a work of 10 times the magnitude ought to have done…”

Delafield’s 1835 – 1837 annual reports note several difficulties:

- September 1835 – Difficulties obtaining rights-of-way delayed the start of the project.

- September 1836 – Unprecedented wet weather, high water in the river, and great scarcity of mechanics prevented completion by this date. However, the southwestern abutment was completed and the northwestern abutment had been built three feet high.

- Half of the 140 tons of pig iron had been delivered to the foundry by the fall of 1836. Patterns for the casting of the bridge were complete and castings were proceeding rapidly.

- Increased prices for pig iron over original estimates ($35 versus $55 per ton) increased costs. “A long and protracted correspondence grew out of the location of this bridge, by the refusal of the authorities of the town of Bridgeport to permit it being located on the site selected by the engineer as best suited for the public interest.”

- November 1837 – The masonry of the Dunlap’s creek bridge was finished in September 1837. The cast-iron for the arch of the bridge was not finished. The five center sections of the elliptical cylinders (voussoirs) and two flooring plates remained to be cast. A few pieces of castings (St. Andrew’s crosses, and road-sustaining plates) remained to be fitted together. The wrought-iron railing remained to be made.

- By late 1837, it was necessary for Delafield to request an increase in appropriations again. He noted all of the issues outlined in the report and expounded on the “novelty of the undertaking.”

Some traffic started to cross the bridge in 1838, but it was not completed with railings until 1839. Its grand opening was on July 4. The railings and finish work had to be scaled back due to funding problems.

The bridge came in well above Delafield’s original estimate, eventually costing just under $40,000. A masonry bridge would have cost, if the stone was locally available, about $24,000 and a wooden bridge only about $7,000. The high cost of cast iron and the problem of fitting the faces of the cast iron for the bridge resulted in very few bridges of this type being built. This was especially true since the cast and wrought iron trusses, starting with Squire Whipple’s bridges, became very cheap to build. The bridge, however, has served travelers for over 178 years and recent inspections have shown the iron is still in excellent condition.

Similar bridges were General Montgomery Meigs’ Pipe Aqueduct Bridge in Washington, D.C., built in 1860, and Wendel Bollman’s Pipe Bridge in Baltimore in 1877. Both of these bridges used circular pipes which are the most efficient shapes to carry compressive loads, l/r, equal in all directions, and to conduct water at the lowest wetted perimeter per unit of cross sectional area.

The Dunlap’s Creek Bridge is on the National Register of Historic Places (1978) and is also a National Historic Civil Engineering Landmark (1978). Sherman Day wrote in his 1842 book, Historical Collections of the State of Pennsylvania, “It is the only one of its kind and probably the most splendid piece of bridge architecture in the United States.”

Delafield went on to a noteworthy career, becoming Superintendent of West Point and Chief of Engineers for the United States Army.▪