Where is it Headed?

Imagine yourself inside a house that rests on a frozen, frictionless lake when a violent earthquake occurs. Apart from noticing some up-and-down vibration, how would you know the ground is shaking? The lack of a horizontal “connection” to the earth would allow the ice to shift horizontally without affecting the house. Neither you nor the house – nor even the cup of coffee on the table – would experience the earth’s horizontal shaking. This idealized scenario exemplifies the purest concept of seismic isolation, also known as base isolation – arguably the current “gold standard” of seismic protection.

Of course, the reality of seismic isolation is not quite so ideal, if only because most building sites have legal property boundaries. Even after a major earthquake they must occupy the same piece of real estate they started on. Such earthly considerations require: 1) limitations on how far a seismically-isolated structure can be allowed to move during a design-level seismic event, and 2) a mechanism to restore the structure to its original footprint.

In essence, seismic isolation allows a structure to safely “dance” with the earth, rather than fighting it. In doing so, seismic isolation represents a departure from the widely-accepted conventional seismic design approach that essentially requires a structure to damage itself (potentially severely) to protect its occupants during a major earthquake. By definition, isolating a building from seismic shaking is the most effective way to protect not only a building, but its occupants, contents, and its function. The introduction of seismic isolation to earthquake engineering in the mid-1980s consequently resonated with the structural engineering profession’s growing interest in performance-based seismic design, which started to develop in the early 1990s.

In the thirty years since seismic isolation was first applied to a building in the U.S., extensive testing and research have been accomplished on the topic and numerous earthquakes have provided evidence of its effectiveness. However, adoption of seismic isolation has been relatively slow in the U.S. An excellent article published in STRUCTURE in March 2012 by Taylor and Aiken proposed likely reasons that U.S. adoption of the technology had not kept pace with that of other earthquake-prone countries. Primary among those reasons was added cost and design complexity. This article is intended to provide a brief introduction to seismic isolation and a status update on current applications of the technology, followed by descriptions of new developments that could herald wider application in the U.S.

Roots in the Past

The idea of modern seismic isolation has its roots in vibration isolation, wherein resilient bearings are used to protect buildings from disturbances due to vibrating machinery that predictably operate in pre-identified frequency ranges. In the case of seismic isolation, however, the vibrating “machinery” is the most unpredictable vibration source in existence – the earth itself. To date, nobody can accurately predict the most important data for designing against an earthquake: when it will occur, how it will shake, and how long it will last. This lack of definitive design criteria precludes a precisely-targeted design of any seismic protection system – including seismic isolation. Rationally designing a seismic isolation system is therefore considerably more challenging than proportioning vibration isolators for motorized equipment.

Nonetheless, seismologists, working with geotechnical engineers and geologists, are capable of determining probable ranges of ground motion amplitude and predominant frequencies of seismic ground shaking for a given site. This information can be used by structural engineers as a rational basis to evaluate and design a robust seismic isolation system for a building or other structure. Evolving computational techniques afford the engineer practical ways to utilize such input to rationally project the most likely modes of dynamic behavior of an isolated building. The fact that the International Building Code (IBC) and other relevant codes require extensive project-specific “prototype” testing for each specific type of seismic isolation bearing to be used on a project bestows a level of behavioral reliability to seismic isolation not necessarily enjoyed by other systems intended to protect structures from earthquakes.

Since seismic isolation was first applied in the U.S. in the 1980s, the relatively small market for isolation bearings has not driven a proliferation of isolator types; in fact, the readily available domestic supply of isolators has consolidated into two distinct but competitive types, with much less significant participation from non-domestic manufacturers. However, these isolator types have been substantially improved since they were developed, and their engineering properties are now much better understood and applied in practice. The sizes, displacement capabilities, and load capacities of isolation bearings have increased dramatically as well.

