A recent webinar on the “10% Rule” included in the 2018 International Existing Building Code (IEBC), attended by the author, discussed an exception in the code’s Section 502.5 that allows existing structural elements to remain unaltered if an addition to that structure results in a less than 10% increase in the element’s demand-to-capacity ratio. After the webinar, there remained the question, where was the companion webinar, the “5% Rule?” The 5% rule, otherwise known as the Prescriptive Compliance Method, is more straightforward and widely used. It is contained in IEBC Section 502.4 and states the following:

Any existing gravity load-carrying structural element for which an addition and its related alterations cause an increase in design dead, live or snow load, including snow drift effects, of more than 5 percent shall be replaced or altered as needed to carry the gravity loads required by the International Building Code for new structures.

It is important to note that this exists in the Additions section of the code, but its language and intent are echoed in section 503.3 for Alterations. The Alterations section also includes an additional exception for roofing, which allows for a second layer of roof covering weighing 3 pounds-per-square-foot or less to be applied over an existing roof. This particular example is discussed in more detail later in this article.

The Prescriptive Compliance Method intends to allow for some flexibility for contractors and building professionals when doing simple additions, alterations, or maintenance work. It is unreasonable to require an engineer to evaluate an existing structure’s adequacy every time something minor arises. It can also be a daunting task when there is a lack of original plans and calculations, despite the addition being as simple as a new waterproofing material being applied or installing new ductwork. It is also an effort to provide an upper boundary for what can be done before triggering more strenuous requirements, as this is sometimes a grey area. The question of who is qualified to determine the original weight and whether the addition is within 5% remains, but that could be discussed to no end and the line has to be drawn somewhere.

This article is an effort to clarify the rule and warn about using it. These portions of the IEBC are very interesting and, more importantly, dangerous to the general public if there are engineering, design, and/or construction individuals utilizing them without a complete understanding of the underlying principles. The author has encountered some situations where this rule was used improperly. The following can recommend ways to proceed should any readers come across similar situations.

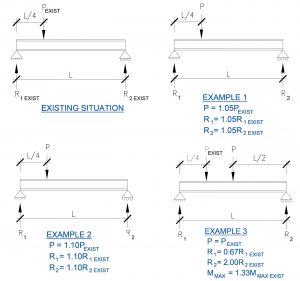

It is best to start with simple examples and then delve into some more advanced situations.

Example 1

An HVAC unit on the roof of a building needs to be replaced. The existing unit weighs 500 pounds, while the replacement unit weighs 525 pounds. If an engineer is trying to determine if the supporting roof beams are structurally adequate, and assuming size and anchorage locations/requirements are equal for both units, then the beams would fall within the 5% rule. The unit could be replaced without further structural analysis and without analyzing the beams or providing designs to bring them up to current building code requirements (assuming that excessive decay, corrosion, or other adverse effects are not present in the roof beam from the time of original construction).

Example 2

Assuming the same building, roof beams, and existing HVAC unit, the replacement unit will now weigh 550 pounds. This would add a design gravity load greater than 5%. Thus, per IEBC Section 502.4, it would require the supporting roof beams to be analyzed and redesigned as required to carry the full new load under the current governing code provisions.

Stopping right there would leave readers with a very clear and basic picture of what the 5% Rule means. However, a few more things need to be discussed concerning this rule because they are essential to public safety in structures.

What would happen if there were a different situation where the unit has not changed weight, but the new unit’s location was shifted a little along the length of the supporting beam? Has the gravity load to the beam increased? It has not, so the change should still be acceptable under section 502.4, right? Wrong. The following example illustrates this.

Example 3

Assume that the original unit was located at the ¼ point along the beam’s length, and the new unit is to be placed at mid-span. Both units weigh 500 pounds. The design gravity load has not increased above 5%, but the moment demand on the beam has increased by 33%.

In this situation, depending on the original moment demand-to-capacity ratio of the beam, it is likely that the beam is overstressed based on the original design building code used. Unfortunately, this is a very common mistake that some people make when thinking they are following the 5% rule. Engineers know that moving a load will have this effect, but sometimes there are people who think they are following the building code, citing the 5% rule, and move on. In this particular case and those like it, the situation would result in an unsafe condition and a possible collapse at worse.

