Where Structural Engineering Meets Fire Engineering

Traditionally, the role of the structural engineer on building projects has focused on structure-related tasks – member sizing, connection detailing, general notes, and specifications for structural components. Design criteria such as fire-resistance ratings, acoustics, and aesthetics have primarily been the architect’s domain. However, when it comes to mass timber, especially tall timber buildings, the structure often contributes to the building’s passive fire resistance while functioning as an exposed finish. This combination of structure, finish, and fire resistance makes the mass timber design process a necessarily collaborative effort between architect and engineer.

This article discusses some of the unique engineering aspects of tall mass timber structures, particularly as they pertain to fire and life safety. These requirements are based on three new construction types introduced in the 2021 International Building Code (IBC) – Type IV-A, IV-B, and IV-C – which allow up to 18 stories of mass timber. Changes to the 2021 IBC are also discussed in the Code Updates article (Hunter and Koch), June 2020 online issue.

A baseline requirement for tall timber structures utilizing one of the three new construction types is that they are constructed of either mass timber or noncombustible materials (or a combination thereof). Mass timber can encompass well known and widely used products such as glue-laminated timber (glulam) and nail-laminated timber (NLT), as well as newer panelized products such as cross-laminated timber (CLT). The definition of mass timber adopted for the 2021 IBC is:

Structural elements of Type IV construction primarily of solid, built-up, panelized or engineered wood products that meet minimum cross-section dimensions of Type IV construction.

In practice, mass timber, as defined in the IBC, is an umbrella term that includes heavy timber elements. Materials must meet minimum size requirements that give them intrinsic fire-resistance to qualify as heavy timber under Type IV-HT. Mass timber systems utilized in Types IV-A, B, and C also have a minimum required fire-resistance rating (FRR).

Exposed vs. Protected Timber

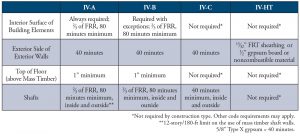

When mass timber elements are used in tall timber structures, the construction type definitions contained in IBC Sections 602.4.1, 602.4.2, and 602.4.3 provide guidelines for whether the timber may be exposed on the building’s interior or needs to be covered with noncombustible protection. General allowances for exposed timber are noted as follows and further explained in the Table.

- Type IV-A: No exposed timber is permitted

- Type IV-B: Limited exposed timber is permitted as follows:

o Ceilings (including integral exposed beams) up to 20% of floor area in a dwelling unit or fire area*, or

o Walls (including integral exposed columns) up to 40% of floor area in a dwelling unit or fire area*, or

o A combination of each using sum of ratios (actual exposed/allowable exposed) not to exceed 1.0 - Type IV-C: All exposed timber is permitted*

*Exceptions: no exposed timber is allowed at shafts, within concealed spaces, or on the exterior side of exterior walls. Concealed spaces and shafts are discussed in greater depth later.

Contribution of Noncombustible Protection to FRR

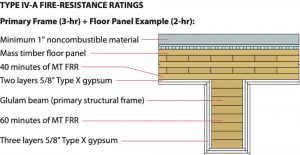

When noncombustible protection is required over timber elements, it must provide at least two-thirds of the FRR. Two prescriptive options are presented in IBC 2021 Section 722.7.1 – 25 minutes for each layer of ½-inch Type X gypsum board, and 40 minutes for each layer of 5⁄8-inch Type X gypsum board.

Contribution of Mass Timber to FRR

As noted, mass timber elements requiring noncombustible protection must achieve a minimum of two-thirds of their FRR from the noncombustible materials. The remaining one third must come from the inherent fire resistance of the mass timber element (Figure 1). In applications where the timber is exposed, the full FRR required in IBC Table 601 must be achieved through the inherent fire resistance of the mass timber element.

In either of these circumstances, IBC Section 703.2 provides options for demonstrating FRRs through testing in accordance with ASTM E 119, Standard Test Methods for Fire Tests of Building Construction Materials, (or UL 263, Standard for Fire Tests of Building Construction and Materials) or one of six alternatives listed in IBC Section 703.3.

Item 3 of IBC Section 703.3, which permits the use of calculations in accordance with Section 722, is frequently used to demonstrate the FRR of mass timber. Section 722.1 states: The calculated fire resistance of exposed wood members and wood decking shall be permitted in accordance with Chapter 16 of ANSI/AWC National Design Specification® for Wood Construction (NDS®). Chapter 16 of the NDS can be used to calculate up to a 2-hour fire-resistance rating for a variety of exposed wood members, including solid sawn, glulam, structural composite lumber, and CLT, and is discussed in more depth in the Hunter and Koch article.

