Transforming a 21<sup>st</sup> Century Urban College Campus New York, NY

The CUNY John Jay College School of Criminal Justice Expansion Project is a new 625,000-square foot academic building in Midtown Manhattan. The facility consists of a 15-story tower on 11th Avenue and a four-story podium with a garden roof that connects to the College’s existing Haaren Hall on 10th Avenue. Following significant growth in criminal justice interest over the last decade (partially in response to the attacks of September 11th) the new building was planned to accomplish a doubling of the existing facilities and unification of the campus into one city block – creating an academic city within a city.

The 65,000-square-foot podium garden roof, known as ‘Jay Walk’ by the students, links the College’s existing Haaren Hall to the new tower on 11th Avenue and provides an oasis from the city below. Courtesy of SOM.

In explaining the design concept, Abadan Mustafa of SOM said, “Criminal justice is not something that should be hidden away. Glass makes the relationship to inside and outside clearer. It relates to our ideals of transparency and justice, the way justice is applied to everyone equally and openly.” The new facilities offer traditional college campus amenities including classrooms, offices, research laboratories, theaters, lounges, and flexible collaboration spaces. In addition, unique features specific for future investigators and law enforcement officers include a ballistics room, areas for chemical storage and analysis, mock trials, and an emergency control center simulation lab.

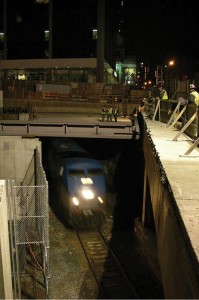

Construction over the tunnel was done at night and coordinated around the train schedule. Noise and vibration were controlled by isolating the tunnel enclosure from the tower structure.

Site Challenges

In response to a shallow Amtrak tunnel that cuts through a corner of the site, the John Jay structural system is distinguished by a grid of rooftop trusses which hang the perimeter of eight floors below. This creates a dramatic column-free cafeteria space on the 5th floor, with views of the Hudson River for the full 195-foot width of the building.

Two layers of structure were provided to effectively isolate the building from the train vibration and noise. The main building structure spanned over and behind the train tunnel, which was enclosed with a hollow core precast plank ceiling and concrete crash walls.

At points of convergence, creative detailing was required to maintain the load path and necessary separation.

Another challenge was accommodating the almost two-story change in grade between 10th and 11th Avenue. A second main entrance to the building occurs along 59th Street and negotiates this steep slope. To design for this condition, the perimeter columns – in an area that support heavy loads from the rooftop garden – were eliminated, and the entrance was pulled back to allow room for the necessary steps and ramps. Story-deep trusses were fit inside the walls of the 4th floor classrooms to efficiently accomplish the 40-foot cantilever out to the tip of a V-shaped tapering canopy.

The interior architecture also responded to the sloped grade with a series of cascading staircases and escalators that complicated the structure, but allowed for fluid circulation to all parts of the campus. “The cascade replicates a miniature Manhattan, with the ‘travelers’ passing through different building functions and academic departments rather like the squares – Madison, Herald, and Times, among others – that bisect Broadway and function as independent nodes within the city,” Mustafa said. A large skylight supported by architecturally-exposed narrow tube sections provides natural light into these main circulation areas and offers views into the space from the garden roof.

Main entrance on 11th Avenue. Setbacks in the façade were an important aesthetic feature that also reduced the impact of the load on the shallow train tunnel below.

Hanging System

Accommodating the necessary two layers of structure around the train tunnel mandated a practical limit to the weight that could be supported. After exploring numerous options, the hanging solution was favored by SOM and DASNY and adopted for numerous reasons, including assistance in achieving the series of distinguishing setbacks that frame the west façade’s main entrance along 11th Avenue. The hanging system was continued around the full perimeter to balance the weight, complete the column-free aesthetic, and take advantage of the thin plate hangers which could fit inside a standard partition wall instead of traditional column enclosures. To maintain efficiency, the hanging system was stopped where the structure over the tunnel could accommodate conventionally-framed floor weight. In coordination with the architect, the 5th floor was chosen for this transition, allowing the transparent column-free floor to align with the podium roof garden.

The primary construction challenge involved achieving approximately level floors when the building opened, and a 2-inch stack joint in the curtain wall at the transition floor between the conventionally framed and hung structure. To simplify the steel frame erection, the design accounted for temporary columns at the 5th floor around the tower perimeter and temporary angles bolted to the plate hangers above the 6th floor, to stiffen these elements during erection. This allowed the construction process to proceed similar to conventional construction, and maintain the project schedule. Once the truss assembly was finished, jacks at the temporary columns slowly lowered the building and engaged the trusses. At this point, the temporary columns and angles could be removed and concreting of the tower could begin.

