The Statue of Liberty National Monument reopened to visitors July 4, 2013 after a 20-month renovation to upgrade visitor access, egress, safety, and comfort.

Structural improvements included installation of new primary and emergency elevators and two independent, fire-rated, and code-compliant stairs within the pedestal. The improvements include new egress routes that extend through the War of 1812-era Fort Wood surrounding the monument.

Working under the auspices of the National Park Service, as part of a multi-disciplinary design team led by Mills + Schnoering Architects, Keast & Hood Co. provided comprehensive structural engineering design and construction administration services. The team used Building Information Modeling (BIM) software, regular in-person and online meetings, and a commitment to creative problem-solving to ensure the renovation went smoothly.

Weaving new structural elements through a 10-story, 27-square-foot shaft punctuated by obstructions presented unique structural engineering challenges. The 126-year-old monument’s location on an island accessible only by barge intensified the task.

Statue Structure

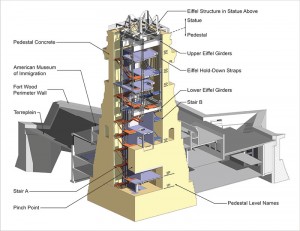

A gift from the people of France, the Statue of Liberty National Monument was constructed in 1886 and consists of a 151-foot tall statue atop a 127-foot tall pedestal. French sculptor Frederic Auguste Bartholi designed the statue; Gustave Eiffel, designer of the Eiffel Tower, designed its supporting structure. American architect Richard Morris Hunt designed the granite-clad, cast-in-place concrete pedestal.

The monument sits in the center of the former Fort Wood on Liberty Island in New York Harbor. The infilled plaza, known as the terreplein, lies between the perimeter fort walls and the monument pedestal.

The Statue of Liberty must withstand both gravity and lateral loads. The Eiffel structure within the statue contains four primary vertical pylons, the centroid of which is eccentric to the pedestal below.

At the top of the pedestal, two pairs of girders cross in the shaft. These girders transfer gravity loads to the pedestal concrete and transfer uplift loads to a series of large tension straps that extend down to a second set of Eiffel girders located near pedestal mid-height. The lower girders are embedded into the walls of the pedestal at a point where there is enough concrete dead load above to resist the large overturning forces that result from wind acting on the statue. Each Eiffel girder is a series of four built-up I-sections laced together with plates riveted to the top and bottom flanges.

Pedestal levels are named 1P (ground level) through 7P (top level). Level 3P falls slightly above the terreplein. Above 3P, the interior shaft measures 27 feet square, and the wall thickness varies from six to 18 feet to support the granite cladding. Below 3P, the pedestal steps outward. Earlier renovations widened the center shaft below 3P from 10-feet square to 27-feet square on 1P and approximately 15-feet square between 2P and 3P. This narrow location is known as the “pinch point.”

The statue contains a double-helix stair that extends from the top of the pedestal to the crown. Prior to this project, access to and egress from the base of the statue was via two open stairways that hugged the outside walls of the pedestal’s central vertical shaft.

Enclosed stair structure passing through Eiffel girders between levels 3P and 4P. Courtesy of Brian Rose.

Design Challenge

The fundamental design challenge was determining how to fit an elevator and two, code-compliant egress stairs within the narrow shaft of the pedestal.

Following removal of the old stairs and two elevators, two primary physical constraints influenced the new layout: the pinch point of pedestal concrete between levels 2P and 3P, and the Eiffel girders at pedestal mid-height. When these two constraints were overlaid in plan, only two locations could accommodate the main elevator through the full height of the pedestal: at the center or along the west wall.

The west elevator location was chosen because it enables both new stairs to rise through the center opening of the Eiffel girders, creating a more interesting interpretive experience for visitors.

For most of the pedestal height, one stair is located on the shaft’s north side and the other is located on the south side. Intermediate floor levels and the existing pedestal walls support the new stairs. The floor structure consists of concrete slabs on steel deck supported by structural steel framing. The stair stringers employ rectangular hollow structural sections. New beams connect to the existing pedestal walls with post-installed anchors. One stair exits the pedestal at 3P while the other extends down through the pinch point to 1P.

Between 3P and 4P, both stairs pass through the center of the Eiffel girders. To maintain fire separation, a fire-rated glass enclosure supported on the stringers envelopes one stair. There were extremely tight tolerances between the new stairs and the Eiffel girders, which the new structures were not permitted to touch.