Successful ASTM E 119 fire tests have been completed on numerous mass timber elements and assemblies, achieving fire-resistance ratings of 3 hours or more. Additional tests by manufacturers and others are ongoing.

To help building designers compare options, WoodWorks has compiled a web-based inventory of completed mass timber fire tests. The Inventory of Fire Resistance-Tested Mass Timber Assemblies & Penetrations (WoodWorks, 2019) is updated as new tests become available.

For additional information on both the calculation-based method and ASTM E 119 testing method of demonstrating the FRR of mass timber elements, see Fire Design of Mass Timber Members (WoodWorks, 2019).

Connections

In addition to FRR requirements for structural wood members such as beams, columns, and panels, connections between members (e.g., beam-to-column connections) must have sufficient protection to provide the same fire-resistance rating. Section 16.3 of the NDS states:

Wood connections, including connectors, fasteners, and portions of wood members included in the connection design, shall be protected from fire exposure for the required fire-resistance time. Protection shall be provided by wood, fire-rated gypsum board, other approved materials, or a combination thereof.

As noted in NDS Section 16.3, options for protecting connections include:

- Concealed connections protected by charring of wood

- Fire-rated gypsum board

- Other materials or methods approved by the Authority Having Jurisdiction

Technical Report 10 (TR10), Calculating the Fire Resistance of Wood Members and Assemblies (American Wood Council, 2018), provides a discussion on connection protection options, including unique design considerations associated with wood as a covering material.

Figure 2. Example fire-protected beam to column connection. Courtesy of Alexander Schreyer, University of Massachusetts, Amherst.

There are two common approaches to protecting connections for the required FRR. One method is to entirely conceal the connection within the structural timber members (Figure 2). Alternatively, connections may be protected by applied wood or gypsum coverings. Aesthetics and required member and covering thicknesses are key considerations when determining the most appropriate solution.

Several glulam beam-to-column connection fire tests have been completed, and additional testing is anticipated as more connections and project specific requirements are developed. The WoodWorks web-based inventory of completed mass timber fire tests is updated frequently as new tests are completed.

A qualified professional can also be retained to perform an engineering analysis on a proposed connection detail to evaluate its performance under fire conditions. The 2021 IBC includes language specific to the temperature profile of connections in tall timber structures to support such analyses.

Concealed Spaces

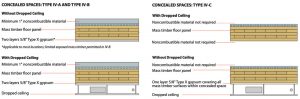

Most mass timber building designers aim to expose as much of the timber as practical and as the code allows; however, there are often areas that require a dropped ceiling (e.g., to conceal mechanical, electrical, and plumbing services). Concealed spaces have unique requirements to address the potential of fire spread in non-visible areas of a building. Section 718 of the IBC includes prescriptive requirements for protection and/or compartmentalization of concealed spaces using draft stopping, fire blocking, sprinklers, and other means. For information on these requirements, see the WoodWorks Q&A, Are sprinklers required in concealed spaces such as floor and roof cavities in multi-family wood-frame buildings? (www.woodworks.org)

While concealed spaces have not historically been permitted in Type IV structures (per IBC Section 602.4), this changes with the 2021 IBC. Type IV-HT construction and all three tall mass timber sub-types will permit concealed spaces when protective measures are taken. Specifically, for tall timber buildings, no combustible materials that form the concealed space (i.e., the underside of a mass timber floor or roof panel) may be left exposed within that space.

Concealed spaces are permitted in construction Types IV-A and IV-B when any mass timber surface within the concealed space is protected with noncombustible materials that contribute two-thirds of the required FRR. For floors, this typically means 80 minutes of protection (2 layers of 5⁄8-inch Type X gypsum) on the underside of the mass timber panel. At roofs, the lower FRR results in a proportionally lower amount of noncombustible FRR contribution. Concealed spaces are permitted in construction Type IV-C when any mass timber surface within the concealed space is protected with noncombustible materials that provide 40 minutes of protection (1 layer of 5⁄8-inch Type X gypsum). Figure 3 illustrates the allowances and common assembly options.

Shaft Enclosures

Provisions addressing materials permitted in shaft wall construction can be found in both the shaft enclosures section (713.3) and the fire barriers section (707.2) of the code. These sections state that fire barriers can be constructed of any material permitted by the building’s type of construction. As noted, Types IV-A, IV-B, and IV-C permit the use of mass timber or noncombustible elements. This allowance also applies to shaft enclosures, with one exception; Section 602.4 of the 2021 IBC notes the following regarding shaft walls in buildings taller than 12 stories or 180 feet:

In buildings of Type IV-A, B, and C, construction with an occupied floor located more than 75 feet above the lowest level of fire department access, up to and including 12 stories or 180 feet above grade plane, mass timber interior exit and elevator hoistway enclosures shall be protected in accordance with Section 602.4.1.2. In buildings greater than 12 stories or 180 feet above grade plane, interior exit and elevator hoistway enclosures shall be constructed of noncombustible materials.

