Design-Oriented Finite Element Modeling

Structural engineers typically design standard connections that can be solved in several minutes using Design Guides, spreadsheets, or simple software. The non-standard connections are the real challenge. The 80/20 rule applies: 80% of the time is spent on 20% of connections. Non-standard connections are not only more challenging to design but also more costly and prone to errors. Finite element modeling comes to the rescue, allowing the calculation of complicated problems automatically. It has been used mostly for research purposes at universities or very large and costly projects. However, it is now becoming available for even small design firms to use on a daily basis. The desire for architecturally appealing and structurally complex solutions can lead to the use of novel, nonredundant systems with no prior record of proven performance. This makes safe, reliable engineering tools especially critical.

Connection Design and Modeling

In connection design, the Component Method, where the connection is divided into simple discrete components and a basic model is constructed, has become a standard method for those designing with the Eurocode. Design rules are provided to determine the strength and stiffness of each component. AISC Design Guides for steel connections describe methods for particular joints, but the Component Method is more general and is implemented in most software for structural engineers. The components are designed by standardized analytical models, and internal forces are derived based on engineering practice. In current European research into steel connections, the design properties of components are refined or newly developed. The aim is to make the Component Method also available for conditions such as joints of composite steel-concrete structures or for, until now, non-standard connectors (e.g., hollo-bolts). Research into the deformation capacity of components is also being carried out, which is useful, especially for cyclic loading during an earthquake.

The design methods are still available only for the most common connection types. The Component Method model employs significant simplifications, containing only several springs with linear stiffness. The neutral axis is approximated for some loading cases, and the weakness of the method is revealed for a combination of loading, e.g., by biaxial bending moment.

An alternative is the use of finite element modeling, which is useful, especially for non-standard connections. The model is divided into simple small elements with defined properties by the process of meshing. The stress and strain in each element are determined by a numerical method. Two model types are recognized:

- Research-oriented finite element model (ROFEM)

- Design-oriented finite element model (DOFEM)

A standard approach for ROFEM is to perform an experiment and then create an advanced numerical model with fine meshing utilizing measured material properties and initial imperfections, often including residual stresses. The results of ROFEM should fit as closely as possible to the experimental results. By this process, a validated ROFEM is created, which may be used for further numerical experiments, in which the design material properties are often used. The influence of the main parameters is examined in a sensitivity study, where these parameters are varied and their effect on the load resistance is investigated. The creation of a validated ROFEM is very time consuming and costly, yet still cheaper and more feasible than experiments. ROFEM also provides further information that is difficult to obtain by experimental measurements.

The design-oriented finite element model uses design material properties (e.g., bilinear material curve with von Mises yield criterion instead of a true stress-strain material diagram) and standard safety factors. The DOFEM should ideally contain a significantly reduced number of finite elements and nodes compared to a ROFEM. The reduction in the number of elements and nodes significantly reduces computational effort. However, it must be proven by a mesh sensitivity study that the results are not affected significantly by this reduction. The DOFEM must be compared to either a validated ROFEM or traditional design methods – this process is called verification.

A special type of DOFEM is a model using the Component-based Finite Element Method (CBFEM). The method is a synthesis of the Component Method and the finite element method. The plates are modeled by shell elements and the components, e.g., bolts or welds, by nonlinear springs with their properties based on design codes and state-of-the-art research. CBFEM provides code checks of failure modes that are very difficult to capture by finite element analysis alone, such as crushing of concrete in compression or weld fracture. CBFEM removes the restrictions and most simplifications used in the Component Method. The neutral axis and forces in components for any type of load combination are determined by the finite element method.

Validation and verification ensure that the finite element analysis of the model is correct. The whole process is described in an example of a block shear of a bolt group.

Validation of ROFEM

The experiments by Huns et al. performed at the University of Alberta in 2002 are used for validation of a ROFEM created by Sekal in 2019 in ANSYS software (Figure 1). The tested gusset plates are 0.26 inches thick, the bolts have a diameter of ¾ inch, and the bolt holes are match drilled. Therefore, the bolts are directly in bearing. A true stress-strain material diagram is used. Only the thinnest plate predicted to fail is modeled. The model contains 190,264 hexahedron elements and needs around 26 hours of computational time on a dedicated server. The ROFEM model shows excellent agreement with the test results (Figure 2). (The model is considered validated, and it can be used for further parametric studies such as the effect of bolt pitch or edge distance on the block shear resistance.

Figure 2. Geometry of specimen T2 (dimensions in mm); load versus deformation plot, ROFEA, and experimental curves.

Verification of CBFEM Model

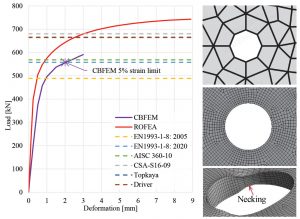

A DOFEM using CBFEM is created based on the numerical experiments performed using the ROFEM validated on experiments. The models are compared to each other to prove the validity of CBFEM. This way, the effect of random imperfections of the specimens in experiments is removed. The DOFEM is further compared to several analytical models for block shear resistance of bolted connections. The models from AISC 360-10, CSA S16-09 (Canada), EN 1993-1-8:2005 (Eurocode), and prEN 1993-1-8: 2020 (Eurocode-draft) codes are investigated. Furthermore, the results of analytical models by Driver et al. (2005) and Topkaya et al. (2004) are presented.

