Mitigating Flooring Issues

Strain is placed on several building materials as construction schedules compress to accommodate building occupancy “as soon as possible.” Add pressures to utilize environmentally responsible products and suddenly traditional construction practices have the potential for problems. A classic example is the interaction between floor coverings, adhesives, and the floor substrate.

One of the most common floor systems used in multi-story commercial construction is concrete placed on metal decking. The concrete is typically covered with some type of flooring material based on the building’s end use. The floor covering is adhered to the concrete with one of many readily available flooring adhesives. This system was successfully used for many decades. However, during the late 1990s and early 2000s, many things changed. Environmentally friendly water-based adhesives were introduced; many floor coverings changed and became less permeable. This combination increased the potential for floor failures because of moisture vapor trapped below the floor coverings. As a result, more attention is now focused on floor coverings, adhesive, and concrete drying times.

Floor Coverings

The type of floor covering used affects the system’s capability to handle moisture. The covering’s ability to allow moisture vapor to pass through can determine what the concrete moisture content needs to be before installing the floor covering. Vinyl composition tile (VCT), vinyl sheet goods, and the type of carpet backing can all have different tolerances to moisture within a flooring system. It is best for the designer to check with the manufacturer prior to specifying flooring materials.

Adhesives

Flooring adhesives are the vital link that connects the flooring to the substrate. There are several choices that vary in composition, quality, and cost. Since the late 1990s, adhesive manufacturers have been forced to reduce emissions when the adhesives are curing. Government agencies mandated that volatile organic compounds (VOCs) be limited in flooring adhesives (Rule 1168) to improve indoor air quality. These mandates sent shock waves through the flooring industry and prompted the development of many new adhesives that were low in VOCs.

These low VOC adhesives are water-based as compared to the previous solvent-based adhesives. The new adhesives are more susceptible to degradation from alkalinity that is carried to the surface of the substrate by moisture. Recommendations were established and published concerning the moisture vapor emission rates (MVER). These rates were established at 3 pounds per 1,000 square feet per 24 hours as measured by ASTM method F 1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride, and 75% relative humidity (RH) as measured by ASTM method F 2170 Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes. Recommendations have also been established concerning pH of concrete floor slabs. Readings of pH below 7.0 and in excess of 10.0 have been known to have a deteriorating effect on flooring adhesives (ASTM F710-08).

Recently, flooring adhesive manufacturers have developed products that can be placed at higher substrate moisture contents. These products have different bases that can handle higher relative humidity (RH) concrete and higher pH surfaces. It is best to check with the individual adhesive manufacturers for their product’s capabilities.

Concrete

The Portland Cement Association describes concrete as a mixture of paste and aggregates or rocks. The paste, composed of Portland cement and water, coats the surface of the fine (small) and coarse (larger) aggregates. Through a chemical reaction called hydration, the paste hardens and gains strength to form the rock-like mass known as concrete.

Concrete placed on metal decks (Figure 1) is either normal weight concrete, typically weighing from 145 to 155 pounds per cubic foot, or lightweight concrete, typically weighing 110 to115 pounds per cubic foot. The structural design and fire rating of the floor assembly dictates the concrete density, strength, and slab thickness. Commonly, concrete is placed utilizing a truck-mounted pump to convey the concrete up to the elevated slab where the concrete is placed on the corrugated metal decking.

The concrete must be proportioned appropriately to meet strength, density, workability, and conveyance requirements. This typically involves adding water and chemicals to the concrete to obtain the desired properties. At a designed water cement ratio (w/c), a known volume of water reacts with the cement and supplementary cementitious materials to hydrate these materials. The water above this amount is called water of convenience and is added to the concrete mixture to improve its pumpability and workability. This water needs to evaporate out of the floor slab to a point where the slab achieves an equilibrium with the ambient conditions. As these conditions change, so does the relative humidity of the slab. The moisture that leaves a slab can bring alkalinity to the surface and interact with some flooring adhesives.

The Expanded Shale Clay and Slate Institute conducted a study in conjunction with adhesive manufacturer representatives to determine the drying time of commonly used floor assemblies. The assemblies were 12 feet by 12 feet and had a minimum of 10 inches of airspace beneath the metal decking. The frames were constructed from steel to replicate suspended floors in a steel frame building so that the assemblies complied with requirements found in construction today. The testing assemblies were constructed to comply with a commonly used Underwriters Laboratories Design No. D916 for a two-hour fire rated assembly. The design requirements are listed in Table 1 (Fire Resistance Directory, Volume 1, UL, 2009).

The testing frames were constructed by a local contractor using full-size metal decking. Slabs 1 and 2 were constructed with metal decking with 2-inch deep flutes. Slab 3 was constructed with metal decking with 2-inch deep flutes and hanger tabs rolled into the decking. The tabs are approximately 1½ inches long and 3⁄8-inch wide and rolled-in every 16 inches. These tabs, used to secure hanger wire for ceiling tile grids, exposed small areas of the underside of the concrete to ambient air. The tabs were evaluated to see if there was any improvement in slab drying because of moisture moving to both the top and bottom of the slabs. No improvement in drying was seen for the deck with rolled-in hanger tabs.