With the temporary columns removed, the load path for the hanging structure is clear. The column-free fifth floor cafeteria offers great views of the Hudson River to the west.

Calculating the required amount of vertical cambering for the perimeter steelwork in order to super-elevate each of the 26 hanger/column locations for the anticipated deflection during construction proved to be a challenge as well. Design estimates were based on the assumed construction schedule, estimated construction loads, and realistic modeling of the structural behavior. During construction, continuous surveying verified whether the perimeter was behaving as anticipated. Once shop drawings were available for the nonstructural elements, and there was a better understanding of the schedule, a full reanalysis was done incorporating what was being learned from the surveying. This reanalysis revealed that it was likely the perimeter would not come down as much as originally thought (one reason for this being the curtain wall was actually 30% lighter than assumed in design) and field adjustments were made to lower the steel frame prior to starting the truss erection. Based on the last survey data received, this adjustment proved effective as the perimeter settling and final stack joint were tracking closely with the predicted behavior and targeted final thickness.

Future Expansion

While considered and subsequently ruled out during design, the College revisited the idea of future expansion during construction and decided this flexibility was important. The design team was asked to consider a design that allowed for an additional ten floors over the podium to raise this section to match the height of the new tower. At the time the decision was made, the podium structural steel was already mostly fabricated and the caisson foundations were actively being drilled in some of the affected areas.

After quick discussions focused on limiting the financial, schedule, and design changes, the College chose to reinforce only the below grade areas and take advantage of a hanging structural system similar to the one used in the tower to limit the affected area to the interior core. Additional elevator pits with knock-out slabs were provided along with significantly reinforced foundations based on the anticipated future circulation and structural weight needs. Instead of increasing the column and vertical bracing member sizes for the expected future loads, the additional capacity is intended to come from a high strength composite concrete encasement, allowing the already fabricated vertical members to still be used.

Careful detailing at the train tunnel was required to isolate members supporting the precast tunnel enclosure from the main building structure.

Other Features

The 65,000-square-foot terrace atop the podium serves as a new, outdoor gathering place for students and faculty. The planted green roof is landscaped with large grassy zones, full-sized trees, and decked outdoor dining areas which the students immediately embraced and nicknamed “Jay Walk”.

To preserve the dramatic views from the large collaboration areas in the tower of the Hudson River and this garden roof, the hanger spacing was increased to nearly 50-feet at the middle of both the east and west faces for the hung tower floors. These long span conditions created a problem in the laboratories on the 6th, 7th, and 8th floors, where strict vibration criteria needed to be met. Stiffening the floor to control the expected excitations resulted in deeper and heavier members than those that could be tolerated in the ceiling package. The alternative solution, which saved both material and depth, was to separate the problematic excitation from the sensitive equipment, adding an isolation joint in the floor between the labs and the adjacent main circulation corridor.

In addition to efficient uses of material, the project specifications were written to be environmentally sensitive. The building did not officially submit to USGBC, but LEED certification requirements were pursued wherever feasible. Fly ash and silica fume were substituted for up to 30% of the cement in the concrete. The reinforcing and structural steel were also sourced from mills regionally close to NYC and produced from over 90% recycled content.

Conclusion

The John Jay College Expansion project exceeded the expectations of owner and client, giving the students and faculty a new state-of-the-art home to be proud of, along with providing the College flexibility to adapt to whatever the future holds. The project success was due primarily to the collaborative efforts and superior skill of the design and construction team – in particular SOM, Turner, Owen Steel, and Cornell & Company – who also exceeded every expectation in realizing this special structural system.▪

Project Team

Owner: Dormitory Authority of the State of New York

Client Team: City University of New YorkJohn Jay College of Criminal Justice

Design Consultants: LERA – Structural Engineers, Skidmore Owings & Merrill – Design Architect, Turner Construction – Cost Estimator & Construction Manager, Jaros Baum & Bolles – MEP Engineers, Langan Engineering – Civil/Geotechnical Consultant, Shen Milsom & Wilke – Acoustic Consultant, Scott Blackwell Page Architect–Higher Education Planning

Contractors: Owen Steel – Structural Steel Fabrication, Cornell & Company – Structural Steel Erector, Enclos Corporation – Curtain Wall Designer