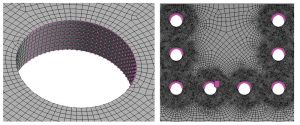

The design-oriented CBFEM model uses shell elements with a rather coarse mesh. The finite element model is created in the background of the software and does not require a high level of expertise about the numerical method from the user. The mesh is predefined near bolt holes. Bolts are modeled as nonlinear springs which are connected to the nodes at the edge of the bolt holes by links with nonlinear load-displacement behavior. The bilinear material diagram with insignificant strain-hardening is used for plates. The slight slope of the plastic branch improves the convergence of the solver, and the impact on the precision of results is negligible. The limit resistance of a group of bolts in bearing is determined when the plastic strain at the plate reaches 5% (EN 1993-1-5: 2005). The bearing and hole tear-out resistances of each bolt are checked by formulas from the appropriate code. The computational time on a personal computer is in seconds.

Figure 3. Load versus deformation curves – verification results; mesh around bolt hole – DOFEM (upper) and ROFEM (lower) (Sekal, 2019).

The comparison is shown in Figure 3. All design models are conservative compared to this experiment and corresponding ROFEM. The results of the CBFEM model and ROFEM do not match each other perfectly because match drilled bolts were used in the experiments. The shear stiffness of a bolt in the CBFEM model is set to conform to the average behavior of a bolt in standard holes. The resistance of the CBFEM model is smaller due to the neglected strain-hardening of plates and small limit of plastic strain; the guaranteed strain at fracture of structural steel in tension must be at least 15% (Figure 4).

Figure 4. Bolted stiffened end plate connection: plastic strains on a deformed CBFEM model (deformation scale 3) and reliability graph.

On the other hand, the coarse mesh leads to higher load resistances. The resistance of the CBFEM model nearly matches the resistance determined by AISC 360-10 and prEN 1993-1-8: 2020. It is conservative compared to the model by CSA S16-09 and, at the same time, unsafe compared to EN 1993-1-8: 2005. The current Eurocode analytical model is known to be too conservative and will be modified in the next generation published in the final draft of prEN 1993-1-8: 2020.

Conclusion

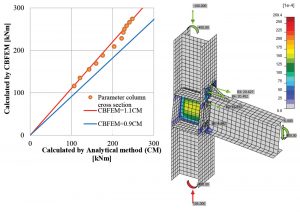

The design-oriented finite element model using CBFEM is extensively verified, and the studies are published. It is implemented in several commercial software, such as IDEA StatiCa or Hilti Profis. The results of finite element analysis are first compared to the traditional analytical design procedures in current codes. The aim is to differ from the analytical procedure by 10% at most. If CBFEM provides unconservative results, the model is also verified against ROFEM validated by experiments. Analytical models often contain several simplifications, e.g., rigid base plate assumption or linear interaction of bending moments around two axes perpendicular to each other. Finite element models are, from their underlying principle, much more precise.

Often, the structural engineer is required to make conservative assumptions and educated guesses when designing non-standard joints, which are not described in Design Guides. CBFEM is a tool able to calculate such estimates in minutes, and provide not only design load resistances but also a visual presentation of behavior and a risk of possible failure modes.■

References

Latour, M., Rizzano, G. A theoretical model for predicting the rotational capacity of steel base joints. Journal of Constructional Steel Research. 2013, 91, 89-99. DOI: 10.1016/j.jcsr.2013.08.009. ISSN 0143974X.

Gödrich, L., Wald, F., Kabeláč, J., Kuříková, M. Design finite element model of a bolted T-stub connection component. Journal of Constructional Steel Research. 2019, 157, 198-206. DOI: 10.1016/j.jcsr.2019.02.031. ISSN 0143974X

Wald, F. et al. Benchmark cases for advanced design of structural steel connections, Prague, Česká technika, 2019.

Sekal D. Analysis of Block Shear Failure, Diploma Theses, TU Munich and CTU in Prague, 2019.

Huns B. B. S., Grondin G. Y., Driver R. G., Block Shear Behaviour of Bolted Gusset Plates, Department of Civil and Environmental Engineering, University of Alberta, 2002

Robert G. Driver, Gilbert Y. Grondin, Geoffrey L. Kulak, Unified block shear equation for achieving consistent reliability, Journal of Constructional Steel Research, 2006, 62, 210–222.

Topkaya C., A finite element parametric study on block shear failure of steel tension members, Journal of Constructional Steel Research, Ankara, 2004

AISC 360-10: American National Standard – Specification for Structural Steel Buildings, American Institute of Steel Construction, Chicago, 2010

S16-09: Design of steel structures, CSA Group, Toronto, 2009.

EN 1993-1-8: 2005: Eurocode 3: Design of steel structures – Part 1-8: Design of joints, CEN, Brussels, 2006.

prEN 1993-1-8: 2020: Eurocode 3: Design of steel structures–Part 1-8: Design of joints, Final draft, CEN, Brussels, 2019

EN 1993-1-5: 2005: Eurocode 3: Design of steel structures – Part 1-5: Plated Structural Elements, CEN, Brussels, 2005.

IDEA StatiCa Connection: Theoretical background. Available at https://resources.ideastatica.com ANSYS®, Help System, ANSYS Parametric Design Language Guide, ANSYS, Inc.