Large Scale Research into Durability of Cross Laminated Timber (CLT) Connections

Moisture management plays an essential role in the serviceability and preservation of buildings, particularly when considering wooden structures. This is because wood’s durability can be compromised by the sustained presence of liquid water, while large moisture fluctuations can also impact dimensional stability and mechanical performance. Like any material, wooden structures perform excellently when designed and maintained properly, with many examples that have stood the test of time and lasted centuries (e.g., the Horyu-ji temple in Japan, stave churches in Norway, etc.). While moisture management principles are generally well understood for light frame construction, there are still many questions to be answered regarding moisture performance of large scale, “mass timber” structures, including how fast they wet and dry and how exposure affects long term durability.

This is particularly relevant because, despite requirements for protection of mass timber elements during the service life of the structure (i.e., that they should not be exposed directly to weather), contact with moisture is common during construction and, in the case of leaks, could happen anytime. Moisture monitoring projects at Brock Commons (Vancouver), Carbon12 (Portland), and George W. Peavy Science Center (Corvallis) have demonstrated that CLT elements exposed during construction can generally dry to or remain below acceptable moisture levels during the envelopment process and in service. However, there is still a need for more data and, particularly, research on the propensity for such exposure to affect long term connection durability and service life.

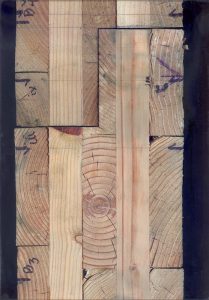

The edge of a CLT panel at a half-lap joint after controlled exposure to heavy rain and subsequent drying – part of the “SMART CLT” project at OSU.

CLT connections are uniquely affected by weathering, in part as a result of the restraining action of the cross laminations. Specifically, while the cross laminations result in higher in-plane dimensional stability, they also induce higher internal stresses between boards and subsequent checking (due to the restraint of moisture-related differential swelling and shrinking). The SMART CLT project, led by Oregon State University (OSU) Assistant Professor Mariapaola Riggio and funded by the TallWood Design Institute (TDI), recently demonstrated that exposure to rain, followed by simulated interior conditions, can result in higher levels of checking and other stress-relief discontinuities, particularly at the edges where connections would occur. While this study explored moisture performance in terms of wetting, drying, and checking, there is still a need to understand the effects of different exposures on the short- and long-term performance of connections.

Moisture monitoring equipment – part of the “Living Lab @ Peavy Hall” study at OSU – installed on a shear wall at the George W. Peavy Hall construction site.

In response to this need, collaborators at OSU and Portland State University (PSU) have been awarded large research grants from the USDA ($500,000) to explore the effects of moisture exposure on the durability of CLT connections. Another grant from the TallWood Design Institute ($250,000) was awarded to a different team to assess CLT durability and develop numerical models to characterize the degradation.

Both projects are led by Arijit Sinha, Associate Professor of Wood Science and Engineering at OSU. The research team for the USDA study consists of people with expertise in the fields of wood durability (Jeff Morrell), non-destructive testing (Thomas Schumacher), accelerated weathering (Fred Kamke), and timber mechanics and structural engineering (Arijit Sinha). For the TDI project, Professors John Nairn and Andre Barbosa join Sinha and Morrell.

“Lack of data and models for this behavior is a significant hindrance to the understanding of the long term behavior of structures, and thus effective service life,” Sinha says.

The team has identified the need to systematically correlate the influence of moisture exposure and wood species on short- to long-term connection durability and mechanical performance.

The MCMEC (Multi-Chamber Modular Environmental Conditioning System), where CLT samples will be exposed to varying environmental conditions during the first stages of the new USDA and TDI funded research.

The research, which aims to quantify degradation, will be conducted in three main stages. In the first stage, Douglas-fir and Lodge-pole Pine CLT samples will be exposed to various wetting conditions and monitored in the Multi-Chamber Modular Environmental Conditioning system (MCMEC) at OSU, a state of the art accelerated weathering device. Wetting conditions will include simulated construction conditions, in-service leaks, and full immersion soaks (to mimic the worst-case scenario). Some samples will be inoculated with decay fungi, while others will be cycled between wet and dry conditions. The samples will be closely monitored to observe wetting and drying trends and durability, all using non-destructive methods (including ultra-sonic wave propagation and full CAT scans).

The second stage will involve destructive assessment of the exposed connections through quasi-static loading at OSU College of Forestry’s structural testing laboratory to determine changes in strength, stiffness, ductility, energy dissipation, and maximum load/deflection. The data from this stage will be used to create a hygro-mechanical model update for the Seismic Analysis for Woodframe Structure (SAWS) 10 parameter model, which will have inputs for moisture and biological conditions.

The third stage will validate the developed model through full-scale testing and will assess a new structural health monitoring methodology for in situ testing of buildings using ultrasonic and acoustic emissions equipment.

The data from this project will be publicly available and will be reported in the form of engineering design guidelines, peer-reviewed publications, student dissertations, and educational seminars. Reporting will be in stages, annually, and the total duration of the project will be 4 years, with expected completion in 2022.■