Following these code provisions, mass timber may be used as a shaft enclosure material in tall wood buildings (Figure 4) – except Type IV-A buildings that exceed 12 stories or 180 feet.

Figure 4. Example of a tall mass timber structure. Courtesy of Generate Architecture and Technologies + MIT – John Klein.

As stated in IBC Section 713.4, shaft enclosures are required to have an FRR of not less than 2 hours when connecting four or more stories. An FRR of not less than 1 hour is required for shaft enclosures connecting less than four stories. Shaft enclosures are also required to have an FRR not less than the floor assembly penetrated. In all three tall mass timber construction types, the required floor FRR is 2 hours. Shaft enclosures that penetrate a floor assembly in any of the new types require a 2-hour rating, even if the building is less than four stories tall. Shaft walls that are also bearing walls in Type IV-A construction require a 3-hour FRR per IBC Table 601.

Noncombustible Protection of Mass Timber Shaft Walls

When used as shaft walls in Type IV-B or IV-C buildings (or IV-A buildings that do not exceed 12 stories or 180 feet), mass timber must be covered on both faces with noncombustible materials, as indicated in the definitions of the individual construction types. Mass timber shafts in Type IV-A and IV-B construction must be protected with noncombustible materials that contribute two-thirds of the wall’s required FRR. Mass timber shafts in Type IV-C buildings must be protected with noncombustible materials that provide a minimum of 40 minutes of protection (1 layer of 5⁄8-inch Type X gypsum).

Other Considerations

In addition to the FRR and contribution of noncombustible coverings, designers must consider factors such as acoustics and structural loads when choosing mass timber elements such as shaft wall assemblies for tall wood buildings. For information on the acoustical design of mass timber wall assemblies, see Acoustics and Mass Timber: Room-to-Room Noise Control (McLain, WoodWorks, 2018) and its accompanying Inventory of Acoustically-Tested Mass Timber Assemblies (WoodWorks, 2019).

Detailing items such as primary frame connections and assembly intersections also requires consideration of these factors, and it is often beneficial to discuss proposed details with the Authority Having Jurisdiction early in design. For shaft walls, some projects have utilized mass timber walls that are multiple stories per lift, resulting in adjacent mass timber floor panels being supported by the shaft walls via a ledger. Other projects have used a platform-frame approach, with shaft walls lifted in one-story increments and adjacent floor panels bearing on the walls. Speed of construction, structural loading, cumulative shrinkage and crushing potential, and fire barrier continuity are all factors that will help inform the detail selection.

Although not necessarily required to achieve the floor assembly’s FRR, floor assemblies in Types IV-A and IV-B construction require a minimum 1-inch-thick noncombustible covering. Examples include a poured concrete or gypsum layer, or sheets of noncombustible board products.

Conclusion

With significant interest in tall timber construction across the U.S., it is becoming more important for structural engineers to understand the key fire and life safety issues and how they interface with structural design. While construction types and fire-resistance ratings are not commonly the domain of structural engineers, this is often the case with mass timber projects, and an understanding of these topics can help engineers provide more effective solutions.■

References

WoodWorks. (2019). Inventory of Fire Resistance-Tested Mass Timber Assemblies and Penetrations. Retrieved from https://bit.ly/2SxKTQE.

McLain, R., S. Breneman. WoodWorks. (2019). Fire Design of Mass Timber Members: Code Applications, Construction Types, and Fire Ratings. Retrieved from https://bit.ly/3aY8ujG.

American Wood Council. (2018). Technical Report No. 10 (TR-10): Calculating the Fire Resistance of Wood Members and Assemblies. Retrieved from https://bit.ly/3b9EuSc.

WoodWorks. (2018). Are sprinklers required in concealed spaces such as floor and roof cavities in multi-family wood-frame buildings? Retrieved from https://bit.ly/2YA5Vl9.

McLain, R. WoodWorks. (2018). Acoustics and Mass Timber: Room-to-Room Noise Control. Retrieved from https://bit.ly/2KZQXwV.

WoodWorks. 2019. Inventory of Acoustically-Tested Mass Timber Assemblies. Retrieved from https://bit.ly/3dgDgWs.