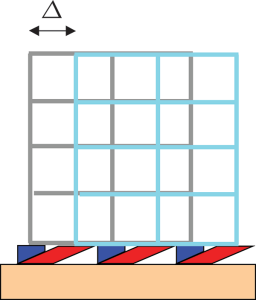

Figure 1.

How it works

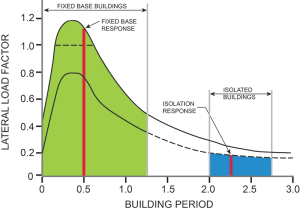

The currently applicable concept of seismic isolation works by replacing the direct, rigid connection of a structure to the earth beneath it with a set of horizontally flexible bearings that can allow the structure to remain relatively undisturbed even as the earth moves violently. A seismic isolation system may be located at the base of a building or at a story within the superstructure (Figure 1). The resulting horizontal displacement between the structure and the earth effectively lengthens the fundamental period of horizontal seismic vibration, which can significantly reduce the horizontal base shear that a structure would experience. In addition, seismic energy may be dissipated through the provision of passive damping in order to provide some control over the amount of relative displacement that may occur (Figure 2).

Figure 2.

Tools of the trade

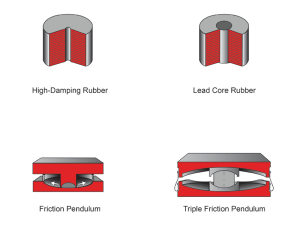

Currently available categories of seismic isolation bearings include multi-layer elastomeric devices, friction devices, and ball-bearing-based devices. Elastomeric seismic isolation bearings were originally modeled after elastomeric bridge bearings and consist of a vulcanized multi-layer “sandwich” of elastomer layers and thin steel plates. The two most prevalent types in this category are the lead-rubber bearing (LRB), which contains a cylindrical shear-yielding lead core for energy dissipation, and the high-damping rubber bearing (HDR), which dissipates energy by amending natural rubber to contain filler materials such as carbon black. In locations where linear-elasticity suffices without the inclusion of damping, the nearly linear-elastic natural rubber bearing (NRB) may be used. The most commonly used and well-known friction device is the friction pendulum (FP) isolator, which utilizes an articulated slider that moves horizontally on a spherical dish-shaped surface. The spherical shape of the sliding surface determines the translational period of the isolation system, and forces it into slight vertical movement that creates a restoring force. The most recently developed “Triple Pendulum” version of this type of device, patented and manufactured by Earthquake Protection Systems, Inc., contains a compound articulated slider with multiple sliding surfaces to allow control of the sliding sequence and the resulting hysteresis curve. Refer to Figure 3 for representative diagrams of the various isolator types named above.

Figure 3.

Current Applications

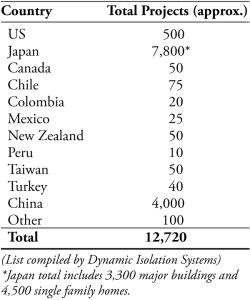

Although it is challenging to obtain accurate numbers on seismic isolation work, a recent estimate by Dynamic Isolation Systems put the approximate total of completed isolation projects at over 10,000 worldwide. This total, which is likely conservative, is heavily weighted towards Asia, particularly Japan, where vibrant “reminders” of potentially damaging seismicity occur frequently in densely populated areas. Table 1 provides a breakdown by nation. This points out a trend recognized among structural engineers who specialize in seismic isolation design: demand for the technology jumps in the years immediately following a damaging earthquake. This tendency was first noted following the 1989 Loma Prieta earthquake, and has been repeated after every subsequent major damaging event.

Table 1. Approximate numbers of seismically isolated projects worldwide – April, 2015.