Determining the elevator support structure presented another significant design challenge. Several options were considered, including shaft wall on structural steel framing, concrete unit masonry, precast, and cast-in-place concrete. Ultimately, cast-in-place concrete was chosen because it could be sculpted to suit the tight clearances and existing spatial irregularities, and because it was aesthetically consistent with the historic fabric surrounding it. A self-consolidating, 4000 psi concrete was used to cast 7.5-inch thick architectural concrete walls. Concrete arrived on site in ready-mix trucks that traveled by barge to the island

Collaboration with BIM

Design success hinged on effective systems integration. The collaborative design process and use of BIM software proved essential. In 2009 when design commenced, most firms involved in the project were fairly early in the BIM adoption period but chose to use BIM because of the project’s geometric complexity.

Led by Mills + Schnoering Architects, each design consultant produced a BIM model. Teammates participated in regular meetings and web conferences, shared their models, and resolved conflicts to coordinate all designs. Although the contract documents consisted of traditional drawings and specifications, BIM easily enabled the presentation of both two-dimensional and three-dimensional views on the drawings to aid visualization by the contractors. The construction phase proceeded with very few requests for information (RFIs) related to design intent or inter-disciplinary coordination issues, proving the benefit of the BIM approach.

Surprises in the Field

Discovery of unexpected field conditions drove a high level of structural involvement during construction. The most significant of these discoveries arose quite early. After removal of the old stairs and elevator, the contractor demolished some of the mass concrete foundation at 1P to create the new elevator pit.

Logistical and operational considerations precluded pre-construction materials testing within the pedestal. However, participants in the 1984-85 renovation recalled the pedestal concrete as extremely hard and difficult to penetrate. Given the expectation of relatively high-strength existing concrete, the new elevator shaft walls were designed to bear directly on the base slab at 1P. The elevator pit was expected to require laborious demolition of the mass concrete foundation. Unfortunately, after breaking through a thin concrete wearing slab, workers could easily remove the remaining concrete with hand tools. This unexpected finding triggered a detailed investigation and testing; the result was that, although quite deep and uniform, the concrete at 1P was also quite lean with an average strength of 1,200 psi. Consequently, the elevator shaft base was redesigned as a mat foundation to gently distribute the load of the new shaft walls over the existing lean concrete.

The unexpectedly low concrete strength raised questions about existing material strength and suitability of the new connections to the historic concrete throughout the monument. Tests expanded to all pedestal levels in two phases: core sampling and compression testing to determine the approximate compressive strength of the existing material, and pull testing of anchors proposed for new steel connections.

Compression test results showed a puzzling variety of strength results ranging from 700-9,500 psi, and noticeable differences in material strengths above and below 3P.

The answer to this mystery lay in the history of construction and subsequent alterations of the monument. At 3P – the pedestal’s original entry point – the interior of the pedestal starts to open up and become wider and the exterior walls become thinner. Historic photos show visitors ascending an exterior staircase from the terreplein to 3P. On the interior, the narrow pinch point presents at 3P. Records showed the original shaft as a constant ten feet square from 3P down to the base at 1P. The original concrete above 3P was, as rumored, quite hard with an average strength of 4,500 psi, whereas below 3P, the average strength of the original concrete was a mere 1,500.

It became clear that the original designers saw the construction below 3P as a mass concrete foundation wherein a much lower strength could be justified. Above 3P, the walls of the pedestal thin considerably but employ a higher-strength material. Understanding this original design approach proved the range of concrete strengths made perfect sense. Once confident in where and why material strength differed, the structural team adjusted post-installed connection details to suit varying concrete strengths at different locations within the monument.

Another discovery revealed undocumented vertical chases that once hid electrical raceways. Thin concrete covered the raceways to match surrounding solid concrete, making them impossible to discern visually. Ground penetrating radar helped identify locations. After documenting the chases, engineers redesigned affected steel connections to avoid connecting a new floor beam or stringer to a concealed chase.

National Pride

Given the geometric and logistical complexity of the project, success could easily have been elusive. However, a committed team of designers and contractors used the coordination efficiencies of BIM and a shared sense of purpose and national pride to effect a successful outcome. Every team member involved in the Statue of Liberty renovation considered it an honor to preserve and improve the landmark, and ensure its continued safety and accessibility for generations of visitors.▪

Project Team

Owner: National Park Service

Structural Engineer: Keast & Hood Co., Philadelphia, PA

Architect: Mills + Schnoering Architects, LLC, Princeton, NJ

Mechanical Engineer: Joseph R. Loring & Associates, Princeton, NJ

Construction Manager: Atkins Global Consulting Engineering, New York, NY

General Contractor: Joseph A. Natoli Construction Company, Pine Brook, NJ

Steel Subcontractor: Weir Welding, Carlstadt, NJ

Concrete Subcontractor: Macedos Construction, Flemington, NJ