Use of Innovative Software Helps Reduce Costs and Project Delivery Time

Set to be the United Kingdom’s second tallest building next to the Shard skyscraper, 22 Bishopsgate is a 62-story, 912-foot (278-meter) glass-clad tower that will sit at the center of a cluster of high rises in London’s Financial District. PLP Architecture conceptually designed the building, featuring 120,000 square meters (nearly 1.3 million square feet) of office space, retail shops, fitness centers, educational facilities, restaurants, and an open viewing terrace and observatory, in a bid to create the city’s first vertical village. WSP Parsons Brinckerhoff (WSP) was retained to manage the structural modeling and design, as well as provide multi-discipline engineering services to ensure sustainability, achieve a BREEAM excellent rating, and be the first in London to adopt the WELL Building Standard promoting the health and well-being of the building’s 12,000 occupants.

London’s first vertical village featuring office space, shops, restaurants, medical and educational facilities, and a public observatory.

The £1.5 Billion (approximately $1.9 Billion US) project required that 22 Bishopsgate be built on the site of a previously unfinished building, the Pinnacle, where the foundation, basement, and partially constructed core (called the “stump”) of this structure remained. The new tower needed to incorporate the former Pinnacle’s foundation and three stories of basement structures. In addition to the site constraints amid several high-rise buildings, a tight timeline, and budget requirements, “The challenge was to marry the superstructure, which did not correspond to where the foundations were,” explained WSP structural engineer Diego Padilla Philipps. The project team used Bentley Systems’ RAM Structural System and RAM Concept to provide WSP an integrated BIM solution to structurally design an efficient building that would be larger than, and completely different from, the Pinnacle design.

Recycling the Foundation

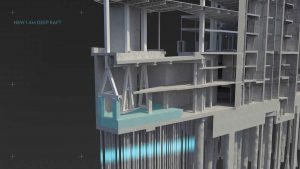

Working cooperatively with local structural specialists, WSP chose to demolish the seven-story Pinnacle stump and analyze the interaction between the new design and the existing basement and foundation structural elements to determine what could be salvaged. Said Philipps, “We used RAM Concept to analyze the complicated geometry and export the spring reactions for the piles from the geotechnical analysis, and tried to make them compatible and interpret how the foundation was going to work.” Since the core footprint of 22 Bishopsgate is larger than the Pinnacle, the team determined that if they added new raft and pile caps to adapt the existing supports to transfer the structure’s weight, they could establish the additional foundation capacity for the bigger building while still using 100 percent of the former Pinnacle’s foundation. Saving and reusing the existing foundation not only reduced costs but also minimized impact to the environment on this multi-use tower project.

Innovative Solutions

Because the footprints for the two buildings did not match, the team decided that the basement was the best place for the substructure load transfer structures. Using RAM Concept, WSP analyzed and modeled the three basement floors to determine how to build around and through them to optimize the transfers. On the north side of the structure, the project team designed three columns to support the 62 stories. WSP designed a raft to spread the loads for the three columns into the existing foundations. However, the raft could not support the loads, so the project team used A-frames to distribute the weight appropriately.

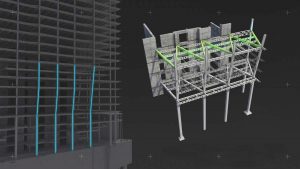

Due to the waste management strategy implementation on the south side of the structure, the team could not use a vertical column going down to the foundation. WSP needed to incorporate an inclined column on this side of the structure, with high-strength cables to tie the column to the core.

Similar to the basement transfers, the superstructure also required some elements to be transferred using inclined columns. However, while the basement’s inclined column was tied to the core, the superstructure did not lend itself to this type of support because the high-strength cables would interfere with the services running through the openings at these levels. To resist the lateral forces generated by an inclination spanning 50 stories high, WSP used RAM Structural System to analyze and design a horizontal transfer system where the floor plates behaved horizontally.

Having columns at different positions throughout the superstructure, without corresponding foundations in the substructure, required WSP to design concrete walls all the way around to transfer the loads. The integrated software solution WSP used resulted in an innovative design solution that salvaged the existing basement structure.

BIM Advancements

To design the floors and determine the optimal shape of the overall structure, WSP linked RAM Structural System with Fabsec and Revit. Stated Philipps, “At some point in the design of the project, it was requested that we transfer all the elements to Fabsec… so we integrated RAM with Fabsec.” The team used RAM Structural System to analyze the steel frame for the floors and exported all the elements to Fabsec for design. Linking the two technologies allowed for the integrated design of the steel-plated floor beams, and facilitated seamless collaboration and information mobility with the client to meet the project’s changing demands.

Furthermore, the team conducted up to 70 iterations to achieve the required design. With each iteration taking one or two engineers a week to model, WSP used Revit integrated with RAM, through Bentley’s Integrated Structural Modeler, to produce drawings and models simultaneously. This integrated approach accelerated the structural design process, reducing engineering and modeling time from 70 to 43 weeks, a reduction of nearly 40 percent.

Interoperable Technology Drives Design

Using Bentley’s interoperable applications for schematics through to construction design provided efficient and economical solutions within the tight time frame, as well as ensured strict compliance with European regulatory codes. The final design for 22 Bishopsgate was a structural steel frame that was 15 percent lighter than the Pinnacle design, with an efficient shape housing 30 percent more floor space and designed to achieve an excellent BREEAM rating and promote the health and well-being of its occupants.

Fast Facts

- 22 Bishopsgate is set to be London Financial District’s tallest building and the city’s first vertical village designed to promote the health and well-being of its occupants.

- WSP used RAM to design the structural system of the multi-use tower, incorporating existing structural elements from the previous Pinnacle building.

- The final design was 15 percent lighter and 30 percent larger than the original Pinnacle design.▪