Numerous types of structures are now protected by seismic isolation on highly seismic regions of the world. Examples include buildings, bridges, viaducts, pipelines, offshore platforms, telecommunications facilities, water and fuel storage tanks, power transformers, computer floors – and the list goes on. Common isolated building types include mission-critical facilities such as hospitals and emergency response communication centers, historic and/or landmark public buildings, owner-occupied office buildings, and high content-value buildings such as museums. Other less common examples include high-end apartment buildings and high-value manufacturing facilities. Still more specialized examples include a botanical storage facility containing rare/precious plant specimens, an isolated rooftop office building addition, structures with unusual architecture (Figure 4) and isolated floors (Figure 5) within buildings to support high-value contents. Not surprisingly, seismic isolation currently retains a long-held reputation as a high first-cost approach for “high end” buildings. If one ignores its potential long-term benefit, seismic isolation can seem financially out of reach for less-critical projects.

Figure 4. Courtesy of Bruce Damonte.

Figure 5.

This impression is compounded by exhaustive code-mandated evaluation, design, and review requirements that apply only to seismic isolation and other advanced seismic protective systems like passive damping. Ironically, the original developers of modern seismic isolation conceived the approach as a way to simplify seismic design, as well as to enhance predictability and performance. Special requirements in the current IBC and the American Society of Civil Engineers’ (ASCE) Seismic Evaluation and Retrofit of Existing Buildings (ASCE 41) that apply to seismic isolation but not conventional seismic systems include:

- Site-specific ground motion studies

- Design for two levels of earthquake input

- Peer review with multiple reviewers

These requirements, all of which are expensive and time-consuming, may be prudent to use for complex projects, but are generally recognized as unnecessary for simpler buildings.

In discussing cost-benefit comparison considerations between isolated and non-isolated buildings, R.L. Mayes, of Simpson Gumpertz & Heger, concludes that, considering the cost of earthquake insurance premiums, using base isolation without earthquake insurance can be a more cost-effective solution than a conventional fixed based structure with insurance when total cost of ownership is considered, despite the first cost premium for base isolation.

Positive Developments

There have been a handful of technical developments in recent years that can be expected to encourage more use of seismic isolation going forward. These developments include:

1) Recent acceptance of code revisions to simplify implementation of seismic isolation: The seismic isolation code provisions have remained largely unchanged since they were introduced as an appendix chapter to the Uniform Building Code (UBC) in 1991. In late 2014, ASCE Technical Committee 12 on Seismic Isolation & Damping under the Seismic Subcommittee of the SEI Codes & Standards Committee for ASCE/SEI 7 succeeded in obtaining approval for a number of major revisions for the 2016 edition of ASCE’s Minimum Design Loads for Buildings and Other Structures (ASCE 7) Chapter 17 requirements for the design, analysis, testing, and peer review of seismic isolation applications. These simplifications could significantly expedite the implementation of seismic isolation, as well as make it more economical.

2) New research and development: Late in 2014, researchers at Stanford University concluded a two-year long, $1.3 million NSF-funded research program to study two new types of seismic isolation bearings conceived for inexpensive application in light-frame residential construction. The validation testing for the project, called Seismically Isolated Unibody Residential Buildings for Enhanced Life-Cycle Performance, was conducted at the University of California, San Diego’s outdoor seismic shake table facility (Figures 6 and 7, page 14).The tests shook a full-scale wood frame structure, first with re-centering dish-shaped sliding isolators, then again with flat sliding isolators, both comprised of high-strength plastic on galvanized sheet steel. Stanford representatives estimate that implementing such a system might add roughly $15,000 to a house that would otherwise cost $400,000. In the author’s opinion, retrofitting an existing home with seismic isolation should be expected to be more costly.

Figure 6.

Figure 7.

3) Readily available design examples: The Structural Engineers Association of California (SEAOC) published a detailed design example for seismic isolation developed in accordance with the 2012 IBC. The example is contained in Volume 5 of the five-volume compilation comprising the 2012 IBC Structural/Seismic Design Manual, (SSDM) published in 2013. SEAOC plans to update the SSDM as the IBC is revised. The peer-reviewed example covers the use of both elastomeric and friction pendulum isolators.