The code section for this 5% Rule applies to all “gravity load-carrying structural elements.” This encompasses not only beams and other spanning members but also the connections. If the HVAC unit’s location moves, then the load carried by the beam connection at the end that the unit shifted toward has now increased, as shown in Example 3 above. Whether or not that increase is greater than 5% is a function of the weight change and the location shift.

The Dangers of Compounding

Another improper use of this rule is when it is applied more than once over the life of a structure. In certain industries, it is common practice to add to existing structures repeatedly. One example is when new roofing material is stacked on top of the existing roof rather than stripping the old material. As previously discussed, there is an exception in the code that allows for this to happen once “over an existing single layer of roof covering.” Roofing may not weigh that much, but if this occurs multiple times, it could become a danger. There have been instances where the roof starts to visibly sag in warning or collapse altogether when wind or rain loads push the members over their capacity.

There is typically a lack of existing drawings for the structures and even fewer structural calculation packages. Sometimes it is difficult to determine if a portion of the structure was a future addition or part of the original design. This leads many industry professionals to want to rely on the 5% Rule for simplicity due to a lack of existing information. The problem is that using the 5% Rule more than once on the same structure or structural element is in violation of the rule and can have a compounding effect. Say one project added 5% weight ten years after original construction, then another project adds another 5% ten years after that. The original structure has now had not just 10% of the original weight added (which would violate the Rule on its own), but actually, 10.25% weight was added (5% plus 5% of 105%.) Unfortunately, this can be a common occurrence and should make any engineer uneasy if noticed on an existing structure in the field.

Roofing layers stacked on top of each other, causing structural members to sag

under the weight. (photo source: https://bit.ly/3aLYxIc)

The author has seen numerous examples of this in the oil and gas industry, where pipes are continually being added and rerouted on existing structures. Suppose a full structural support evaluation is to be avoided. In that case, the engineers involved in these projects must determine if the addition or alteration is within 5% if there have already been additions and their effects. This task is also compounded by the fact that piping loads in this industry occur not just from gravity, live, wind, and seismic forces but also from thermal and pressure expansion/contraction of the piping and its contents.

Additional Considerations

Consider the case where the 5% Rule was used correctly in accordance with the code language and intent. The structure is most likely going to be OK, considering that most engineers do not push their demand-to-capacity ratios to 95% from the start. Additionally, statistical factors are applied to loads, assuming Load and Resistance Factor Design (LRFD), that could help offset a 5% gravity load increase. However, how would the structure fare if made of steel, located near the ocean, and showing signs of significant corrosion? Sure, it may be within the code to blindly apply new loads, but this could lead to failure due to the assumption that the current strength of a structure is equal to the original design strength. When evaluating existing structures, engineers know to take these things into account, not make blind assumptions.

Conclusion

Engineers have the education and the skills to quantify and investigate existing structures accurately. Rather than rely on vague code language, they should use that knowledge to carry out projects correctly and safely. Of course, the argument against this is that it will require more work like a site visit, extra calculations, etc. This ultimately means it will be more expensive and, for a seemingly minor modification, it could be deemed not worth the expense. A response to that is: what is more expensive, the initial investigation or a collapse of the structure leading to a lawsuit? The risks and outcomes of projects need to be weighed similarly to how the LRFD method weighs loading and member strengths. The monetary and mental cost of stamping and signing off on a structure that collapses needs to be factored in.

Yes, the 5% Rule is used by some outside of the engineering profession, and some may suggest that the language be removed from the code entirely to prevent it from being used by those who do not fully understand it. There is a common phrase, “I know just enough to be dangerous.” In situations such as these, this phrase is entirely accurate and not at all a joke. Someone who knows about Section 502.4 in the International Existing Building Code but fails to understand the implications of utilizing it can very easily create an unsafe situation in an existing structure. Everyone, engineers and others alike, should do the job right and not rely on this rule.■