First Railroad Bridge across the Connecticut River in Massachusetts

The Boston and Worcester Railroad, one of the first railroads built in Massachusetts, was chartered in 1831 and opened to Worcester in 1835. This was followed by the Western Railroad, which would begin in Worcester and run to the New York State line, connecting with the Hudson and Berkshire line that ran to Albany, New York, on the Hudson River. The latter line was completed in 1838. The Western Railroad reached the easterly shore of the Connecticut River at Springfield on October 1, 1839. The line of the Western Railroad from W. Springfield to the New York State over the lower Berkshire Mountains was completed on May 4, 1841. To make the connection across the Connecticut River required a long bridge. Up to this time, most wooden bridges were constructed to the design of Stephen H. Long and by Ethiel Town. On the western segment, many bridges were short stone arches. Other early wooden railroad bridges were by Lewis Wernwag over the Monocacy River and Harper’s Ferry over the Potomac River for the B & O Railroad (STRUCTURE, August 2014). Burr’s Trenton Bridge (STRUCTURE, June 2014) across the Delaware was retrofitted for railroad service in 1835 and Moncure Robinson built several long Town Lattice Trusses for the Philadelphia & Reading Railroad as well as the Richmond & Petersburg Railroad in Virginia. (STRUCTURE, October 2014)

The engineers for the Connecticut River crossing were William Gibbs McNeil, George Washington Whistler and William H. Swift, who were all early graduates of the United States Military Academy at West Point. They were planning on using Long Trusses by Stephen H. Long for the bridge until William Howe came to them with a new plan that he claimed was superior to the Long Truss.

Howe was a millwright from Spencer, Massachusetts, located about 8 miles west of Worcester and on the line of the railroad. He was one of the three inventive Howe bothers. His brother Elias invented the sewing machine and brother Tyler the spring bed.

Howe designed many churches and meeting houses, some of which required long truss spans for the roof. They were all entirely of wood with the exception of some iron bolts. Long’s truss was also entirely of wood. At an old church in Brookfield, he saw a truss of wood that was sagging and there was no way of adjusting the sag. He got the idea of replacing the vertical wooden tension members with wrought iron rods that were threaded on both ends, which made it possible to adjust any sag in the truss. This was fully intuitive, as Squire Whipple had not then published nor even developed the method of analytical truss design. It is likely he tried this out on a roof for a church in Warren. He then convinced Swift and Whistler to try his design on a short 70-foot span across the Quaboad River at Warren, just west of Spencer. It was successful, and they gave Howe the contract to build a much longer bridge at Springfield.

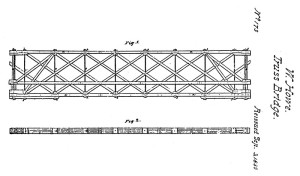

Howe received a patent, #1,711, on a bridge on August 3, 1840 while he was building the Connecticut River Bridge. It had braces and counter braces crossing two panels, with additional braces at the ends and additional longitudinal member just below mid height. Long claimed that it was a violation of his patent rights, but was unsuccessful in convincing the Patent Office they had erred in granting the patent to Howe. Howe wrote, “The truss-frame which I am about to describe is in many respects similar to the truss-frame for which, under several modifications thereof, Letters Patent of the United States are about to be granted to me, under an application therefor dated the eleventh day of May, 1840; but it differs therefrom in the effecting of the straining up, and cambering, by the operation of iron bars, or rods, furnished with screw nuts, and of wedge pieces so placed as to be rendered effective by the action of said screw rods, or bolts.” He claimed in his patent “The manner in which I have combined the iron bolts, and the wedge pieces against which the braces and counter braces abut, so as to cooperate in increasing the camber to any desired extent, the whole truss-frame being constructed and acting, substantially as herein set forth.”

There is no record of a patent issued on May 11, 1840, but there is one, #1,685, dated July 10, 1840 for a much more complex truss with a supporting arch and no iron rods that he claimed could be adjusted by wedges, etc. On both patents, he gives his address as Warren, Massachusetts.

A wooden carriage and wagon toll bridge had existed nearby, since 1805, with a length of 1,234 feet and a width of 30 feet. Howe’s design was for seven spans of 180 feet, for a total length of 1,260 feet with masonry piers.

Unlike many old bridges where information is lacking, a complete description of Howe’s Bridge was published in The Journal of the Franklin Institute in May 1842 by Lewis M. Prevost, Jr., C. E. He wrote in part,

Each truss is formed of a system of main braces, A, A, A, seven inches square, of white pine, inclined from the piers towards the centre of the span, abutting upon white oak shoulders, C, C, C, which are let into the chords D, D, to a depth of two inches; and counter braces B, B, B, of the same dimensions, inclined in the contrary direction, passing between each pair of main braces and also abutting upon the white oak shoulders. The upper and lower chords are composed of planks forming, in all, six horizontal beams of seven by ten inches each. The whole truss is firmly bound together by the iron rods E, E, E, two inches in diameter, passing between the main and counter braces, and through the white oak shoulders; having screws cut on their lower ends, and the lengths adjusted by means of burrs; these suspending rods act in lieu of the king and queen posts usually employed, and sustain the lower chords, on which the girders, F, repose. The spans are 180 feet each, and the deflection of the bridge in the middle of a span, during the passage of a locomotive and train, by careful measurement, was found to be only a quarter of an inch.