4) Lower isolator prices: As the use of seismic isolation has gradually become more widespread, production of seismic isolation bearings has become more efficient, leading to gradually falling isolator prices – especially after accounting for inflation. Interestingly, the production leading to this efficiency is partly due to the proliferation in exported bearings for projects outside the U.S. A related improvement is that of production quality. One reason for this is that Japan, the largest single consumer of seismic isolation bearings by country, established a set of rigorous standards for isolator performance following the 1995 Kobe Earthquake. Japanese domestic and non-Japanese manufacturers had to improve their quality to match those standards in order to compete for Japanese business. U.S. and non-Japanese isolation customers alike have consequently experienced a spin-off benefit from the improvement. Resulting increases in, for example, elastomeric isolator shear strain capacity have allowed the use of smaller isolators for a given displacement demand, which have also helped reduce production costs.

5) Faster isolator procurement cycles: As more various sizes of isolators are produced, the number of different readily available isolator sizes has increased, reducing the need to manufacture new molds for both elastomeric bearings and ductile iron friction pendulum components. Also, isolator manufacturers have honed their testing processes, and the pre-fabrication process is now more efficient due to a growing body of empirical testing of various isolator designs, and a streamlined testing process.

6) More publicity: Various seismically isolated structures have experienced actual earthquakes. Notably, the Japanese Red Cross Hospital in Ishinomiki City in Miyagi Prefecture, located approximately 75 miles from the epicenter of the M9.0 Tohoku Earthquake of March, 2011, was open for business immediately following the event thanks to its seismic isolation system and to the function of its emergency generators. Accounts of this experience, including videos taken during and immediately after the earthquake, were described by various parties. One example is an Oregon Public Broadcasting story by Ed Jahn.

7) Development of advanced “loss estimation” techniques: A 9-year long FEMA-funded research project by the Applied Technology Council (ATC) resulted in a probability-based seismic loss estimation methodology for buildings described in a two-volume FEMA document P-58-1, Seismic Performance Assessment of Buildings, complete with free software and introduced to the profession in September 2012. FEMA P-58-1 is tailored to equip structural engineers to rationally assess and communicate seismic risk using language and concepts common to the real estate and insurance industries. The FEMA P-58-1 procedure accounts for variation in demand parameters such as acceleration and interstory drift between different seismic structural systems in assessing potential earthquake-related losses. The lower structural demands associated with seismic isolation equate to lower risk of financial losses, injury, and downtime.

8) The Green Building movement: The Green Building movement may have largely overlooked the significant greenhouse gas contribution (or savings) of structural materials, but the advantage of providing higher seismic resilience as a sustainability measure has become obvious to most structural engineers in highly seismic areas. Seismic isolation – arguably the pinnacle of seismic resilience approaches for many types of building structures – is consequently gaining recognition for its potential role in seismic sustainability.

It may be that any of the above developments do not cause an immediate boom in demand for seismic isolation. However, taken together, they should ultimately help structural engineers move the needle toward seismic isolation’s original developers’ goal of simplifying the provision of highly reliable seismic performance, as well as making it more economically attractive.▪

References

What’s Happened to Seismic Isolation of Buildings in the U.S.? Andrew Taylor, Ph.D., S.E. and Ian Aiken, Ph.D., S.E., STRUCTURE, March 2012

“Using Seismic Isolation and Energy Dissipation to Create Earthquake-Resilient Buildings”, R.L. Mayes, Simpson Gumperz & Heger, and A.G. Brown and Dario Pietra, Opus International Consultants, Ltd., Paper Number 093, 2012 NZSEE Conference www.nzsee.org.nz/db/2012/Paper093.pdf

How a hospital withstood a 9.0 quake with nary a broken window, Ed Jahn, Oregon Public Broadcasting, March 11, 2015 www.opb.org/news/series/unprepared/