Light wood framed residential construction has historically performed well in seismic events. The combination of low mass, redundancy, and damping resulting from damage of finishes allow the buildings to see large inelastic deformations without collapse. In high-end residential construction, this may no longer be the norm. Clients are choosing finishes that are heavier and more brittle, such as natural stone veneers and tile floors over lightweight concrete topping. The amount of glass versus a solid wall is ever increasing. Engineers are pushing the limits of wood as a construction material with long open spans and cantilevers, increased shear wall aspect ratios, and higher ceilings. This results in heavy, brittle residential structures, with less wall length and redundancy, that will probably see significant damage in a moderate earthquake and potentially partial collapse under the maximum considered earthquake (MCE). The resulting financial losses could be enormous, especially when the loss of contents is considered along with the damage to the building.

A few years ago, FTF Engineering was asked to design a high-end single-family residence that could withstand an MCE with minor damage. The task was not easy since the architectural design included an open floor plan with tall ceilings, large glass surfaces, a long cantilever deck, and a cantilever roof with a large rectangular opening. For their new home, the owners selected a steeply sloped, wooded site on the Portola Valley Hills, offering expansive views of the entire San Francisco Bay Area. They wanted a modern house without compromising on space and safety, although the site is just over 1 mile from the San Andreas Fault. To realize the owners’ wishes, the firm decided to look beyond the ordinary code residential design and explore all the possibilities that advanced seismic structural design (ASSD) can offer. Considering the topography and the architectural challenges of this three-story building, FTF selected a lateral force resisting system that largely improved the expected seismic performance of the structure with a small overall construction cost increase.

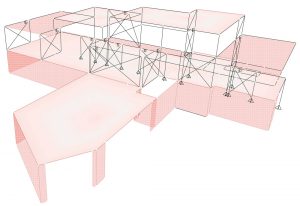

In the plan view, the building is a “T” shape. The long leg of the “T” is a two-story concrete structure that houses an impressive 5000-bottle wine cellar and ample storage space in the concrete basement. Above the wine cellar is a 3-car garage over a concrete-on-metal deck floor with a green deck above supported by concrete shear walls that provide the needed strength to this wing of the house. The head of the “T” is the main residence, a 4400-square-foot modern architectural masterpiece. The sound-insulated basement includes a game room with pool access. The living quarters are above and include a spacious master suite with a private deck, additional bedrooms, and bathrooms. The 3rd story is for entertainment and includes all the utility spaces, a large lounge surrounded by multi-panel sliding doors that open onto a large cantilevered deck, and a living room with clerestory windows on all four sides. Steel beams and columns span the large, open spaces and frame the clerestory. Wood stud walls and engineered wood joists merely infill the space between the steel structure. Thirteen steel braced frames with viscous fluid dampers, by Taylor Devices Inc., provide the lateral force resistance for this wing of the house. The frames are hidden inside the stud walls and connected with steel collectors to the diaphragms. Tucked in the back corner of the upper floor is the owner’s private office with a special picture frame to show off one of the dampers. To separate the “stiff leg from the flexible head,” a two-way sliding connection on top of the short concrete wall, shared between the two wings, provides enough displacement for the roof of the main house to move independently from the garage.

Before settling on ASSD, a conceptual code-based design was developed that consisted of multiple steel special moment frames and plywood shear walls. The challenges with this design approach were to hide the moment frame columns within the open concept floor plan and provide enough plywood shear walls without reducing the length of large façade glass surfaces. Both the owners and the architect preferred an alternate solution that would preserve the architectural expression and also provide higher seismic performance, hence the selection of ASSD. The only concern the clients had was the potential for increased construction cost; therefore, the general contractor priced both options and the cost of the ASSD represented approximately a 5% increase of total construction cost.

After the decision was made to change to steel braced frames with fluid viscous dampers for the residence, the first step was to determine how best to integrate the dampers into the lateral system and then run a preliminary analysis to determine their effectiveness. Viscous dampers dissipate the energy of a seismic event by forcing a fluid through an orifice during deflection in either direction along the length of the damper. The dampers need to deflect to dampen the energy but also need to be strong enough to limit the seismic drift to levels that will not damage finishes during the maximum expected earthquake for the site. Studies have shown that most of the damage to finish materials occurs beyond 1% drift; therefore, this deflection limit was set for the dampers. The damper configuration was horizontal, with one end attached to the horizontal diaphragm and the other end supported by a diagonal brace system. The brace is designed to support the full axial load of the damper, without large elongations, and transfer it to the foundation. A sliding connection was used where the brace connects to the damper and diaphragm to provide out of plane support.

The design firm performed a time history analysis on individual frames using CSI America’s SAP2000 non-linear analysis program in accordance with ASCE 7-10, Chapter 18, Seismic Design Requirements for Structures with Damping Systems, to determine the size, deflection, and damping coefficients of the damper frames. For the analysis input, the project geotechnical consultant prepared a site-specific ground motion study and three pairs of scaled ground motions in accordance with ASCE 7-10, Chapter 16, Seismic Response History Procedures. Before the analysis, the seismic mass was distributed to individual frames using the flexible diaphragm design approach. The analysis results determined the maximum damper force by adjusting the damper coefficient and velocity exponent until the story drifts dropped below 1%, which was later used to custom-manufacture each damper. With the damper frames providing all the lateral resistance during large seismic events, the exterior-framed walls sheathed in plywood and the interior drywall surfaces provide enough stiffness to keep the structure stable during small seismic or wind events.

Recognizing the uniqueness of this project, the clients agreed to outfit the house with 11 ground motion sensors, including one in each direction at each level of the house and 3 outside near the driveway to serve as a baseline. The sensor work was done by the Center for Engineering Strong Motion Data. To date, these sensors have not recorded any substantial ground motion data but, with its proximity to the San Andreas fault, ground motion is imminent.

Dampers in residential construction are somewhat rare, and this project was a first for the design team and contractors. Some of the lessons learned along the way, implemented by the design team since, include:

The Plan Checker is your Friend – Small municipalities have limited resources and are mainly familiar with a conventional residential design plan check. Knowing that, it is essential to include the local building department early in the design process. This will facilitate communication between the design and plan check teams and expedite the approval process. Many times, small building departments outsource to third-party plan check agencies, so it is even more critical that they are aware early of the complexity of the design and assign the project plan check to the right person.

Collaboration with the Architect is Key – FTF’s philosophy is to enable the architectural expression through smart engineering solutions, by taking a step back and letting the architecture take center stage. Design solutions should organically follow the architectural design and work in symbiosis with the rest of the building elements. By utilizing small braced frames supplemented with fluid viscous dampers, they could be hidden inside walls, enabling the architect to implement his and the clients’ vision for this modern residence.

Work Closely with the Damper Manufacturer and the Contractor – There is a lot of coordination in any construction project of this magnitude. Adding in dampers, steel braced frames, and green roofs require even more coordination at the start. The damper manufacturer should be determined early in the design process so the capacity, stroke, diameter, length, and available end connections can all be taken into consideration while designing the supporting frames. The frames need to be well coordinated with the steel manufacturer because of the tight tolerances. The wood framing needs to be detailed to permit attachment of finishes on either side of the frames while maintaining proper clearances between the moving and non-moving parts.

ASSD Delivers

Advanced structural seismic design for high-end single-family residential construction largely increases the seismic performance of the structure with only a small overall construction cost increase. It is essential that engineers have an open dialog with clients and architects at the beginning of a project and explain the benefits: a better performance during a seismic event, life safety, financial investment protection, and easily achievable architectural design goals.■