Some of the principal advantages of this plan are that the stress comes upon the end grain of the main and counter braces, and is in the direction of their length – consequently there is not the same danger of the settling which occurs in lattice bridges, in consequence of the crushing of the pins and the splitting of the lattices at the ends and there being a free circulation of air between the main and counter braces, the bridge is not so liable to the speedy decay which occurs in lattice bridges, wherever the lattices come in contact. There is also less timber required in Howe’s truss than in Town’s.

For a bridge of 180 feet span, there are in Howe’s truss frames, 28,636 feet board measure.

For a bridge of 180 feet span, there are in Town’s double lattice, 46,080 feet board measure.

These quantities of timber have been calculated for the trusses, or sustaining parts only, of the two plans respectively; supposing each to span 180 feet, and the truss depth of the former to be eighteen feet, whilst that of the latter was assumed at nineteen feet eight inches, both measured from the top of the upper to the bottom of the lower chord: the roof and floor would of course contain the same quantity of timber in both cases, and has therefore not been included, being evidently unnecessary in a mere comparative estimate of the amount of lumber in each; we must, however, observe that the above described trusses upon Howe’s plan, contain the subjoined quantity of iron, – a material not used in the lattice bridges – viz: Approximate weight of iron in the suspending rods and burrs of the two trusses of one of Howe’s bridges, of 180 feet span, 21,100 pounds. Approximate weight of iron in the transverse top ties, 710 pounds. Total, 21,810 or nearly, nine and three-quarter tons of wrought iron.

The usual cost of the superstructure of covered railroad bridges, upon the plan above described, with long spans, and for a single-track railway, inclusive of all materials, and of the workmanship, is about $22 per lineal foot of floor.

In conclusion, the writer will add his conviction, that in bridges with spans equal to, or exceeding, those of the bridge at Springfield, the peculiar truss above described, will be found superior in strength, stiffness, and durability, to those of Town’s double lattice plan.

He added struts from the piers up to the first, second and third panel points, with an extra 9- by 12-inch bolster. His panel length was only 7 feet and, with a height of truss of 18 feet, was a little flatter than the preferred 45°. He had wrought iron bars across the tops of the trusses for lateral stiffness. At the ends of his braces and counterbraces he had wooden shoes, white oak shoulders, to transfer the diagonals loading to the top and bottom chords. His braces and 2-inch wrought iron bars were all the same size over the length of the truss as were the chords, so it is obvious he did not fully understand the loading in the members. The trusses were continuous over the piers in the same way many Long Trusses had been and as the earlier Burr, Palmer and Wernwag bridges were. The bridge opened in October 1841, completing the line linking Boston with the West at the Hudson River. The trusses were covered, not roofed and painted with a whitewash; a layer of tin was placed on the flooring and painted black. The tin was to cut down on the possibility of fire. The bridge was replaced in 1855.

With the opening of the Springfield Bridge, the Howe Truss became the bridge truss of choice, given its stiffness, adjustability and lower cost, for many railroads around the country. Whistler left the Western Railroad and went to Russia to build the Nikolayev Railroad in 1842, and built many Howe Trusses on that line as well. Howe’s bridge became known around the world, as technical journals of the time spread the word about advantages of the style. Many were covered and roofed but some were not, and those generally had a life of 15 years or less. The Foxburg, Pennsylvania Bridge for the B&O Railroad over the Allegheny River was double decked and survived until 1921, when a steel bridge replaced it. Most Howe Trusses after the Springfield Bridge were not double intersection and had cast iron shoulders (shoes) to receive the braces rather than wooden ones. On August 28, 1846, he obtained another patent, #4,726, adding an arch to his truss pattern. Many Howe Truss bridges still exist and carry roadways and light duty railroad traffic.

What Howe had done was to introduce wrought iron rods for his vertical tension members, enabling bridge owners to keep the camber in their bridges. Squire Whipple, in his 1847 Treatise on Bridge Engineering, gave the engineering profession the ability to design each member of a truss to carry the load it would see in service; this made it possible to vary the size of its members as necessary along the length of the truss. Howe’s brother-in-law, Amasa Stone, built many Howe trusses in the mid-west. On the 150-foot long Ashtabula Bridge, he replaced the top chord wooden members with wrought iron I-beams and the lower chord with wrought iron rods making it an all iron bridge. Unfortunately, the bridge collapsed on December 29, 1876 killing 90 people. In iron, the Pratt Truss over time generally replaced the Howe Truss for both railroad and highway traffic. Howe, however, was able to retire and live off the patent fees he charged for use of his patented truss.▪

This is the last in the series of notable wooden bridges. In the next and following issues, Dr. Griggs will discuss the cast and wrought iron bridges that were dominant between the 1840s and 1880s.