The testing frames were placed in a non-conditioned warehouse in Dalton, GA, under a roof to protect the slabs from rewetting. Large roll-up doors were opened on a daily basis to allow cross ventilation of outside air to simulate conditions found on a job site that is under a roof but has not been enclosed.

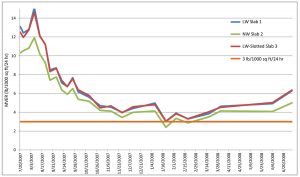

The results of this study showed that both the normal weight and lightweight concretes’ Moisture Vapor Emission Rate (MVER) dried to 3 pounds per 1000 square feet per 24 hours (Figure 2) when tested in accordance with ASTM F1869.

The internal relative humidity for both the normal weight and lightweight concrete never dipped below 80% (Figure 3). These values were measured in accordance with ASTM F2170.

Both the MVER and the internal RH of both types of concrete declined and increased based on the ambient conditions to which the slabs were exposed. The slabs had the lowest MVER and RH in mid-winter when the ambient air was at its driest. As the ambient RH increased coming out of winter, the slab’s moisture content also increased.

When comparing the normal weight and lightweight test assemblies, the lightweight slabs had a slightly higher moisture content throughout the testing period because of the absorbed moisture in the pre-conditioned lightweight aggregate. This additional water is added to lightweight aggregate to prevent slump loss as the concrete is pumped. Since 29.5% more normal weight concrete is needed to achieve the same 2-hour fire rating, the additional water-of-convenience needs to evaporate from the normal weight test assembly. This brought the total water included in the concrete test assemblies closer together, as shown in Table 2. Although there was more water in the lightweight slabs, the drying times were similar to the normal weight slabs.

Recommendations

Now that the individual components of the flooring system have been analyzed, what processes should be followed to work with the pieces and get a successful project that performs as desired? The American Concrete Institute’s document 302.2R-06 Guide for Concrete Slabs that Receive Moisture-Sensitive Flooring Materials offers several suggestions.

Concrete Properties

ASTM F710 for the Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring suggests concrete with a moderate to moderately low water cement ratio (0.40 to 0.45) can be used to produce floors slabs that are easily placed, finished, and dried. Workability of the concrete can be improved by utilizing water reducing admixtures.

With respect to surface finish, specify a finish that is appropriate for the flooring placed and the minimum appropriate flatness. Do not over-finish the slab. At times, floor finishers can burnish the floor by repeated hard troweling. This densifies the surface and can slow the moisture leaving the slab.

Curing

Slabs should not be wet cured by ponding water or by placing wet burlap over the concrete. Curing compounds or cure-and-seal materials also should not be used. These products slow the initial drying, resulting in longer drying times. Also, the products typically have to be removed prior to placing the floor adhesive. The slab should be cured by utilizing waterproof paper, plastic sheets, or a combination of the two, for 3 to 7 days.

Protection

Enclose the building to prevent rewetting of the slab caused by rainwater, runoff from adjacent slopes, or landscaping water. Exposure to water from outside of the structure as well as interior sources, such as curing, wet grinding or sawing, and cleaning, will add water absorbed by the concrete and reset the drying clock. Enclosing the building also allows for HVAC systems to be utilized to assist with the drying of the slabs. Since ambient conditions have a great effect on the drying rates of the concrete, exposure to warmer, less humid air aids in drying.

Moisture Mitigation

Because some time-critical schedules do not allow for concrete to dry fully, a moisture mitigation system may be specified. These systems are externally applied to the surface of the concrete to produce a moisture state that allows the adhesive to bond to the substrate surface (ACI 302.2R-06).

Conclusions

The specification and construction of a properly designed elevated floor system is possible if a number of factors are considered. The materials and design of the substrate, flooring adhesive, and flooring materials must all be evaluated to check for compatibility with each other and their ability to perform within the desired construction schedule. The timeline must be realistic for the materials involved. If the materials cannot perform in the desired timeframe, other strategies must be incorporated to improve the performance.

This is a team effort. It is important to communicate during the design, planning, and construction phases of the project. A pre-construction meeting with all involved parties present is recommended to communicate the expectations of everyone involved. With proper planning and a well-informed team, a successful project can easily be accomplished.▪

References

Rule 1168 – Adhesive and Sealant Applications, Amended January 2005: South Coast Air Quality Management District (SCAQMD), State of California, www.aqmd.gov.

ASTM F710-08 Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring, ASTM International, West Conshohocken, Pennsylvania, 2008.

Portland Cement Association, www.cement.org.

Fire Resistance Directory, Volume 1, Underwriters Laboratories, Inc., Northbrook, Illinois, 2009, pp 219-222.

ACI 302.2R-06 Guide for Concrete Slabs that Receive Moisture-Sensitive Flooring Materials, American Concrete Institute, Farmington Hills, Michigan, 2006.