Myth Versus Reality

Lightweight concrete has been a staple of the built environment for centuries, predating the Roman Empire. While some early lightweight concrete structures still stand, their materials bear little resemblance to today’s offerings. Industry professionals now recognize structural lightweight concrete as a strong, low-density mixture of Portland cement, water, and various combinations of normal weight aggregates and lightweight aggregates. In such concrete, lightweight aggregate produced from shale, clay, or slate is heated to approximately 2000 degrees F in a rotary kiln process. During this process, it softens and bubbles form that remain as unconnected pores when it cools.

Since the early 1920s, industry professionals have effectively employed structural lightweight concrete to solve weight and durability problems. Yet misconceptions about the material’s light weight and porous form and how they impact end-use performance in composite metal decks for floors and roof slabs still exist. This article reviews three relevant misconceptions to help set the record straight.

Myth #1

The water absorption of lightweight aggregate reduces the strength and durability of structural concrete.

A pervasive industry belief is that greater water absorption by aggregates reduces the performance properties of structural lightweight concrete. However, data from a study by Byard and Schindler at Auburn University (2010) indicate that the aggregate’s raw material has little bearing on performance.

The study compared the performance of structural lightweight concrete using three common mixture ratios:

- An internally cured mixture for which a fraction of the conventional fine aggregate (sand) was replaced with prewetted lightweight fine aggregate;

- A commonly used sand lightweight concrete mixture, for which lightweight coarse aggregate and conventional fine aggregate (sand) were used; and

- An all-lightweight concrete mixture that uses lightweight coarse aggregate and lightweight fine aggregate (no normal weight aggregate).

All three types of lightweight aggregate met the standard materials specifications, AASHTO M 195, Standard Specification for Lightweight Aggregates for Structural Concrete, or ASTM C330, Standard Specification for Lightweight Aggregates for Structural Concrete. As a control, these mixtures were compared to the performance of a normal weight concrete made with river gravel. (Caution: Although with the same title, AASHTO M 195 and ASTM C330 are two different specifications. Therefore, it is incumbent on designers to determine the differences.)

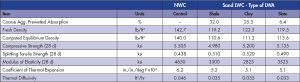

The results show that shale and clay lightweight aggregates have markedly higher absorptions than the slate lightweight aggregate (see Table). If Myth #1 were true, the mixtures using these materials should have had reduced strength and durability, but they did not.

There was no significant difference between the 28-day compressive and splitting tensile strength data for the shale and clay aggregates and the slate aggregate. Further, the splitting tensile strength for the slate aggregate was the lowest of the three mixtures. These outcomes dispel the myth that the absorption of the aggregate drives structural lightweight concrete’s strength and durability.

Myth #2

Lightweight concrete floors take much longer to dry.

Due to its internal pore network, lightweight aggregate absorbs and stores water before releasing it gradually over time, resulting in higher absorption than conventional aggregates. The aggregate is prewetted before mixing to maintain slump and allow pumping. This water needs to evaporate until the floor slab achieves equilibrium with the ambient conditions. While there is always the concern that moisture that leaves a concrete slab can bring alkalinity to the surface and negatively interact with some flooring adhesives, this concern is amplified with lightweight aggregates. The belief is that the excess water retained in the pores greatly extends the drying time, precluding it from use in buildings with fast-tracked construction timelines.

Recently, the Expanded Shale, Clay, and Slate Institute (ESCSI) sponsored a study (Craig, 2011) comparing lightweight and normal weight concrete slabs that refuted this myth. It revealed that while there was more initial water in the lightweight slabs, the drying times were similar to normal weight slabs. In fast-paced construction, it is important to note that the findings indicate that both types of concrete will likely not reach the industry-accepted limits when it is time for the installation of adhesive-attached floor coverings and will require moisture mitigation techniques.

Rewetting poses a greater obstacle to slab drying than initial water content. Until a structure is enclosed, the slab cannot begin to dry, regardless of whether it is lightweight or normal weight concrete. This makes it even more critical not to dismiss the benefits of lightweight concrete simply due to concerns over its initial water content.

Myth #3

Lightweight concrete is more expensive.

Another common industry misconception is that lightweight concrete costs more than normal weight concrete. While it is true that aggregate processing and shipping lead to higher per cubic foot costs, the overall reduction in concrete weight offsets the increased unit cost and can lead to savings. These economies are realized in a few ways, regardless of geographical location.

The unit weight of the concrete is reduced from about 145 pcf for normal weight concrete to about 115 pcf for lightweight concrete (using equilibrium density with adequate drying with time). This is an overall reduction of 21 percent. These savings compound in buildings requiring a fire-rated floor system because a lightweight concrete floor can be thinner than a normal weight concrete floor and provide the same fire rating. In either scenario, lightweight concrete reduces the floor slab density and overall load. With less material needed for the framing system and foundation, economies across the whole building are typically more than enough to offset the additional cost of lightweight concrete. More information on these savings can be found in the Five Story Commercial Building Study (Utelite Corporation, 2017).

Looking Ahead

With these three common structural lightweight concrete myths busted, readers can rest assured that the hardworking material remains a viable solution for the built environment. In fact, with demand for longer floor spans, minimal floor thicknesses, and lighter dead loads, structural lightweight concrete will stay at the forefront of commercial building.■

This article, all or in part, was published on the ESCSI website, June 2020. It is reprinted with permission.

References

Byard, B.E., and Schindler, A.K. (2010) Cracking tendency of lightweight concrete. Highway Research Center, Auburn, AL.

Craig, P. A. (2011) Concrete Floor Drying Study for the Expanded Shale, Clay and Slate Institute. Expanded Shale, Clay and Slate Institute, Chicago, IL. 13 pp.

TBSE, Inc., Letter report: Five Story Commercial Building Study for Utelite Corp., October 20, 2017.