The Wharf development is transforming Washington DC’s storied Southwest quadrant by creating a mile-long waterfront neighborhood that includes retail, residential, hospitality, offices and cultural complexes as well as a public park and piers. 525 Water is a 107-unit condominium building in Washington, D.C. and the first residential project to be constructed in The Wharf. The 525 Water project is located in the lower right area of the development shown in Figure 1. Featuring views of the Potomac River and fronting a new 3.5-acre Waterfront Park (Figure 2), these new condominiums extend five stories above grade and contain over 105,000 square feet. The building is primarily a square shape, with a curved southern exposure matching the radius of the streetscape (Figure 3). Its courtyard offers landscaped scenery and natural lighting for residents of the interior units. Other amenities include a club room, private rooftop, balconies, green roof, and a two-story garage substructure. Final punch list items were completed in July 2016 with a construction cost of $30 M.

The project consisted primarily of load-bearing cold-formed steel framing (Figure 4). The load-bearing wall panels support concrete over Hambro joists for levels three and above. Over 9,000 linear feet of wall framing containing complex curves and angles was prefabricated off-site by FrameCo, Inc. On May 5, 2015, the first of over 1,040 panels was placed on the second floor. In just three months, the structure was topped out with its final pour at the roof. Although masonry elevator and stair shafts were included in the building design, cold-formed X-braces stabilize the building above the second level. The garage and first-level structure were constructed with concrete columns supporting reinforced two-way concrete slabs. The first story exterior wall is infill curtain wall fabricated with cold-formed steel framing and deflection track at the top of the wall. These curtain walls were installed after much of the second story was already in place.

The exterior facade is composed primarily of brick, metal panels, and glass. In some locations, the cold-formed steel framing was required to support the vertical as well as the lateral loads imposed by the brick veneer. A prominent feature of the exterior is the tower occurring at the building’s southwest corner, (Figure 2) which contains floor-to-ceiling glazing supported by miscellaneous cold-formed shapes and structural steel.

The benefit of cold-formed prefabricated panels on this project is best exemplified by the beam pockets that were required to achieve a positive load path (Figure 5). With over 100 steel beams at the fifth level, Excel Engineering, Inc coordinated beam depth, width, and bearing locations so that appropriately sized cold-formed posts could be provided. The posts were capable of supporting each beam while still allowing adequate space for the field crew to make their connections. This avoided costly delays associated with traditional ironwork. Adding to the complexity, more than 550 MEP (mechanical, electrical and plumbing services) sleeves penetrated each level. Excel coordinated every stud location to avoid interference and enable a much faster installation of the wall panels.

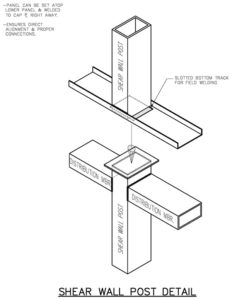

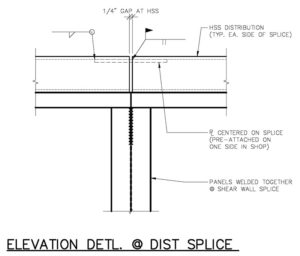

Shear walls are an integral part of many projects, and this project was no different. Aligning the shear wall posts floor-to-floor, in particular through concrete, is difficult and required Excel to work with FrameCo on a creative solution. Taller cold-formed shear wall posts with cap plates were designed and supplied within each panel (Figure 6). The panel above contained slots in its bottom track at these posts, enabling the field crew to properly align the shear wall post and directly weld each assembly together. Due to the nature of the project, some shear walls were not able to be shipped full-length. Therefore, Excel created an overlap detail (Figure 7) to maintain continuity across the splice between shear wall panels. This involved welding a plate that extended past the end of one panel so it could be fastened to the adjacent panel once set in the field.

Due to an aggressive construction schedule, Excel Engineering, Inc. developed an innovative process to communicate new information among team members quickly. Requests for Information (RFIs) were submitted well before the engineering was completed, and a level of importance was assigned to each request so the design team could address time-sensitive issues first.

Excel also provided a level of accelerated service by handling complex aspects directly with the project design team. This coordination process alerted the design team of potential issues, allowing them to be resolved before they could create delays. For instance, in-depth coordination with the stair fabricator was required for beam design at the fifth-level stair openings. By anticipating the need and addressing it upfront, Excel was able to produce accurate wall panel elevation drawings quickly.

Combining attention to detail with innovative design, Excel and FrameCo demonstrated that prefabricated cold-formed steel systems can work perfectly as the primary structure for any mid-rise building. 525 Water was recently recognized by the Cold-Formed Steel Engineers Institute with a 2016 CFSEI Design Excellence Award for its’ innovative use of cold-formed steel.▪

Project Team

Owner: RWP, LLC

Engineer of Record for Structural Work: Ehlert Bryan

Architect of Record: SK&I Architectural Design Group, LLC

Cold-Formed Steel Specialty Engineer: Excel Engineering, Inc.

Cold-Formed Steel Specialty Contractor: FrameCo, Inc.

General Contractor: Balfour Beatty Construction